In the ever-evolving world of manufacturing, precision and durability stand as pillars of success. Among the many facets of this industry, gear machining holds a critical position. At the heart of this process is LS Hardware Tech Co., Ltd, a company renowned for its commitment to excellence in gear manufacturing and precision parts production. With over two decades of experience, LS Hardware continues to set benchmarks in the field of CNC gear machining and gear grinding services.

Gear machining is fundamental to industries that require intricate machine components to function seamlessly. Precision gear cutting techniques play a pivotal role in ensuring that each gear manufactured meets the exacting standards demanded by various sectors, including automotive, aerospace, and industrial equipment. The strategic combination of gear shaping techniques and modern technology allows for the creation of gears that offer impeccable performance. LS Hardware Tech Co., Ltd's extensive expertise in gear manufacturing ensures that clients receive products characterized by high precision and unparalleled durability.

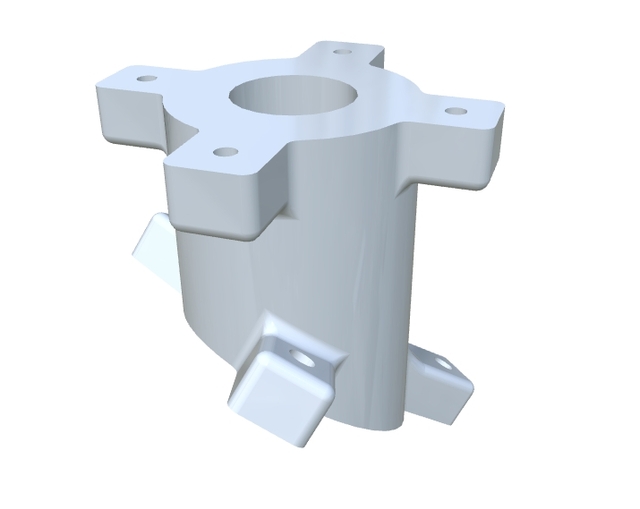

Central to LS Hardware Tech's offering is their latest innovation, the Precision Threaded Shaft. Engineered with a focus on accuracy, this shaft is crafted from high-grade materials and features expertly machined threads on both ends. Its sleek cylindrical form and corrosion-resistant finish not only ensure longevity but also enhance integration into complex assemblies, making it ideal for custom engineering projects and precision machinery. The Precision Threaded Shaft embodies LS's commitment to quality, as it effortlessly blends functionality with aesthetics, thus elevating the design and operation of any equipment into which it is integrated.

The significance of gear machining extends beyond manufacturing alone. It represents the essence of precision engineering and innovation. LS Hardware’s proficiency in spline machining and gear hobbing enhances their capability to serve over 5,000 clients globally, solidifying their position as a trusted partner in hardware and plastic parts manufacturing across more than 150 countries and regions. The company's ISO 9001:2015 certification is a testament to their dedication to maintaining high standards of production efficiency and quality assurance.

LS Hardware’s commitment to innovation is further highlighted by the advanced machining centers housed within their factory. With over 100 high-end centers, the company delivers on its promise of high production efficiency. This infrastructure enables the mass production of high-precision parts, thereby meeting the diverse needs of industries from consumer electronics to medical devices. By continually refining processes and capabilities, LS Hardware Tech Co., Ltd remains at the forefront of technology, ensuring that they not only meet their clients' needs today, but also anticipate the challenges of tomorrow.

The synergies between the company’s extensive experience in precision gear machining and innovative product offerings like the Precision Threaded Shaft underscore their promise to clients: delivering solutions that empower ideas. Whether it’s through the delivery of custom-engineered parts or precision components, LS Hardware’s mission is to transform concepts into tangible, reliable outputs.

In conclusion, gear machining is not merely a process; it is an art form shaped by experience and innovation. LS Hardware Tech Co., Ltd excels in this domain, offering a seamless blend of advanced gear manufacturing techniques, state-of-the-art technology, and timeless design to create products that not only perform but also inspire. As they continue to evolve and expand their capabilities, LS Hardware remains a pioneering force, dedicated to bringing precision and excellence to industries worldwide.

Mastering Gear Machining with LS Hardware Tech Co., Ltd

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Gear Machining: Mastering Precision & Innovation Techniques

Revolutionize Gear Production with Gear Machining Services

Precision Gear Machining Services by LS Hardware Tech

Explore Top Gear Machining Services for Precision and Innovation

Gear Machining: Precision and Innovation in Manufacturing

Advanced Gear Machining Techniques for Enhanced Precision and Performance

Gear Machining Excellence: LS Hardware Tech<111>s Innovations

Advanced Gear Manufacturing: LS Hardware Tech Co., Ltd

Gear Machining Services: Precision and Efficiency Unveiled

Gear Machining Services: Precision & Custom Solutions