As an important industrial material,silicone is widely used in many fieldswith its unique physical and chemical properties. According to the nature, composition and application characteristics, silicone can be divided into many types. Next, we will introduce thefour common types of siliconeand their differences.

What are the 4 types of silicone?

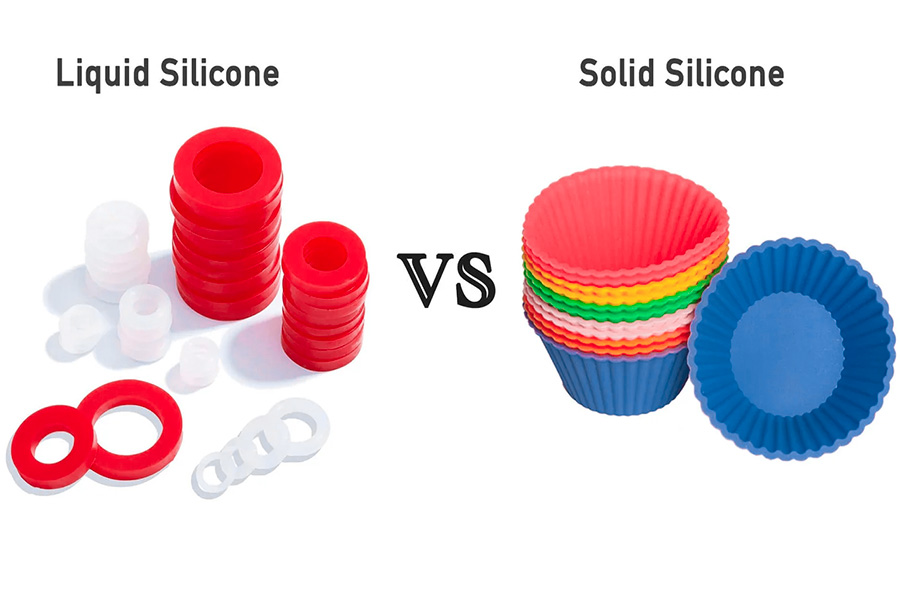

1.Liquid Silicone Rubber (LSR)

Liquid silicone rubber is a two-component platinum-curable elastomer with low viscosity, good flowability and fast curing at high temperatures. Its durability and flexibility, as well as its resistance to extreme temperatures, chemicals, and UV radiation, make it a popular choice for sophisticated, complex design applications.

- High temperature resistance:Liquid silicone rubber can maintain its own structural integrity in extreme high and low temperature environments, showing excellent heat resistance and stability.

- Mechanical properties:Its long polymer chain and elastomer properties give it good flexibility and elasticity, and excellent mechanical properties.

- Electrical barrier:It has inherently electrically insulating properties and performs well in electronic applications where dielectric strength is required.

- Chemical resistance:Resistant to a wide range of chemicals, oils and water, and can be used in harsh environments.

Biocompatible: Commonly used in medical devices, it is biocompatible and safe in applications involving human contact.

2.High Consistency Rubber (HCR)

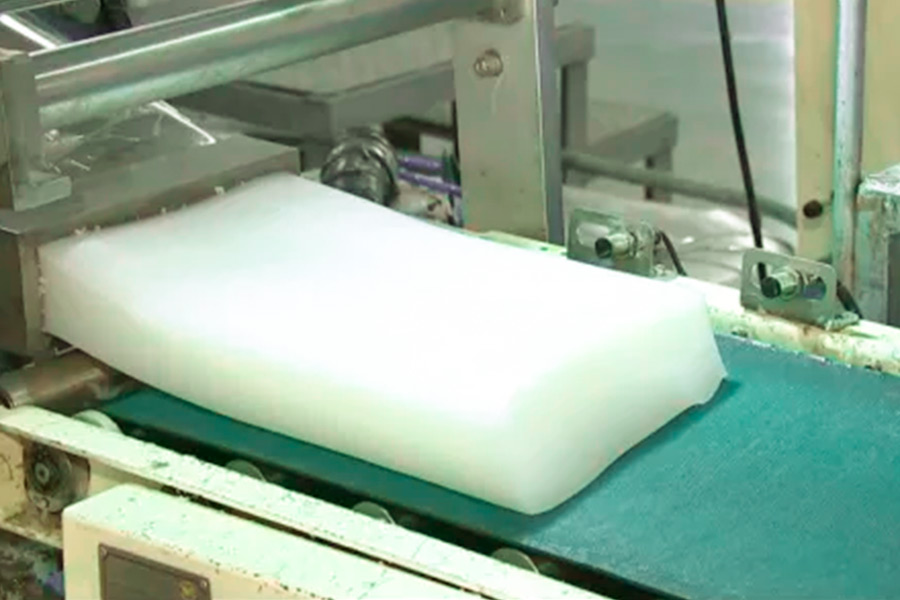

High-consistency silicone rubber, also known as "solid silicone" or "rubber", consists of a high molecular weight polysiloxane chain that can be filled with a variety of fillers to optimize hardness, heat resistance, and more. It can be cured by a peroxide curing system or a platinum catalyst formulation without chemical by-products. HCRs are typically supplied in bulk form such as rods, tubes, cylinders, etc., for easy subsequent processing.It is a high-quality material for long-lasting implantable medical devices,automotive engine components, and numerous household consumer products, and excels in applications that require durability and structural integrity, with excellent mechanical properties, high tensile strength, and abrasion resistance.

- Heat Resistance:HCR is extremely heat-resistant and maintains integrity even at extreme temperatures after being cured at high temperatures.

Mechanical durability: Long polymer chains and high molecular weight determine its physical and mechanical properties, with high tensile strength and durability. - Chemical stability:Pure silicone rubber matrix contains methyl and vinyl groups, combined with silicone oils and greases, making solid silicone rubber inherently chemical and weather resistant, and practical under harsh conditions.

- Versatility and adaptability:HCRs can be blended with a variety of additives, such as more silicone oils and greases, to tailor properties to specific application needs, from enhanced elasticity to improved chemical resistance.

3.Room temperature vulcanized (RTV) silicone

Room-temperature vulcanized silicone cures without heat and is available in both one-component (RTV-1) and two-component (RTV-2) types. RTV-1 is easy to use, making it an ideal material for sealants, adhesives and coatings; RTV-2 is used in a mix and is commonly used in 3D printing, surface coating, and molding. Both types have excellent thermal resistance and mechanical properties. Room temperature vulcanized silicone is a one- or two-component material that cures at room temperature to form a flexible and durable rubber with good adhesion, electrical insulation, and good resistance to moisture, chemicals, and extreme temperatures.

- Easy to use:Spreads and cures at room temperature, providing convenience and productivity for sealing and molding applications.

Flexibility and durability: After curing,RTV silicone has excellent flexibility and durability, can adapt to various environmental conditions, and is not easy to degrade. - Chemical resistance:It is chemically resistant to a wide range of substances and is suitable for applications where it is exposed to harsh chemicals for a long time.

- Thermal stability:In a wide range of temperatures from low temperature to medium and high temperature, it can maintain its own physical characteristics, and has high reliability in different environments.

4.Fluorosilicone Rubber (FSR)

Fluorosilicone rubber (FSR) is a unique elastomer that combines the properties of both silicone and fluorocarbon materials. FSR has excellent resistance to fuels, oils, solvents and extreme temperatures while retaining the flexibility and elasticity of standard silicone rubber.

Features:

- Chemical resistance:Provides excellent resistance to aggressive chemicals and oils.

- Temperature stability:Maintains properties under extreme temperatures.

- Durability:Molecular structure is strong and polymer chains are relatively long.

- Versatility:Available in both liquid and solid silicone rubber forms, suitable for a wide range of silicone rubber products.

Which Industries Use Each Type?

- LSR is commonly used in medical devices, automotive components, consumer goods, and electronics, among others. Some typical applications include seals, gaskets, baby bottle nipples, and overmolded parts for electronics.

LSR allows us to precisely produce complex designs, ensuring our custom products meet the highest quality standards while providing optimal functionality and durability. - HCR is commonly used in gaskets, seals, O-rings and shock absorbers in the automotive, aerospace, construction and consumer goods industries.

By incorporating HCR into our products, we ensure improved performance, service life and wear resistance to meet the diverse needs of our customers. - RTV silicone is frequently used for sealing, bonding, potting and encapsulation in various industries such as electronics, automotive, aerospace and construction.

LS utilizes the excellent bonding and sealing properties of RTV silicone to manufacture custom silicone products that require bonding or sealing, ensuring reliable, long-lasting connections between components. - FSR is widely used in seals, gaskets and O-rings in the automotive, aerospace, and oil and gas industries, where they may be exposed to aggressive chemicals and extreme conditions.

What are the differences between the 4 types of silicone?

In order to grasp the unique capabilities of each silicone variant, it is essential to compare them side by side.

| Feature | LSR | HCR | RTV | Fluorosilicone |

|---|---|---|---|---|

| Cure System | Platinum catalyzed cure system | Peroxide/Platinum catalyzed | Condensation cure system | Platinum catalyzed cure system |

| Consistency | Liquid, heat curable elastomer | Solid, heat cured elastomer | Varies, room temperature vulcanization | Solid or liquid, heat curable elastomer |

| Temperature Resistance | High temperatures | High temperatures | Moderate to high temperatures | High temperatures |

| Chemical Resistance | Good, with excellent resistance | Good, with excellent resistance | Good, with excellent resistance | Excellent, with excellent resistance |

| Primary Applications | Sealing applications, silicone products | Sealing applications, silicone products | Sealing applications, silicone products | Sealing applications, silicone products |

| Mechanical Properties | Flexible, with relatively long polymer chains | Durable, with relatively long polymer chains | Flexible, varies with formulation | Durable, with relatively long polymer chains |

| Raw Materials | Silicone polymers, methyl groups | Silicone polymers, methyl groups | Silicone polymers, methyl groups | Silicone polymers, methyl and phenyl groups |

What are the forms of silicone?

- Emulsion: composed of silicone molecules, used as lubricants, release agents, cleaning andpolishingagents.

- Oil: linear polysiloxane chains, which act as lubricants and can be used as hydraulic oils, lubricants and processingraw materials.

- Liquid: Liquid silicone rubber has good fluidity and is used for precision injection molding, such as gaskets, electronic potting, etc.

- Sealing agent: viscous room temperature vulcanized silicone, good processability, strong adhesion and durability.

- Resin: thermosetting product, used for adhesives, protective waterproof coatings and heat-resistant coatings.

- Grease (silicone grease): made of silicone oil plus filler, lubrication, heat conduction, corrosion protection, used as release agent, sealant, etc.

- Gel: two-component platinum-catalyzed liquid formula, used for medical scar reduction.

- Foam: made of liquid silicone plus degassing agent, different densities, used for gaskets, caulking agents, etc.

- Solid: long polymer chainsilicone rubber, dense and hard, used for pipes, seals, etc.

Summary

It is essential to be familiar with the properties of various silicones, including low-strength silicone rubber (LSR), high-consistency silicone rubber (HCR), room temperature vulcanized (RTV) silicones, and fluorosilicone, which is crucial for making wise choices in various industries.

Whether choosing silicone sealants in the construction field, heat-cured elastomers in automotive parts, or silicone polymers required for medical devices, it is crucial to understand the unique properties of each silicone material and its applicable scenarios.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyspecializing in custom manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precisionCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 advanced 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries worldwide. Whether it’s low-volume production or large-scale customization, we can meet your needs with delivery as fast as 24 hours. ChoosingLS Technologymeans choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.What is the difference between silicon and silicone?

Silicon, as a naturally occurring chemical element, is extremely abundant in the earth's crust, second only to oxygen. It has both metal and non-metal properties, and this unique property makes it play a key role in many industrial fields. In the electronics industry, silicon is the core material for manufacturing semiconductors and has made an indelible contribution to the development of modern electronic technology; in the construction field, it is used to produce various building materials; in the photovoltaic industry, silicon is an important component of solar panels.

Silicone is a synthetic polymer whose constituent elements include carbon, hydrogen, etc. in addition to silicon and oxygen. The common form of silicone is soft texture or liquid, with excellent electrical insulation, heat resistance and adsorption capacity. These properties make silicone very useful in many fields. In the medical field, it can be used as an implant material; it can also be found in personal care products; in kitchen supplies, such as oven gloves, silicone is used; in the electronics field, it can be used to make protective covers for electronic components, etc.

Simply put, silicon is an element that exists in nature, and silicone is a synthetic material made based on silicon. The two are significantly different in properties, appearance, and use.

2.How do I choose the right silicone for my application?

When selecting the right silicone for your application, you need to consider a variety of factors, including the type of material, the environmental conditions in which it is located, and the performance requirements. For example, acetoxy silicone is commonly used in general sealing scenarios, but it can cause corrosion to some sensitive materials. In contrast, neutral-curing silicones are more suitable for electronics and metal-related applications because they are not corrosive.

According to the actual needs of the project, it is necessary to evaluate the performance of silica gel in different temperature environments, as well as its resistance to ultraviolet rays and chemicals. At the same time, ensure that the silicone has good compatibility with the substrate it is in contact with, so that the best bonding effect can be achieved. In addition, the curing time, the ease of use, and the availability of relevant safety certifications should not be overlooked. Referring to the manufacturer's guidelines, and seeking technical support if necessary, can help you select the right silicone product for your specific project.

3.Is silicone a plastic?

Silica gel is not a plastic, it is a polymer material synthesized from silicon, oxygen and other elements through a specific process. Silicone has many unique properties, such as heat resistance, oil resistance, chemical resistance, and environmental protection, non-toxic and odorless, and can be easily processed into products of various shapes and sizes.

Compared with plastics with resin as the main component, silicone has obvious differences in performance, use and environmental performance. Plastics are generally added with plasticizers, fillers and other additives, which may cause some pollution to the environment after use. Silicone, on the other hand, is a relatively more environmentally friendly material, which has been widely used in many fields such as medical treatment, electronics, automobiles, and food packaging. So, silicone and plastic are two very different materials.