Plastic injection molds are important toolsin the production of plastic products. The selection of their materials is directly related to the performance, lifespan and quality of the final product of the mold. Injection molds are made of a wide variety of materials, mainly including metal materials, non-metallic materials and composite materials. The Longsheng team will take you into the material world of plastic injection molds.

What is a plastic injection mold?

A plastic injection mold is a metal mold specially designed for use in theinjection molding process. Through precise modeling and structural design, it can inject molten plastic into the mold cavity under the pressure of the injection molding machine, and form plastic products of the required shape and size after cooling and solidification. Injection molds usually consist of a movable mold and a fixed mold. They have the characteristics of high precision, high strength and durability. They are an indispensable and important tool in the plastic processing industry.

What Materials Are Used in plastic injection molds?

Plastic injection molds use a variety of materials designed to meet different production needs, process requirements and cost considerations. Here are some common plastic injection mold materials and their characteristics:

1.Metal materials

(1)Titanium

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds in the aerospace field have strict requirements for lightweight, corrosion resistance and heat resistance. |

(2)Steel

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds are widely used in automotive, electronics, medical and other fields. |

(3)Stainless steel

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds in food processing, chemical industry, medical and other fields are particularly suitable for applications where corrosion resistance is required. |

(4)Aluminum

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds in electronic products, automotive parts and other fields where lightweight and heat dissipation performance are required. |

(5)Magnesium

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds in electronic product casings, automotive parts and other fields where lightweighting is required. |

(6)Zinc alloy

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds in toys, daily necessities and other fields have certain cost requirements. |

(7)Cold rolled steel

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds that need to withstand greater stress and require certain accuracy, such as injection molds for automotive parts and industrial equipment components. |

(8)Chrome nickel alloy

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds in the chemical, medical and other fields especially require corrosion resistance and high temperature stability. |

(9)Brass

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds in the fields of decorations, artworks, etc., where there are certain cost requirements. |

(10)Copper

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds that require rapid heat dissipation and wear resistance, such as injection molds for electronic product casings. |

(11)Bronze

| Characteristic | Application advantages | Applicable scenarios |

|

|

Injection molds that need to withstand greater stress and wear, such as large injection molds and injection molds for industrial equipment parts. |

2.Plastic material

The materials used in plastic injection molding technologyare mainly plastics, especially thermoplastics. This type of plastic can soften and flow when heated during the plastic molding process, making it easier to inject into the mold, and solidifies to maintain its shape after cooling. Here are some common molding plasticmaterials:

Silicone Rubber:Silicone molding is used for products requiring flexibility and heat resistance, such as medical devices.

ABS:ABS is one of the most commonly used materials in injection molding. It is widely used in the manufacturing of casings and components for automobiles, home appliances, and electronic products due to its good mechanical properties, impact resistance, chemical resistance, and easy processability.

PC:PC has excellent transparency, impact resistance, heat resistance and dimensional stability. It is often used to make products that require high transparency and high strength, such as optical discs, eyeglass lenses, safety helmets, displays for electronic equipment, etc.

PA:Nylon material has high strength, wear resistance, oil resistance and good self-lubricating properties. It is often used to manufacture bearings, gears, pipes, cable sheaths and other parts that need to withstand mechanical stress and wear resistance.

POM:POM is known for its high hardness, high rigidity and excellent wear resistance. It is often used to manufacture precision parts, gears, bearings, sliding parts, etc.

PMMA:Also known as organic glass, it is often used to make lenses, display boxes, signs, etc. due to its good optical properties, transparency and weather resistance.

PET:PET is mainly used to make beverage bottles, food packaging, etc., but in injection molding, it is also used to make some products that require high transparency and good barrier properties.

PBT and PETG:These materials have good heat resistance, chemical resistance and mechanical properties and are commonly used in the automotive, electronics and home appliance industries.

Types of injection molds and their material requirements

There are manytypes of injection molds, each with its own specific application scenarios and material requirements. The following is a detailed explanation of the types of injection molds and their material requirements:

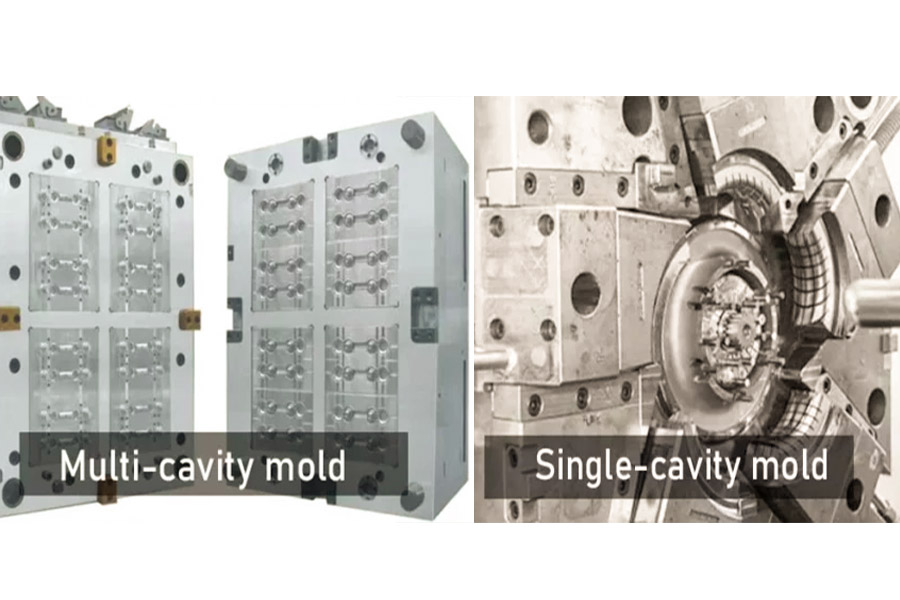

1. Single cavity mold

- Application:Single-cavity molds are mainly used for small batch production, especially when the plastic parts are large, precision requirements are high, or trial production is required. Due to its simple structure, low manufacturing cost and short cycle time, single-cavity molds are very suitable for this type of scenario.

- Material:The material of single cavity mold is usually steel or aluminum. Steel molds have high hardness and wear resistance and are suitable for producing high-precision and high-quality plastic parts. Aluminum molds have lighter weight and good thermal conductivity, which helps shorten the injection molding cycle and improve production efficiency.

2. Multi-cavity mold

- Advantages:Multi-cavity molds can process multiple products at the same time in the same production cycle, thus greatly improving production efficiency. In addition, multi-cavity molds have higher material utilization and lower production costs, which is particularly important for companies that require mass production.

- Material:Multi-cavity molds need to withstand greater injection pressure and impact, so their material is usually hardened steel. Hardened steel has high hardness and toughness, ensuring that the mold maintains its shape and dimensional stability over long periods of use.

3. Hot runner mold

- Materials:Hot runner molds need to have good thermal management properties to ensure that the plastic melt maintains the appropriate temperature in the mold. Therefore, copper-based alloys are usually selected as materials for hot runner molds. Copper-based alloys have high thermal conductivity and good corrosion resistance, which can ensure the stability and reliability of hot runner systems.

- Application:Hot runner molds have been successfully used to process various plastic materials, including electronics, automobiles, medical, daily necessities, toys, packaging, construction and office equipment.

4. Customized plastic injection molds

- Material selection:The material selection of customized plastic injection molds is very flexible and can be customized according to the shape, size, accuracy requirements and production environment of the plastic parts. Common materials include steel, aluminum, copper-based alloys, and polymer materials.

- Application:Customized plastic injection molds are suitable for various special applications, such as the production of high-precision parts, complex-shaped parts, large parts, and parts requiring special properties (such as high temperature resistance, wear resistance, etc.).

What are the methods of making plastic injection molds?

There are two main methods of constructing molds:computer numerical control (CNC) machiningand electrical discharge machining (EDM).

1.CNC machining

CNC machining for making molds is typically an automated process that utilizes machining and cutting equipment to shape the mold to specified dimensions following computer-programmed instructions. CNC systems convert in-depth design files into programmable instructions that the CNC machine reads and executes. Product design engineers create precise virtual product designs using computer-aided design (CAD) software that specifies every construction detail.

Once theCAD designis complete, mold engineers can use computer-aided manufacturing (CAM) software to convert the CAD into instructions that the CNC hardware can understand. The generated commands are then uploaded into the CNC machine and the metal is precisely cut using the appropriate cutting tools to meet the exact specifications of the product design.

2.Electrical Discharge Machining(EDM)

Like laser cutting, EDM does not require or use mechanical force to cut metal. Instead, it utilizes electrodes, usually made of graphite, that are mounted on the EDM machine and placed over a mold submerged in a dielectric fluid.

The electrode is then lowered onto the mold and a controlled power source is used to break and disperse the metal in the area opposite the electrode without touching the mold. Although typically slower, the EDM process can produce shapes not possible with traditional CNC machining.

FAQs

1.What plastic material is used in injection molding?

Injection molding is a widely used plastic molding method that is suitable for a variety of plastic materials. Common plastic materials used for injection molding include: ABS, polyethylene (PE), polypropylene (PP), polystyrene (PS), polycarbonate (PC). In addition, there are acrylic (PMMA), nylon polyamide (PA), polyoxymethylene (POM), etc. are also common injection molding plastic materials.

2.What are plastic injection molds made of?

Plastic injection molds are made of mold steel specifically used for molding plastic products. These mold steels usually have high hardness, wear resistance and toughness to ensure that the mold can maintain its shape and dimensional stability over long periods of use. Common mold steel materials include carbon structural steel, carbon tool steel, alloy tool steel and high-speed steel.

3.What materials are used to make Mould?

Generally speaking, the material the mold is made of is selected based on its application scenario and performance requirements. In addition to the mold steel mentioned above, other materials, such as aluminum alloy, copper alloy, etc., may also be used for molds with certain special requirements. These materials are selected to meet the hardness, wear resistance, corrosion resistance, thermal conductivity, and processability requirements of the mold.

4.What equipment is used in injection molding?

The main equipment used in injection molding is an injection molding machine (also known as an injection molding machine). Injection molding machine is a device used to inject molten plastic into a mold and obtain a plastic product of the desired shape after cooling and solidification. It is mainly composed of injection system, mold clamping system, hydraulic transmission system, electrical control system, etc. The injection molding machine can automatically complete the plastic melting, injection, pressure holding, cooling and demoulding processes according to preset programs and parameters.

Summary

Injection molds are important tools in the plastic processing industry. Through precise design and efficient work processes, they can produce a variety of high-quality plastic products. During the injection molding process, it is necessary to pay attention to multiple points such as mold design, injection molding machine selection, injection molding process and subsequent processing to ensure processing quality and efficiency. Through continuous technological innovation and improvement, injection molds will be applied and developed in more fields.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

This article was written by multiple LS contributors. LS is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.