In today's highly competitive manufacturing landscape, achieving precision in gear machining is not just a necessity but a hallmark of superior engineering. Gears, the pivotal components in machinery, require meticulous production processes to ensure optimal functionality and longevity. At the heart of this industry evolution is LS Hardware Tech Co., Ltd, a leader in high-quality precision gear machining, bringing over two decades of expertise to the forefront. As a company dedicated to innovation and client-oriented solutions, LS Hardware Tech is pioneering advancements in gear manufacturing and machining processes.

**LS Hardware Tech Co., Ltd: A Heritage of Excellence**

Founded by Mr. Nick Zhang and a team of seasoned engineering experts, LS Hardware Tech Co., Ltd exemplifies dedication to craftsmanship in the realm of gear manufacturing. With state-of-the-art facilities encompassing over 100 high-end machining centers, the company stands as a beacon of high production efficiency and precision output. ISO 9001:2015 certification further solidifies their commitment to quality, with a client base spanning more than 150 countries worldwide. From automotive to aerospace, LS meets the diverse needs of thousands of clients, offering solutions tailored to specific industrial requirements.

**Innovations in Gear Machining**

In the pursuit of perfecting gear machining, LS Hardware Tech offers a comprehensive range of services including CNC gear cutting, gear hobbing, and gear shaping. These services form the backbone of precision gear machining, ensuring that each gear produced meets stringent performance and durability standards. CNC gear cutting, for instance, utilizes cutting-edge technology to produce gears with exact specifications and unparalleled precision. Gear hobbing and shaping, meanwhile, are instrumental in crafting the intricate teeth profiles that are essential for smooth operation and noise reduction.

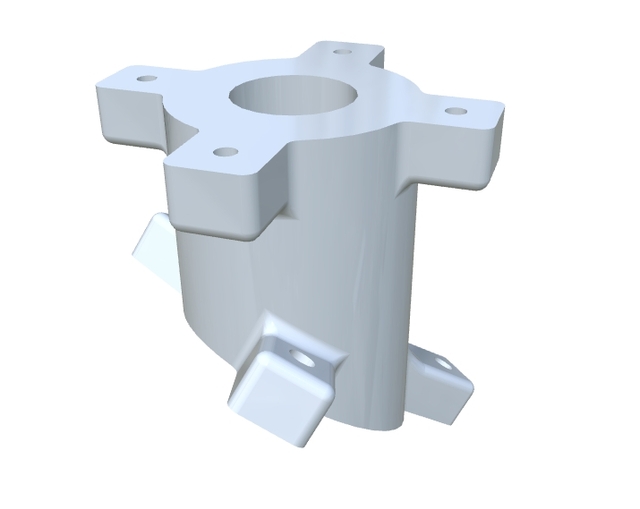

The company's latest product, the Precision Mounting Bracket, exemplifies their commitment to innovation and quality. Crafted from high-grade materials, this mounting solution incorporates strategically placed mounting holes that simplify installation. Its central circular cut-out is designed for seamless component integration, making it a versatile option for projects requiring quick adaptability and robust construction. These features, combined with a minimalist design, make the Precision Mounting Bracket ideal for use in demanding spaces, where functionality and aesthetics must coexist seamlessly.

**Custom Gear Production: Precision Meets Flexibility**

Recognizing the diverse demands of their clientele, LS Hardware Tech Co., Ltd excels in custom gear production—an area where precision gear machining and versatility merge. Whether gearing solutions require adaptation for specific industrial applications or innovation in problem-solving, LS’s expansive manufacturing capabilities ensure that these requisites are not only met but exceeded. The company’s ethos of continual process advancement serves as the cornerstone for delivering tailor-made solutions that align precisely with customer expectations and operational needs.

As the engineering and manufacturing sectors continue to evolve, LS Hardware Tech remains poised to lead. Through ongoing investment in technology, expertise in gear machining, and an unwavering commitment to quality, they are well-equipped to handle the complexities of modern manufacturing challenges. For industries that demand quality, reliability, and exceptional performance, LS Hardware Tech Co., Ltd stands as a trusted partner, ready to usher in a new era of precision gear machining and custom gear solutions.

Achieving Excellence in Gear Machining and Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Gear Machining, 5-Axis CNC Machining, CNC Turning, CNC Milling, CNC Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.