In the world of manufacturing and construction, bending techniques play an essential role in shaping and assembling materials into functional and aesthetically pleasing forms. Whether you're working with metal bending, plastic bending, or utilizing advanced bending machinery, understanding the bending process is crucial for achieving precision and maintaining the integrity of the materials. With the advancement in technology, new tools and methods such as tube bending, sheet metal bending, and pipe bending have emerged, offering a myriad of solutions for diverse applications.

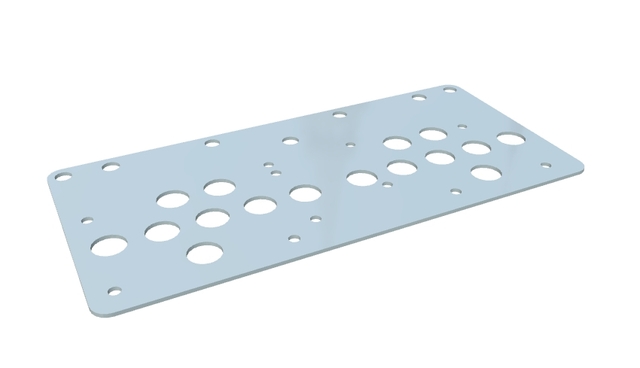

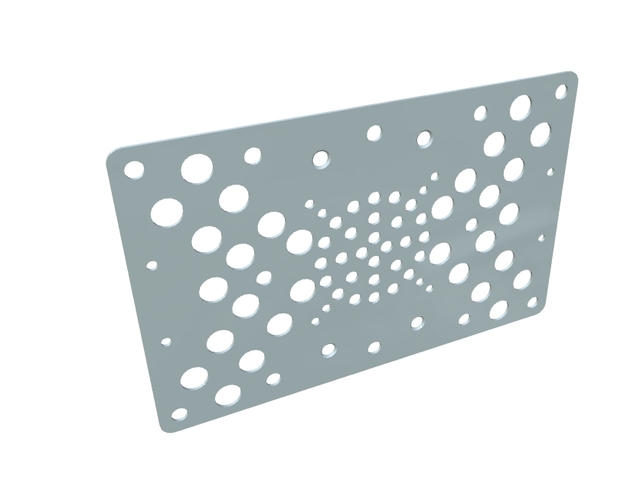

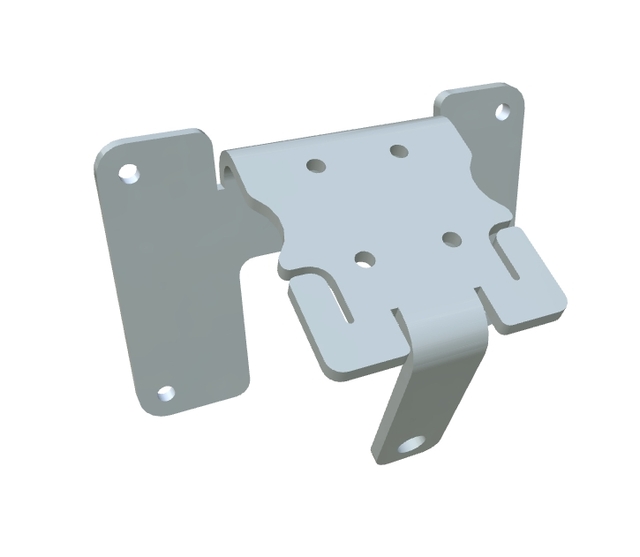

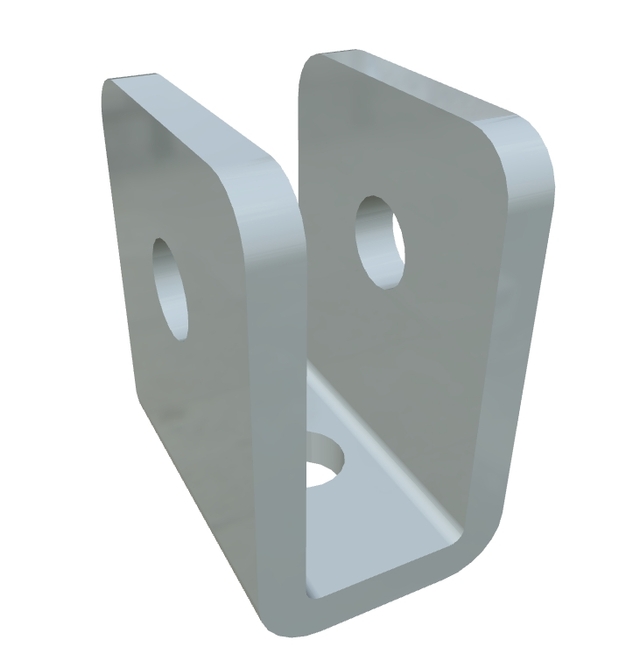

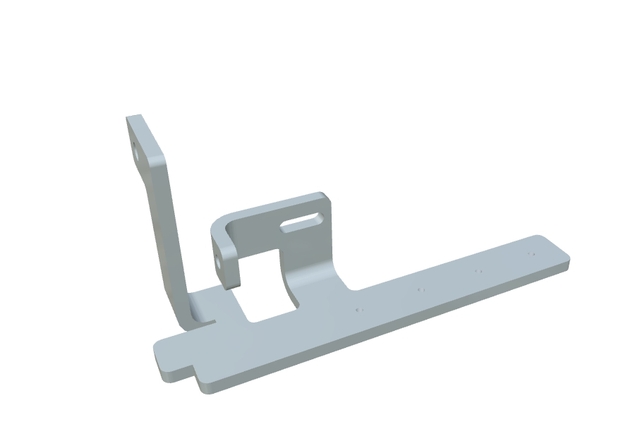

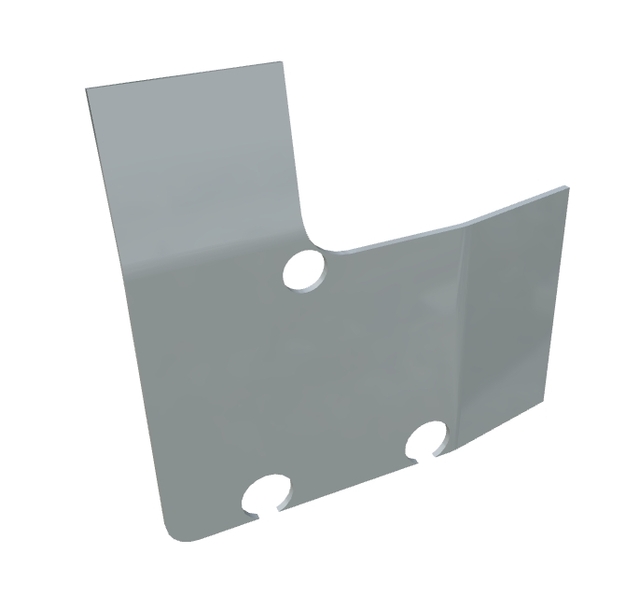

A prime example of how bending techniques are essential in product development is the introduction of our latest precision-engineered connector plate. Made from high-grade stainless steel, this connector is designed to withstand the harshest of conditions, thanks to its exceptional durability and corrosion resistance. The use of bending in its design ensures that the plate maintains its strength while offering versatility in both indoor and outdoor settings. This is particularly important as materials used in different environments require adaptability and resilience, which bending techniques help achieve.

Furthermore, the connector plate's strategic design is enhanced by the precise placement of holes, providing flexible mounting options. This feature showcases the importance of the bending process in ensuring that such components can seamlessly integrate into various projects. Whether in complex frameworks or simple reinforcements, the ability to bend the material accurately and efficiently contributes to the overall structural integrity of the assembly.

Modern architects, builders, and DIY enthusiasts will find the design of this connector plate appealing not only because of its functionality but also due to its minimalist aesthetic. By employing advanced bending machinery, the plate is crafted to meet contemporary design standards without compromising on its load-bearing capabilities. This kind of innovation in product design is essential in today’s competitive market, where both performance and appearance are crucial.

The world of bending techniques is vast and varied, with each method and tool bringing unique advantages to the construction table. For instance, tube bending is widely used in creating piping systems and canopies due to its ability to produce smooth and consistent curves. Similarly, sheet metal bending is key in automotive and aerospace industries for creating complex components that require precision and strength.

Pipe bending techniques have evolved significantly, allowing for more intricate and robust piping systems that can handle high-pressure applications. By understanding these various methods, engineers and builders can select the appropriate bending technique to suit their specific needs, ultimately leading to more efficient and effective solutions.

In summary, the importance of bending techniques in product design and construction cannot be overstated. From metal and plastic bending to advanced machinery and processes, these techniques provide the foundation for creating durable, reliable, and aesthetically pleasing components like our precision-engineered connector plate. As technology continues to advance, so too will the capabilities of bending techniques, opening new possibilities for innovation and craftsmanship across innumerable industries.

Mastering Bending Techniques: Essential in Modern Design

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering Bending Techniques: Essential in Modern Design

Mastering Bending Techniques for Innovative Designs

Mastering Bending Techniques for Modern Elegance

Mastering Bending Techniques with Precision Router Base Plate

Metal Bending: Techniques for Modern Engineering Design

Bending Technology: Revolutionizing Metal and Pipe Bending

Expert Bending Techniques for Advanced Manufacturing

Mastering Bending Techniques for Modern Applications