In the realm of architectural innovation and construction, mastering welding techniques can often be the difference between durable, long-lasting structures and those that fall apart over time. Welding is not just about joining metals; it is a sophisticated skill that ensures safety and excellence in any physical structure. At its core, welding involves specialized techniques that utilize a variety of welding equipment and materials designed to meet specific industry standards and needs.

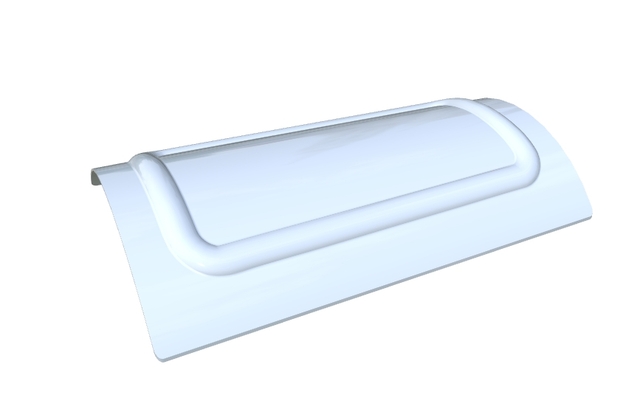

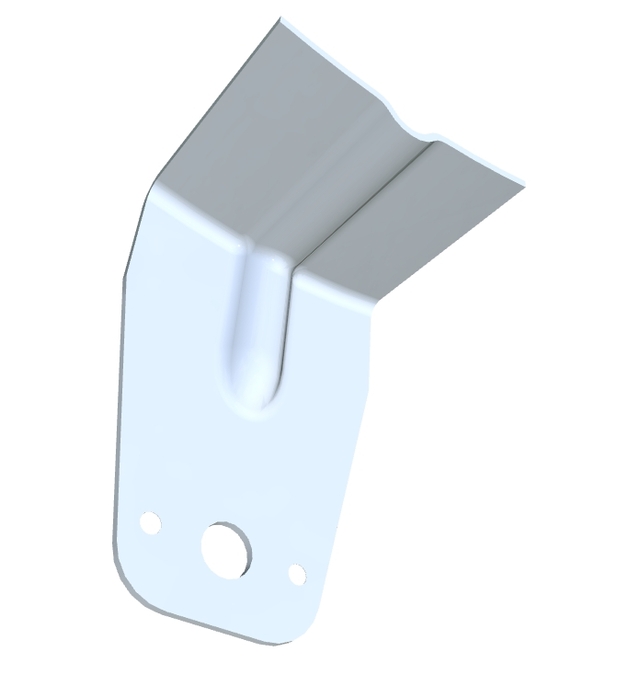

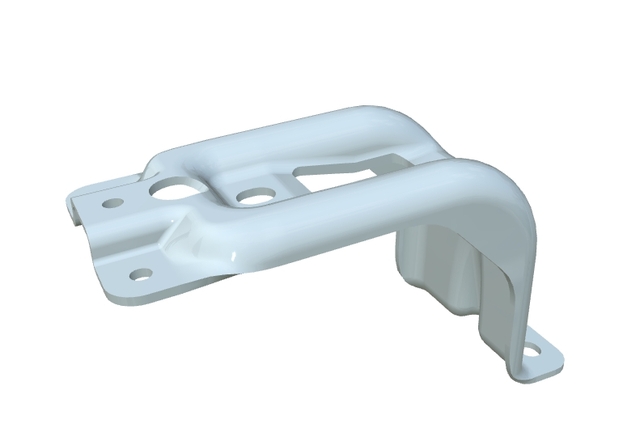

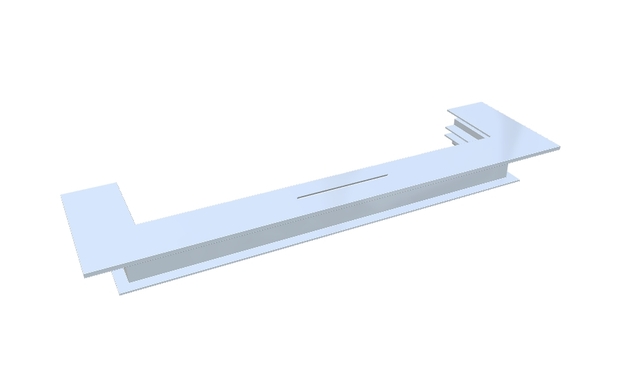

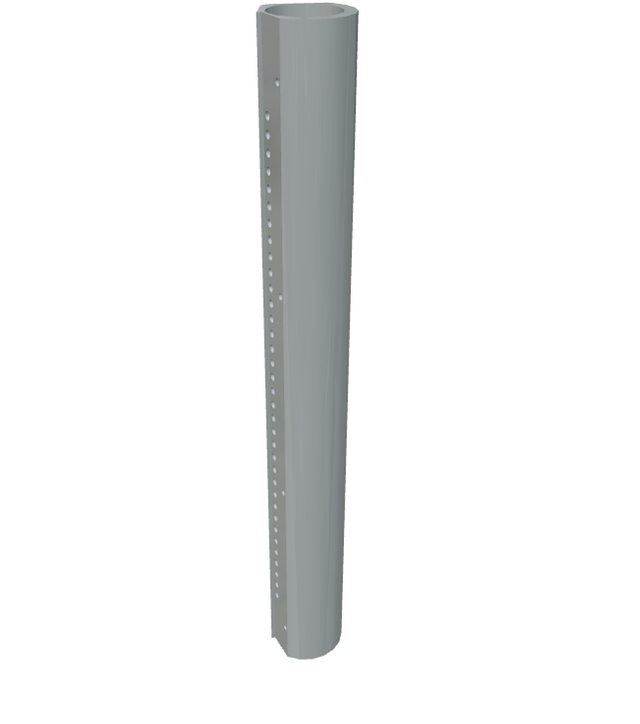

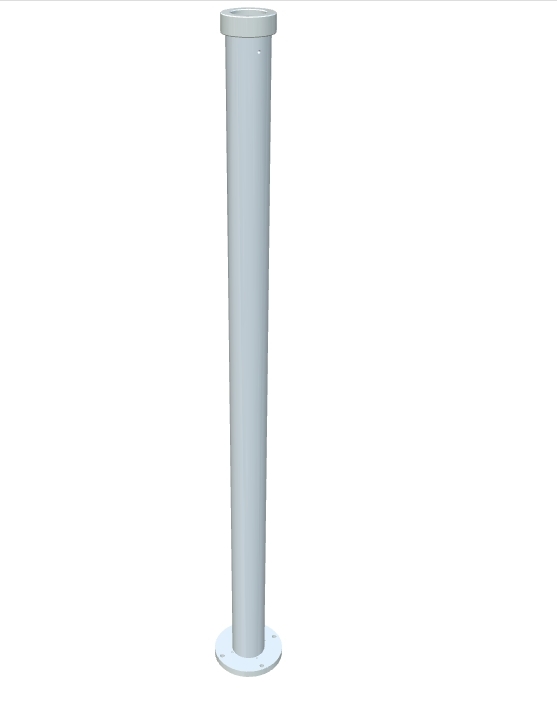

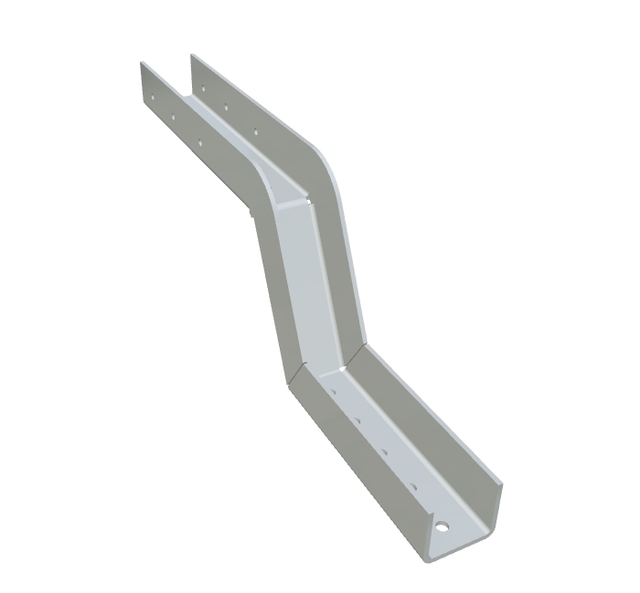

These welding techniques are critical to creating reliable architectural brackets, such as our latest product offering. This versatile architectural bracket boasts a minimalist design crafted with unmatched precision, offering both structural support and style that is second to none. With a polished metallic finish, our bracket elevates any space, fitting seamlessly into modern interiors where aesthetic appeal and functionality are paramount.

In-depth knowledge of welding processes is a prerequisite for producing high-quality components like our new architectural bracket. This knowledge begins with understanding the different welding techniques available. Some of the most common types include MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and Stick welding. Each method has its own advantages and uses, depending largely on the materials involved and the structural requirements of the project at hand.

Safety in welding is another crucial aspect that cannot be overstated. Employing appropriate welding safety measures ensures that the integrity of the work is maintained and that the craftsmen involved are protected. Proper usage of welding safety equipment such as gloves, helmets, and eye protection is essential during any welding process, helping to prevent common hazards like burns, eye damage, and inhalation of harmful fumes.

For those seeking to excel in the field of welding, obtaining welding certification is indispensable. Certification not only demonstrates proficiency in various welding techniques but also opens the door to numerous welding jobs and opportunities. Given the rigorous welding standards prevalent in the industry, certified welders are in high demand, tasked with ensuring projects meet the highest levels of quality and safety.

Welding standards form the backbone of any welding project, ensuring consistency, safety, and durability of the work. Adhering to these standards guarantees that all welding projects, from monumental steel frameworks to our sleek architectural bracket, are executed with precision and reliability.

Engineered for durability, our architectural bracket exemplifies the pinnacle of welding excellence. It seamlessly integrates into both residential and commercial spaces, embodying strength and elegance. Whether supporting a new residential balcony or a commercial railing, our brackets meet and exceed welding standards without compromising on design sophistication.

Designed for those who appreciate quality in their architectural components, our bracket underscores the importance of selecting products that meld superior craftsmanship with high standards. This approach not only enhances the visual appeal of a space but ensures robustness and safety in every welded joint.

In conclusion, whether you are a seasoned welder or just entering the profession, a comprehensive understanding of welding techniques is essential. By dedicating time to learning about welding equipment, safety, materials, and certification, welders can produce structures that not only meet but exceed expectations in quality and durability. With the right techniques in hand, creating stunning, structural masterpieces like our architectural bracket becomes a true form of art, embodying the epitome of functional beauty in modern design.

Master Welding Techniques for Architectural Brackets

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering Welding Techniques for Industrial Excellence

Exploring Types of Welding: Techniques, Safety, and More

Welding Safety: Ensuring Safe Welding Practices

Mastering Welding Techniques: Types, Safety, and Equipment

Master Welding Techniques for Architectural Brackets

Mastering Welding Techniques: Elevate Your Projects

Mastering Welding Techniques for Modern Urban Safety

Mastering Welding Techniques: Weld Safely with Innovation