CNC milling is revolutionizing the way we approach precision engineering and manufacturing. As a mainstay in the machining industry, CNC milling allows manufacturers to produce intricate and precise parts with unparalleled accuracy. With advancements such as 5 axis CNC milling, the capabilities of these machines have been significantly enhanced, opening new avenues for complex part fabrication. Whether you're utilizing small CNC milling for compact components or seeking a comprehensive CNC milling service for larger projects, understanding the nuances of this technology is essential.

The complexity and precision afforded by CNC milling machining make it a treasured asset across numerous sectors. One of the key advantages of CNC milling is its versatility. It can cater to both small-scale operations and large ones, while still providing the exactness needed for each. This dual capacity can highly optimize production cycles, ensuring efficiency regardless of the project scale. The economic implications are notable too, as CNC milling machine costs have become more accessible, expanding the technology's availability to more manufacturing entities.

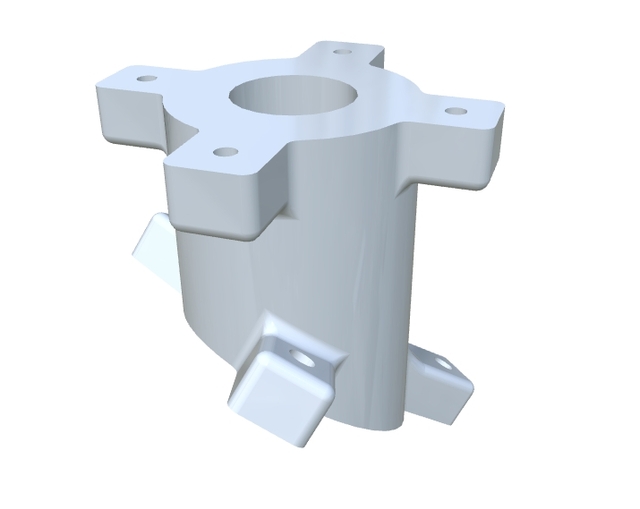

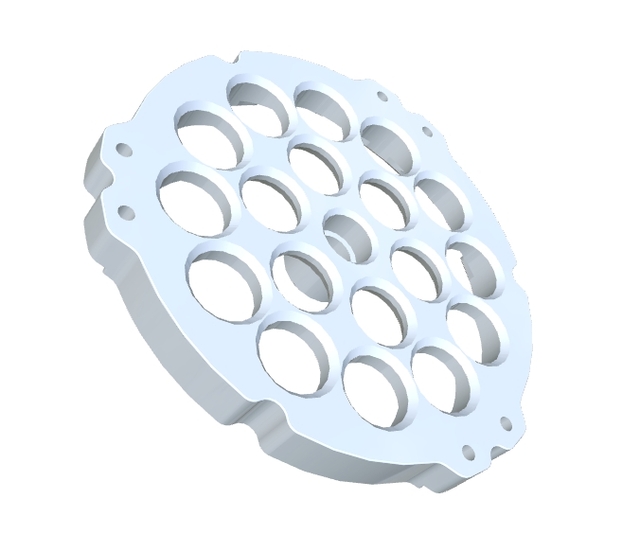

The cutting-edge nature of technologies such as 5 axis CNC milling allows for a seamless integration of intricate designs, particularly those that demand detailed curvature and precise machining. This is where our latest innovation in structural design, the Eco-Frame Enclosure, becomes highly relevant. Crafting this product requires exceptional precision, a feature well-managed by CNC milling. The enclosure exemplifies sustainable construction, made from eco-friendly materials and designed for optimal airflow. It's the perfect embodiment of functionality meeting environmental responsibility, which aligns with the precise outputs that CNC milling delivers.

As an industry leader, the protection of sensitive electronic components is a priority, and the Eco-Frame Enclosure showcases how CNC milling can provide robust and stylish solutions. The design features meticulously molded edges and corners, an achievement made possible by the precision of CNC milling turning. This product is ideal for both DIY enthusiasts and seasoned professionals who demand reliability in their enclosures. By leveraging CNC milling techniques, we ensure both the structural integrity and aesthetic quality of our offerings.

In conclusion, CNC milling continues to evolve as a critical component of modern manufacturing. Its role in producing products like the Eco-Frame Enclosure demonstrates its ongoing relevance and importance. Whether you're calculating CNC milling machine costs or contracting CNC milling service for a significant production batch, the focus on precision, efficiency, and sustainability remains constant. As we continue to innovate within the field, the legacy of CNC milling as an indispensable manufacturing practice holds strong.

CNC Milling: Revolutionizing Precision with Eco-Frame Design

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

CNC Machining Services: Precision & Innovation

CNC Milling Machines: Precision in Engineering Applications

Revolutionize Manufacturing with CNC Milling Machine Precision

Innovative CNC Milling Services for Precision Parts

Maximizing Efficiency with CNC Milling Services

CNC Milling: Revolutionizing Manufacturing & Design

CNC Milling: Revolutionizing Precision Perforated Discs

CNC Milling: Revolutionizing Design with Precision and Innovation

CNC Milling: Revolutionizing Precision with Eco-Frame Design