Yangchun March, the world-famous industry event,the 2025 GLOBAL INDUSTRIE Gala, opened in Lyon, France. As a leader in innovation in the industry,LS Companyis honored to be invited to the exhibition and will showcase the exciting exploration of the future of industry in booth 6N147 at Pavilion 6.

Basic information of the exhibition

- Name of the Exhibition: GLOBAL INDUSTRIE 2025 (French International Industrial Fair/Paris International Industrial Parts Exhibition)

- Dates: March 11 to March 14, 2025

- Venue: Exhibition Centre, Lyon, France

- Duration: Once a year

- Moderator: GL Group, France

- Exhibition area: Expected to reach 100000 square meters

- Exhibitor: 2400 companies are expected to attend.

- Professional audience: Expect 40000 to 50000 professional audiences

GLOBAL INDUSTRIE Exhibition Features and Highlights

1.Integration of four/five major sectors:This exhibition combines four/five industries MIDEST, SMART-INDUSTRIES, INDUSTRIE Paris, TOLEXPO to form a brand new exhibition. These segments represent different industry areas and specialties and provide comprehensive industry solutions for exhibitors and visitors.

2.Wide range of exhibits: Exhibits range frommetalworking, molds,electronicsand industrial maintenance. It also includes cutting-edge technologies and products such as digital industry chains, internal logistics and automation.

3.Strong professionalism:The exhibitionfocuses on the field of industry, for exhibitors and visitors to provide a professional and efficient communication platform. During the exhibition, a number of technical lectures and exchanges will be held to promote technological innovation and industrial upgrading.

4.High degree of internationalization: The exhibition attracts exhibitors and visitors from all over the world and provides an important platform for international industry cooperation and exchange.

LS Company Introduction

As a leading company specializing in onlineCNC machining,sheet metal processing,3D printingandprototype production services,LShas been dedicated to promoting innovation and development of industrial manufacturing technology. Our business covers everything from design to production, providing customers with one-stop, customizable solutions. At the GLOBAL INDUSTRIE 2025 exhibition, we will showcase our full range of business, including but not limited to precision machining, sheet metal processing, 3D printing technology, prototype production, and subsequent assembly and testing services.

The core advantages of LS enterprise

1.Technology integration capability

- We can offer bothCNC precision machiningand3D printing (additive manufacturing)to meet a wide range of needs from rapid prototyping to mass production.

- Technical compatibility: Supports flexible switching betweenmultiple materials (metal/plastic/composite)and multiple processes (SLA/DLP/FDM/metal 3D printing).

2.Rapid response and delivery

- Digital processing shortens the design iteration cycle and allows 24-hour sampling or emergency order processing.

- Global supply chain or localized production networks to ensure efficient implementation of cross-border projects.

3. High precision and complex structure

- CNC machine tools high precision (micrometer level processing)with complex geometric freedom of 3D printing and are suitable for high-end fields such as medical equipment and aerospace.

- Surface treatment and quality inspection techniques (such as CT scanning, CMM measurement) ensure product consistency.

3.Customized services and cost optimization

- On-demand production model reduces inventory costs and supports small batch customization (as low as 1 MOQ).

- Parameterized design tools or AI-assisted optimization can reduce material waste and improve productivity.

4. Industry experience and case accumulation

- Deep-ploughed specialty industries (e.g.Car,consumer electronics,medical health, etc.), accumulating patented technologies or industry certifications (ISO 9001, ISO 14001).

-

Case sharing

Project Background: A leading automobile manufacturer needs to manufacture precisely designed components for new models of electric vehicles.

Challenge: The components required must meet stringent quality standards and deadlines while remaining cost-effective.

Solution: We utilize advanced processing ability and efficient production process to providehigh-precision CNC milling parts.

Results: The project was completed ahead of schedule, the parts met all quality and performance requirements, and the new car was successfully launched.

LS' diversified services and achievement display

LS company will launch a range of quality products that represent the company's technological prowess and innovation capabilities. These products not only demonstrate our superior capabilities in material selection, process optimization, and quality control, but also reflect our deep insight into customer needs and market trends. We can provide high quality products to meet our customers' needs, whether it'sprototype production car parts, prototyping medical devices or prototyping consumer electronics products.

1.CNC machining:LS provides professionalCNC machining servicesandproduces custom partswith a precision tolerances up to 0.005 millimeters. Our capabilities cover a wide range of materials, including metals and plastics, to meet the needs of different industries. Whether yourproject is small or large, LS is committed to providing efficient and cost-effective NC machining services from design to final production.

CNC machining results display:

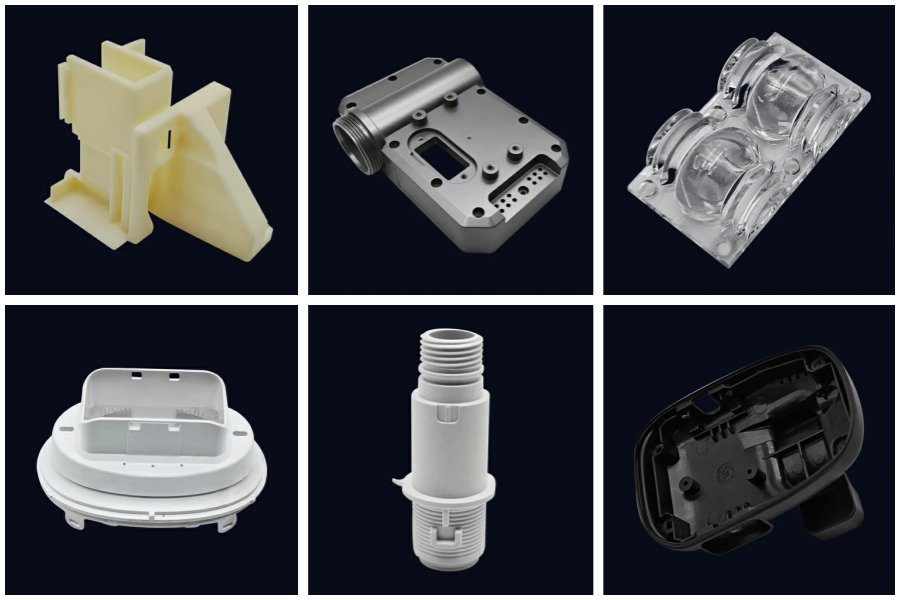

2.Injection molding: LS provides industry-leading injection molding services with a wide range of technologies and materials for a variety of industrial applications. With ISO 9001:2015 certification, our advanced mechanics and experienced engineers ensure that every part of our production meets the highest standards of quality, accuracy and repeatability.

Injection molding results display:

3.Metal casting:We provide high quality metal casting services and robust, accurate and economical solutions for complex metal components. We are able to handle a wide range of materials, including aluminum, steel and other alloys, while maintaining strict tolerances and excellent surface finish.

Metal casting results display:

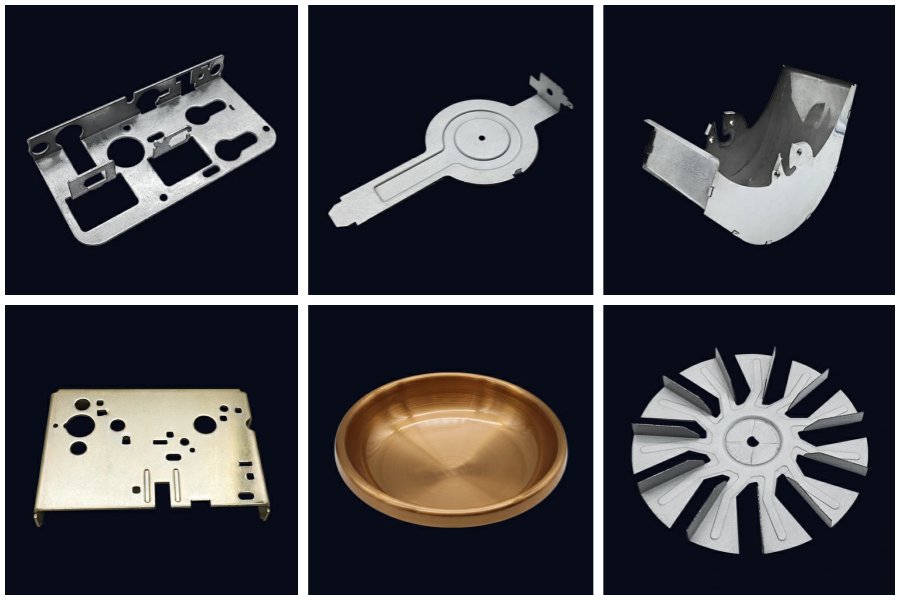

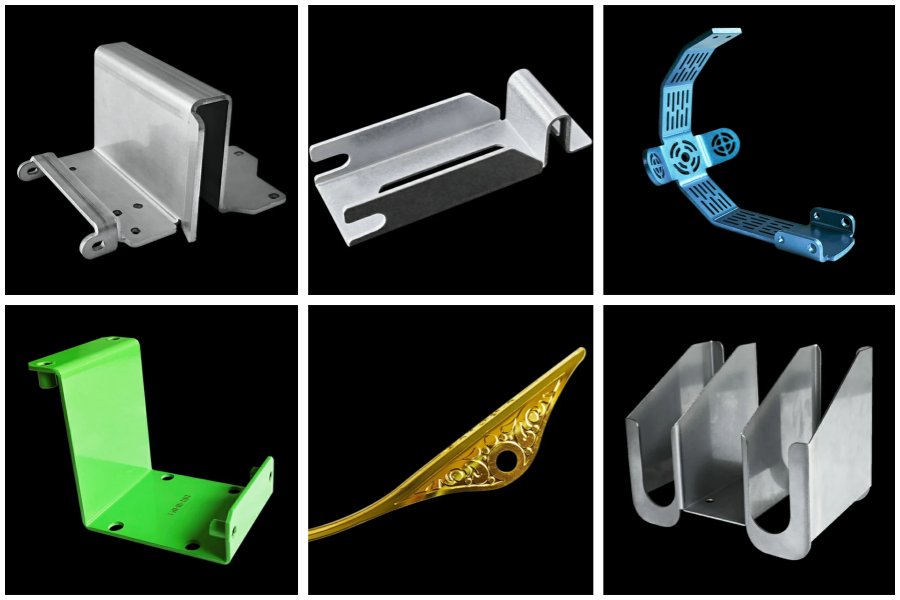

4. Sheet metal processing:At LS, we providehigh precision sheet metal manufacturing servicesand customized solutions for industries that require complex design and durable metal components. Our sheet metal manufacturing process ensures precision cutting, bending and assembly, producing parts with excellent accuracy and structural integrity.

Sheet metal processing results show:

5.3d Printing:LS provides innovative solutions forrapid prototyping design and custom component production. Through the the ISO 9001: 2015 certification process we utilize advanced additive manufacturing techniques to create complex geometric shapes and designs with high precision. This method can be applied to plastics, metals, composites and other materials, and can be used to produce lightweight and efficient components.

3D-printed results display:

The core reason for choosing LS

1.Rapid response and customization capabilities

- Agile delivery: Reduce prototype development to four weeks of production cycle (traditional model takes several months) to meet urgent project requirements.

- On-demand production model:Support small batch(as low as 1 piece) customization to reduce inventory costs.

- Interdisciplinary technology adaptation: Metal casting, CNC machining, 3D printing, multi-process collaboration to address complex requirements of a wide range of materials and scenarios.

2.Innovative Engineering Solutions

Our experienced engineering team works closely with you to develop innovative solutions that meet your specific needs. We utilize the latest technology and methods to ensure optimal performance and cost-effectiveness.

3.Global Service Network

We have factories and partners around the world serving customers around the world. Our global network ensures that we can deliver your products wherever you go while maintaining the same quality

4.Reputation

PossessingISO 9001 (quality), ISO 14001 (environment)international certification and other authoritative qualifications.

Exhibition on-site experience area

1.Digital sand table simulation:Visitors can use AR glasses to manipulate the virtual factory and observe the optimization path of the intelligent decision-making system in real time.

2.Rapid prototyping workshop:On-site3D printing service(output of custom keychain or badge models within 1 hour).

3.Technical Expert Q&A Desk:Assigned engineering team to interpret the technical white paper and provide 1v1 solution consultation.

Exhibition benefits are being broadcasted, not to be missed

During the exhibition, LS will offer customers who sign up on-site a specially tailored package that includes, but is not limited to, price discounts, renewal services, customized solutions and more to help you embrace the future of industry at a more favorable price. For LS VIP customers, we will alsoarrange a one-on-one exclusive reception servicesto ensure a more efficient and enjoyable visit with in-depth technical exchanges, live presentations, future cooperation planning and more.

Gather in Lyon and create brilliance together

Spring is in the air in Lyon in March, and the stage is set for GLOBAL INDUSTRIE 2025. LS Company looks forward to meeting you at booth 6N147 in Pavilion 6 on our wonderful journey to explore the innovative future of the industry. Here, you can not only experience the most cutting-edge scientific and technological achievements, but also interact with industry elites in depth, collide for more inspiration. Let us join hands to create a better future for the industrial age!

Exhibition guide, visitor guide

- Registration and admission:Visitors are required to register on exhibition website or on thesite in advance to obtain admission credentials before entering the exhibition area.

- Transport guide:Lyon Exhibition Center Exhibition Centre is well located and accessible by public transport (e.g. metro, bus) or self-drive. It is recommended to check transportation routes and timetables in advance to avoid delays.

- Visit plan:the exhibition is large and abundant of exhibits. The company is located in booth 6N147, Pavilion 6. We recommend that you know the location of the booth in advance so you can visit and communicate more effectively.

- Language support:The booth offers information packages in English, French and German.

- Contact: LS Hardware Tech Co., Ltd, info@longshengmfg.com.