Injection molding, as an indispensable part of modern manufacturing, has become a mainstream process for the production of plastic products due to its high efficiency, flexibility and cost-effectiveness. However, to maximize the benefits of this process and ensure product quality and production efficiency,key design and engineering considerations in injection moldingmust be carefully evaluated and optimized. Here are a few key factors to focus on during the injection molding process.

What is Injection Molding?

In the vast field of manufacturing, molding technology occupies a pivotal position.Molding meaningcovers the entire process of transforming raw materials into products with specific shapes, structures and functions. Specific to injection molding, it is an important method inplastic molding technology. It heats plastic particles to a molten state, injects them into the mold cavity under high pressure, and solidifies after cooling to produce various precision and complex plastic products.

In addition, silicone molding, as another special molding technology, focuses on the processing of silicone materials. Silica gel is widely used in medical, food, electronics and other fields because of its excellent high temperature resistance, aging resistance, environmental protection and non-toxic properties. The silicone molding process also requires precise control of temperature, pressure and other parameters to ensure the quality and performance of the final product. Whether it is injection molding,plastic molding or silicone molding, they are all important components of molding technology. Each plays an irreplaceable role in different fields and jointly promotes the progress and development of the manufacturing industry.

What are the Key Design Considerations for Injection Molding?

Key design considerations for injection moldinginclude mold design, wall thickness, gate construction, part ejection and draft angles, as well as tolerances and shrinkage.

1. Mold design

Mold design is the core part of injection molding, which determines the shape, size and accuracy of the product. The shape of the mold must match the design of the product to ensure that the product can be formed smoothly. The design of the mold also needs to take into account factors such as product complexity, wall thickness, and dimensional accuracy. The runner is the channel through which the plastic melt flows from the injection machine nozzle to the mold cavity. The design of the runner needs to ensure that the plastic melt can fill the mold cavity evenly and quickly while reducing flow resistance and pressure loss. The gate is the channel that connects the runner and the cavity. It controls the flow and speed of the plastic melt into the cavity. The design of the gate needs to take into account factors such as the shape, size, wall thickness of the product, and the fluidity of the plastic. By optimizing gate design, product defects such as sink marks, bubbles, deformations, etc. can be reduced and production efficiency improved.

2. Wall thickness

Wall thickness is considered to be one of the core factors that determinethe quality of injection molded products. Since thin-walled plastic parts have special structures and complex shapes, appropriate process parameters must be adopted in production to ensure product quality. This substance has a significant impact on the flow characteristics of the plastic, the cooling cycle and the mechanical strength of the final product:

- Plastic flowability:Due to the thicker wall thickness, the plastic melt takes longer to completely fill the mold cavity, which may increase resistance to flow and thus adversely affect the molding quality of the product.

- Cooling time:Increased wall thickness results in longer cooling times because thicker walls mean the plastic takes longer to cool to the right temperature in the mold. This not only increases the production cycle, but may also cause the internal temperature of the product to be too high, causing problems such as thermal stress and deformation.

- End-product strength:Increasing wall thickness increases the cooling time because thicker wall thickness means the plastic takes longer to cool to the proper temperature in the mold. In addition, thick wall thickness also makes the product susceptible to warping and cracking. This situation will not only extend the production cycle, but may also cause the internal temperature of the product to rise, leading to a series of problems such as thermal stress and deformation. Therefore, the wall thickness needs to be reasonably controlled to achieve the best molding effect and cost-effectiveness.

3. Street layout

The layout of the gate opening has become one of the key factors affecting the quality of injection molded products. Adopting a suitable gate layout can make the plastic flow more evenly, while also effectively reducing deformation and shrinkage: the location of the gate should be chosen in the thickest or center area of the product to ensure optimal filling and retention Pressure performance. When setting the gate, the strength or weakness experienced by the product should be avoided to prevent residual stress and deformation.

For large or complex items, several gates may be designed to ensure that the plastic flows evenly. However, too many gates will undoubtedly increase the cost of production and the complexity of the mold, so the pros and cons need to be carefully considered when choosing a strategy.

The specific size of the gate should be determined by multiple factors such as the shape, size and wall thickness of the product. A more compact watering spout can help limit the flow of plastic and avoid the formation of bubbles and sink marks; but if the gate size is too small, the resistance to flow may increase, which will damage the molding quality of the product.

4. Part ejection and draft angle

Part ejection and draft angle are key factors in ensuring that the part can be removed from the mold smoothly without damaging the finished product:

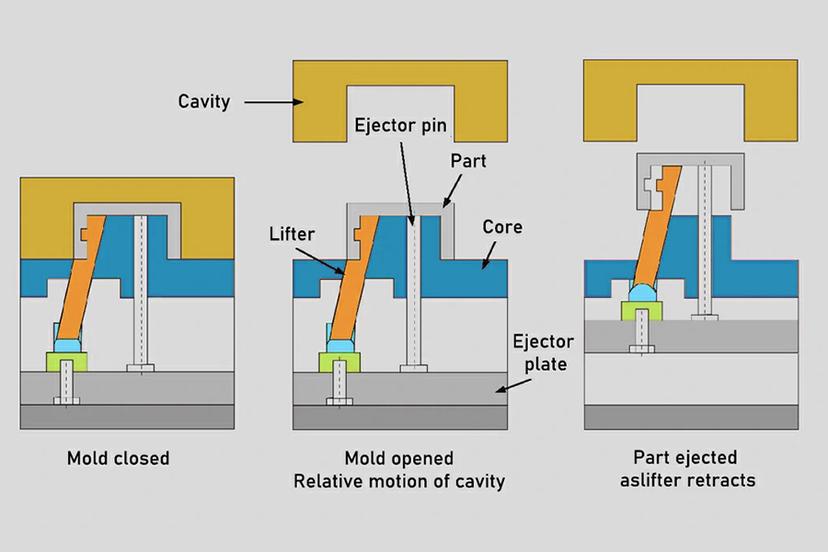

- Ejection mechanism:The ejection mechanism is the component in the mold used to eject the product from the mold cavity. It needs to be designed according to the shape, size, wall thickness and other factors of the product to ensure that the product surface will not be damaged or deformed during the ejection process.

- Draft angle:The draft angle is the ejection angle of the surface of the molded part parallel to the ejection direction of the mold. It helps reduce the frictional resistance of the product during the demoulding process and prevents the product surface from being scratched or deformed. A reasonable draft angle should be determined based on factors such as the material, shape, and size of the product.

5. Tolerance and Shrinkage

In injection molding design, plastic shrinkage and tolerance issues also need to be considered:

- Plastic shrinkage:Plastic shrinks during the cooling process, causing the size of the product to change. Therefore, the shrinkage rate of the plastic needs to be considered when designing the mold, and an appropriate tolerance range should be reserved in the product design to accommodate this change.

- Tolerance control:Tolerance control is the key to ensuring product dimensional consistency. During themold designand manufacturing process, the accuracy and dimensional tolerances of the mold need to be strictly controlled to ensure that the products produced meet the design requirements.

What Material Considerations Are Essential in Injection Molding?

Commonly usedplastic types in injection moldinginclude ABS, polypropylene, polycarbonate, etc. Let us learn about the properties and applications of these materials.

1.Plastic Selection

ABS:ABS is one of the most commonly used materials in injection molding. It is widely used in the manufacturing of casings and components for automobiles, home appliances, and electronic products due to its good mechanical properties, impact resistance, chemical resistance, and easy processability.

PC:PC has excellent transparency, impact resistance, heat resistance and dimensional stability. It is often used to make products that require high transparency and high strength, such as optical discs, eyeglass lenses, safety helmets, displays for electronic equipment, etc.

PA:Nylon material has high strength, wear resistance, oil resistance and good self-lubricating properties. It is often used to manufacture bearings, gears, pipes, cable sheaths and other parts that need to withstand mechanical stress and wear resistance.

POM:POM is known for its high hardness, high rigidity and excellent wear resistance. It is often used to manufacture precision parts, gears, bearings, sliding parts, etc.

PMMA:Also known as organic glass, it is often used to make lenses, display boxes, signs, etc. due to its good optical properties, transparency and weather resistance.

PET:PET is mainly used to make beverage bottles, food packaging, etc., but in injection molding, it is also used to make some products that require high transparency and good barrier properties.

PBT and PETG:These materials have good heat resistance, chemical resistance and mechanical properties and are commonly used in the automotive, electronics and home appliance industries.

PPSU and PEEK:These high-performance plastics are used in the manufacture of parts in extreme environments, such as medical devices, aerospace and automotive parts, because of their high temperature resistance, chemical resistance and high strength.

TPE/TPR:This type of material combines the elasticity of rubber with the processability of plastic. It is often used to manufacture seals, hoses, handles and other products that require soft touch and good sealing.

2.Material Properties for Molding

During the injection molding process, the key properties of materials include fluidity, impact resistance, heat resistance, etc. These properties directly affect the quality and production efficiency of plastic products. For example:

- Fluidity:Good fluidity helps the plastic fill and shape in the mold, improving the integrity and surface finish of the product.

- Impact resistance:Plastics with high impact resistance can resist external impact and improve the durability and safety of the product.

- Heat resistance:Plastics with good heat resistance can maintain stable performance in high temperature environments and are suitable for making products that need to work at high temperatures.

3.Silicone Molding and Specialized Plastics

When flexibility or chemical resistance is required, silicone molding and other specialty plastics can meet specific application needs:

Silicone molding

- Performance:Silicone plastichas excellent properties such as high temperature resistance, chemical corrosion resistance, wear resistance, and aging resistance, and can be used in the temperature range of -70°C to +250°C.

- Application:Widely used in medical devices (such as surgical instruments, artificial organs, catheters, etc.), food packaging (such as high-temperature cooking bags, customized plastic wrap, etc.) and electronic and electrical fields (such as cables, insulators, light-emitting diodes, etc.).

Special plastics

- Including but not limited to PPSU, PEEK, PEI and other high-performance plastics, which have excellent high temperature resistance, chemical corrosion resistance and other properties.

- Application:Suitable for making products with extremely high performance requirements, such as precision components in aerospace, medical equipment and other fields.

What are the Key Engineering Challenges in Injection Molding?

Injection molding faces many challengesincluding flow analysis and simulation, cooling and cycle time optimization, avoiding common defects, and quality control. By using advanced simulation tools, optimizing cooling system design, adjusting process parameters, and strengthening quality control, these challenges can be effectively addressed and the quality and efficiency of injection molding improved.

Flow Analysis and Simulation

During theinjection molding process, the flow behavior of the plastic melt directly affects the quality and production efficiency of the product. Defects such as uneven flow, bubbles, and uneven cooling can seriously affect the integrity and performance of the product.

Use flow analysis and simulation tools, such as Moldflow, to simulate and optimize the injection molding process. These tools help engineersoptimize mold designsby predicting key parameters such as plastic melt flow paths, fill times and pressure distribution. Through the simulation results, parameters such as injection speed, pressure and temperature of theinjection molding machinecan be adjusted to improve the flow behavior of the melt and reduce the occurrence of defects such as bubbles and uneven cooling.

Cooling and Cycle Time Optimization

Cooling time is an important part of the injection molding cycle, directly affecting production efficiency and costs. Uneven cooling can lead to quality problems such as product warping and deformation.

Optimize the design of the cooling system to ensure that the cooling water channels of the mold are evenly distributed, sufficient in number, and as close as possible to the mold cavity. This helps remove heat from the melt quickly and evenly, shortening cooling time. By adjusting parameters such as coolant temperature and flow rate, the cooling effect can be further optimized. The use of advanced cooling technology, such as rapid heat exchange systems, can significantly improve cooling efficiency and shorten production cycles.

Avoiding Common Defects

Common defects during the injection molding process include short shots, warpage, bubbles, etc. These defects can seriously affect the quality and performance of the product.

| Strategy | Description |

| Short shot | By increasing injection pressure, increasing melt temperature or optimizing mold design, the fluidity of the melt can be improved and the occurrence of short shot phenomenon can be reduced. |

| Warpage | Optimize the mold design to ensure that the product is evenly stressed during the cooling process; adjust the injection speed and pressure to avoid excessive internal stress caused by the melt in the mold; use thermosetting plastics or increase the wall thickness of the product, etc. Can effectively reduce warpage. |

| Bubbles | The generation of bubbles can be reduced by improving the venting performance of the melt, optimizing the venting system of the mold, or adjusting the injection speed and pressure. |

Quality Control Measures

- Challenge:During the injection molding process, how to ensure the consistency and accuracy of the finished product is an important challenge faced by manufacturers.

- Coping strategies:

- Raw material quality inspection:Strict quality inspection is carried out on the raw materials used in injection molding processing to ensure that they meet the prescribed standards.

- Injection molding machine equipment monitoring:By monitoring the operating status of the injection molding machine equipment, including parameters such as temperature, pressure, and injection speed, to ensure the stability and consistency of the injection molding process.

- Mold quality control:Strict quality control is carried out on the molds used in injection molding processing, including the accuracy, durability and service life of the molds. Carry out regular mold maintenance and cleaning to ensure its normal operation and extend its service life.

- Injection molding process monitoring:Real-time monitoring of key parameters during the injection molding process, such as temperature, pressure and injection speed, to ensure that the size, appearance and physical properties of the product meet the requirements.

- Sampling inspection:Take product samples from the injection molding production line and conduct inspections on size, appearance and physical properties to ensure that the quality of the product meets standard requirements.

- Defective product management:Establish a strict defective product management system to classify, record and handle unqualified products to ensure that defective products will not flow into the market or affect the normal operation of the production line.

Why Choose Longsheng for Injection Molding Services?

At Longsheng, whether you need prototype parts manufacturing or mass production, we have the corresponding capabilities and experience to meet your needs. We are committed to providing reliable, quality parts to assist you with success in the competitive automotive market.

Rapid quotation:Just upload the CAD file, you can quickly understand the manufacturing cost and keep abreast of the order status.

Quick molding:Longsheng has extensive experience in prototype manufacturing, ensuring that your components are completed with high quality in the later stages of the design and manufacturing process.

ISO attestation:Longsheng is a ISO 9001 certified manufacturing company, which means that we employ internationally recognized best practices to develop your products and ensure that they meet the standards, regardless of the complexity of the design.

Customized on demand:Our auto parts manufacturing process is fully customizable according to your specifications, sizes, materials and surface requirements to ensure meeting your unique needs.

Express delivery:We are committed to providing, fast manufacturing and delivery to meet your production needs while providing you with greater flexibility to quickly respond quickly to market changes.Longsheng is a partner of your auto parts needs.

FAQs

1.What are the main types of plastic used in injection molding?

Plastics used in injection molding are mainly divided into two categories: thermoplastics and thermoset plastics. Thermoplastics include but are not limited to polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polycarbonate (PC), polyamide (PA), polyethylene terephthalate (PET) ; Thermosetting plastics include but are not limited to polyurethane (PU).

2.How do you design a mold for injection molding?

Whendesigning an injection mold, multiple factors need to be considered to ensure that the core-pulling slider mechanism is minimized and the impact of the parting line on the appearance is eliminated. When designing the product structure, structures such as reinforcing ribs, buckles, and protrusions should be consistent with the direction of mold opening to avoid core pulling, reduce seam lines, and extend the life of the mold; set an appropriate demoulding slope to avoid product nap or top damage; deep When designing products with cavity structures, the slope of the outer surface should be greater than the slope of the inner surface as much as possible to ensure that the mold core does not deflect during injection molding. Plastics have a certain wall thickness range, generally 0.5~4mm. When the wall thickness exceeds 4mm, it will cause problems such as long cooling time and shrinkage.

3.What are common defects in injection molding and how can they be avoided?

Common defects in injection molding and methods to avoid them mainly include ① Underfilling. In order to avoid the defect of underfilling, the injection speed should be increased, the amount of plastic in the hopper should be checked, and the injection stroke should be checked correctly. ② Weight and size changes. In order to avoid defects caused by weight and size changes, it is necessary to check whether there is sufficient cooling water flowing through the hopper throat to maintain the correct temperature, check the injection volume and plasticizing capacity of the injection molding machine, etc. ③ Burning can be avoided by lowering the temperature of the first two areas of the injection cylinder, reducing the injection speed, etc. ④Cracks can be avoided by using multi-point distribution point gates, side gates and handle gates; appropriately increase the resin temperature to reduce the melt viscosity; increase the mold temperature; appropriately shorten the injection and holding time, etc.

4.What factors affect the cost of injection molding?

There are many factors that affectinjection molding costs, including mold costs, material costs, product structural complexity, production quantity, production efficiency, equipment usage costs, labor costs, secondary processing costs, logistics costs, etc. Injection molding costs are affected by many factors. The influence of factors requires comprehensive consideration and optimization in all aspects of design, production, management, etc. to reduce costs.

Summary

Key design considerations for injection molding include mold design, wall thickness, gate construction, part ejection and draft angles, as well as tolerances and shrinkage.Injection molding faces many challengesincluding flow analysis and simulation, cooling and cycle time optimization, avoiding common defects, and quality control. These factors are interrelated and jointly affect the quality and production efficiency of injection molded products. By carefully evaluating and optimizing these parameters, you can ensure that theinjection molding process is stable and reliable, producing high-quality plastic products that meet design requirements.

Disclaimer

The content on this page is for reference only.Longshengdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

Longsheng Team

This article was written by multiple Longsheng contributors. Longsheng is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.