In the ever-evolving landscape of manufacturing and design, the demand for precision and flexibility in material cutting has surged. This is where **laser cutting services** come into play, revolutionizing how industries approach fabrication and design tasks. Laser cutting technology offers unprecedented precision, allowing manufacturers to create intricate designs with ease, supporting a wide range of applications, from industrial projects to customized solutions, making it an indispensable tool in modern manufacturing.

Laser cutting services utilize advanced laser cutting technology to tailor solutions that meet the varying needs of numerous industries. These services excel in delivering high precision cuts with minimal waste, irrespective of the complexity or material. The laser cutting process involves directing a high-powered laser beam onto the material, which then melts, burns, or vaporizes away, leaving a precise edge. This process is enhanced by computer numerical control (CNC) systems that guide the laser with unmatched accuracy, guaranteeing quality across every cut.

With the advent of fiber laser cutting and CO2 laser cutting, laser cutting services have expanded their capabilities. Fiber laser cutting, known for its speed and efficiency, is well-suited for metal cutting, providing rapid and precise results. CO2 laser cutting, on the other hand, offers versatility with a wider range of cutting applications across different materials such as wood, plastics, and even fabrics. Together, these technologies allow laser cutting services to cater to specialized needs, whether it is in industrial laser cutting or custom laser cutting.

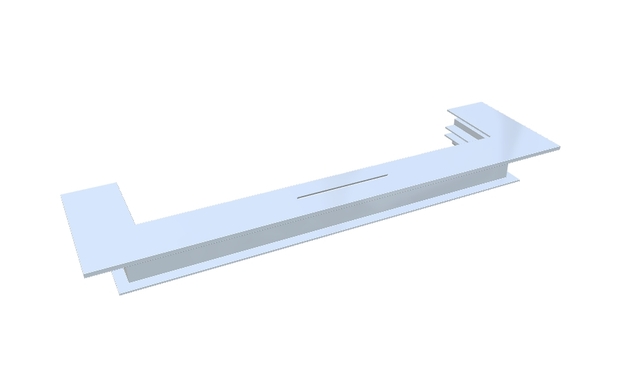

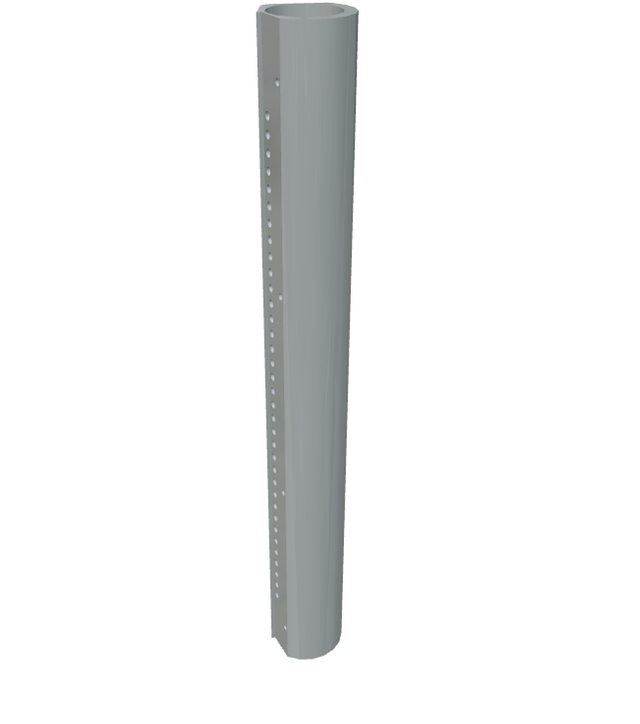

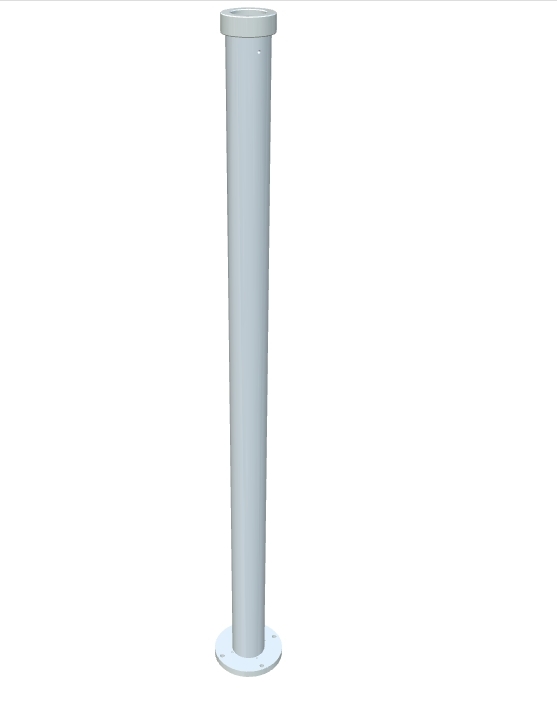

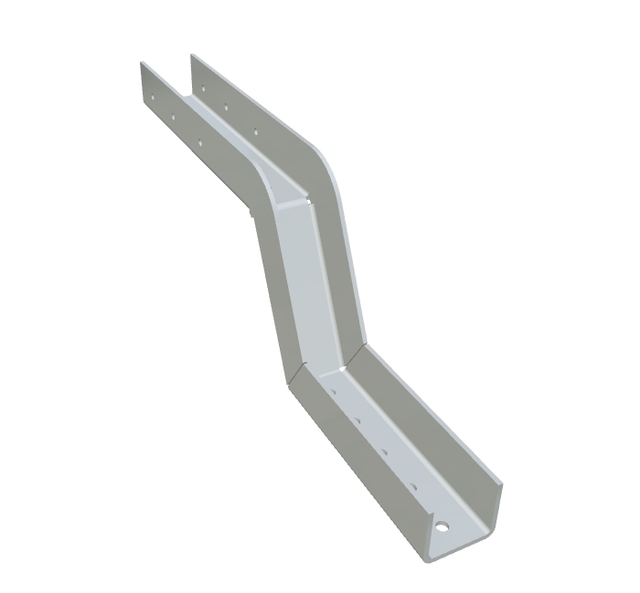

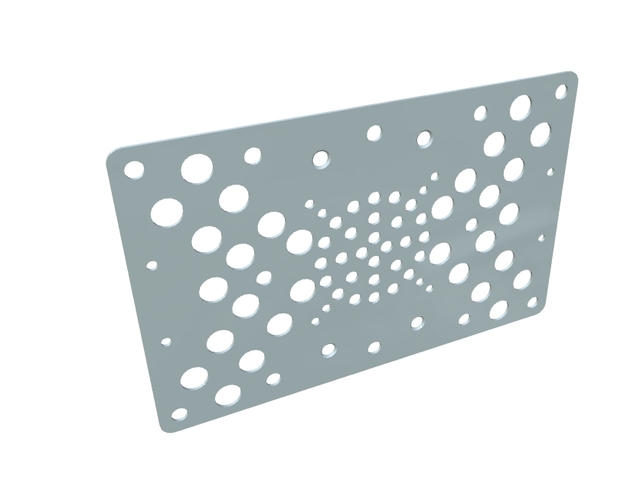

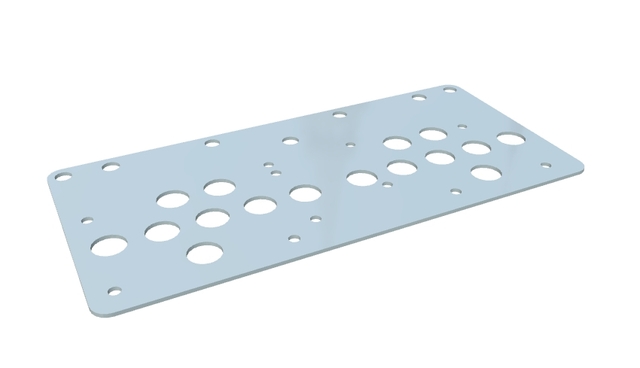

The versatility of laser cutting services is further demonstrated in the variety of materials they can work with. From metals to plastics, the adaptability of laser cutting technology ensures that almost any design can be brought to life. This flexibility makes it an ideal choice for producing components that require distinct shapes and features, such as the innovative Perforated Metal Mounting Plate.

The Perforated Metal Mounting Plate epitomizes modern engineering excellence by harnessing the power of laser cutting. Designed for ultimate efficiency and style, this versatile mounting solution is crafted from high-grade, corrosion-resistant materials. Its robust construction is enhanced by an array of meticulously placed circular perforations that allow for enhanced flexibility in mounting and securing various components. The varying sizes of these holes accommodate a wide range of fasteners and fittings, marking it as a perfect fit for any custom project.

Incorporating the smooth, rounded edges typical of products produced via precision laser cutting, the Perforated Metal Mounting Plate ensures safety in handling and ease in application. This non-compromising strength and lightweight nature allow it to seamlessly integrate into diverse applications such as construction, cabinetry, and even artistic installations. The strategic placement of holes facilitates optimal support distribution, effectively reducing strain on any single point, highlighting its intelligent design suited for both creativity and functionality.

Laser cutting manufacturers continually innovate to offer cutting-edge solutions. By providing state-of-the-art laser cutting machines for sale, businesses can bring the capabilities of precision laser cutting in-house, potentially reducing costs and lead times for projects. The continuous improvements in laser cutting machine technology are testament to the rising demand for efficient, precise, and cost-effective cutting solutions.

The applications for laser cutting are seemingly endless. From the automotive industry to aerospace, electronics to the arts, the ability to produce both high-quality prototypes and large-scale production runs makes laser cutting services indispensable. Laser cutting design facilitates the crafting of complex geometries that would be difficult, if not impossible, to achieve using traditional methods. It supports projects that demand tight tolerances and uniformity across intricate components.

In summary, laser cutting services provide the foundation for a myriad of industrial and creative applications by combining high precision, speed, and versatility. As industries continue to require smarter, more effective solutions, laser cutting manufacturers will undoubtedly play a crucial role in meeting these challenges. The seamless integration of modern design with the capabilities of laser cutting technology, as seen in products like the Perforated Metal Mounting Plate, exemplifies this technological synergy that continues to push boundaries in manufacturing excellence.

Laser Cutting Services: Innovating Precision & Versatility

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.