In the vast starry sky of the machinery manufacturing industry, pinion machining is like a bright star. Although it is small, it emits a light that cannot be ignored. As a key component in the mechanical transmission system, pinion not only carry the important task of transmitting torque and rotational motion, but are also a concentrated expression of modern industrial precision manufacturing technology. Today, let the Longsheng team take you to discuss what is pinion machining?

What is Pinion Machining?

The meaning of pinion machining refers to using raw materials (usually metals, such as steel, cast iron, aluminum alloys, etc.) through a series of mechanical machining processes, such as cutting, grinding, rolling, etc., to accurately produce pinion gears that meet the design requirements. process. The pinion is an important part of the mechanical transmission system. It transmits torque and rotational motion through the meshing between teeth, and realizes the conversion and transmission of mechanical energy.

What are the types of pinion machining technologies?

Pinion machining technology mainly includes the following types, each type has its unique application scenarios and advantages:

1.Gear Hobbing

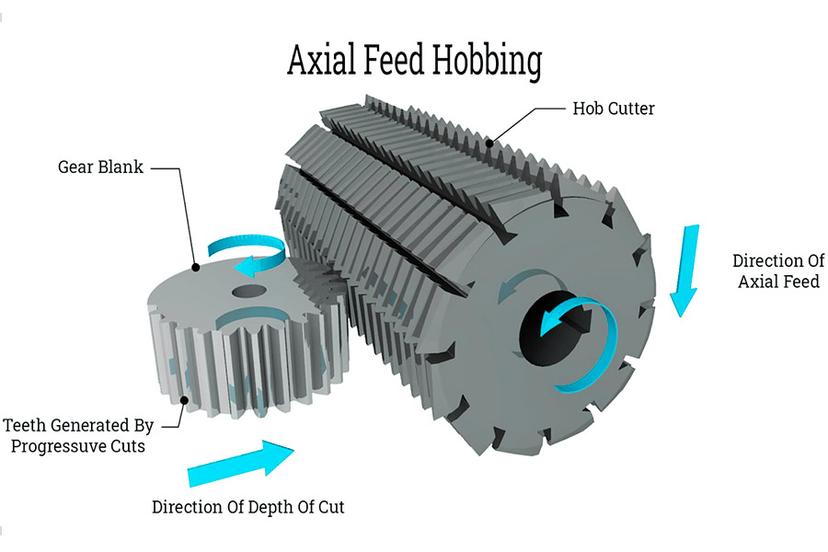

- Type:It belongs to the generation method machining, which uses the relative movement between the hob and the workpiece to form the tooth shape.

- Features:It is the most widely used technology in gear machining machine tools, especially suitable for batch gear production. It can process spur gears, helical gears, worm gears, sprockets, etc. The gear hobbing machine has high processing efficiency and relatively high processing accuracy, and can meet the needs of mass production.

2.Gear Shaping

- Type:It also belongs to the generation method, using a gear shaping cutter to process the tooth surfaces of internal and external gears or racks on a gear shaping machine.

- Features:Suitable for machining complex geometric shapes, such as internal gears, multi-link gears, etc. The gear shaping process is stable and can ensure the tooth shape accuracy and surface quality of the gear. At the same time, gear shaping processing can also form drum-shaped teeth to improve the position of the tooth surface contact area.

3.Milling

- Type:It belongs to forming method processing, using forming milling cutter to process gears by indexing method.

- Features:Suitable for small batch production and processing of special tooth shapes. Milling has high flexibility and can process gears of various shapes, but the processing efficiency and precision are relatively low. In addition, 5-section milling and 2-section hobbing are common cutting machining methods in micro gear machining.

4.EDM (Electrical Discharge Machining)

- Type:A non-traditional machining method that uses spark discharge to remove workpiece material.

- Features:Able to provide high-precision machining methods, especially suitable for machining hard materials and complex-shaped gears. No mechanical stress is generated during EDM processing, so problems such as gear deformation and cracks can be avoided. At the same time, EDM machining can also achieve micro-machining and mirror machining effects.

What are the advantages and disadvantages of pinion machining?

Pinion machining has significant advantages in improving transmission efficiency, extending service life, and improving product quality. However, it also has disadvantages such as high machining cost, high technical difficulty, and long machining cycle.

Advantages of pinion machining

- Improve transmission efficiency:Precision pinions can ensure efficient and smooth power transmission, reduce energy loss, and thereby improve the operating efficiency of the entire mechanical system.

- Extended service life:Through precision machining technology, the wear between gears can be significantly reduced, thereby extending the service life of the gears and the entire mechanical equipment.

- Improve product quality:Precision machining can ensure a high degree of consistency in gear size, shape, surface roughness and other parameters, thereby improving the overall quality of the product.

- Adapt to complex environments:Pinion machining technology can meet the requirements for gear performance under different working conditions. Whether it is high temperature, high pressure or highly corrosive environment, it can maintain good working condition.

- Diversified machining methods:There are various processing methods for small gears, such as gear hobbing, gear shaping, gear shaving, etc. Each method has its own characteristics and scope of application. The appropriate machining method can be selected according to specific needs.

- High-precision machining:In modern pinion machining, CNC technology is often used to precisely control the machining process through computers to ensure that each pinion can meet the accuracy required by the design.

Disadvantages of pinion machining

- High machining costs:The machining of precision pinions requires high-precision equipment and processes, which usually means higher processing costs.

- High technical difficulty:The machining precision of pinion gears is high, requiring experienced technicians to operate and monitor, and the technical difficulty is high.

- Long machining cycle:Due to the need for high-precision machining and inspection, the machining cycle of pinion gears is usually long, which may affect production efficiency and delivery time.

- Material restrictions:The processing of pinions has certain restrictions on material selection. It is necessary to choose materials with high strength and good wear resistance, which may increase the cost of raw materials.

- Errors and defects:Although modern processing technology is quite mature, errors and defects may still occur during the actual processing process, such as inaccuracies in tooth shape, transmission smoothness errors, etc., which may affect the transmission performance and life of the gear.

How does pinion machining work step by step?

Pinion machining is a complex and delicate process that often involves multiple steps and processes. The following are the general steps and working principles of pinion machining:

| Processes | Description |

| Material preparation | Select raw materials that meet the design requirements and perform necessary preprocessing, such as cutting into appropriate shapes and sizes. |

| Rough machining | Processing raw materials into gear blanks close to the final shape and size through cutting, milling and other processes. |

| Tooth shape processing | Use special gear processing equipment, such as gear hobbing machines, gear shaping machines, etc., to accurately process the gear tooth shape. This step requires extremely high precision and stability to ensure gear meshing performance and transmission efficiency. |

| Heat treatment | In order to improve the hardness and wear resistance of gears, it is often necessary to perform heat treatment on processed gears, such as quenching and tempering. |

| Finishing | Perform further finishing on the heat-treated gear, such as tooth surface grinding, burr removal, etc., to improve the surface quality and accuracy of the gear. |

| Inspection and testing | Strict inspection and testing of the processed pinion gears, including dimensional measurement, shape and position error detection, surface roughness detection and transmission performance testing, etc., to ensure that it meets the design requirements and usage standards. |

What are the applications of pinion machining?

Pinion machining has a wide range of applications. The following are its specific applications in different fields:

1. Automobile industry

- Driveline:Pinion gears play a key role in automotive transmissions, differentials, and drivetrains. They help achieve a smooth transfer of speed and torque between the engine and wheels, ensuring the car operates efficiently in different road conditions.

- Steering:Many power steering systems use pinion gears to transfer power from the steering wheel to the steering rack, improving the driver's steering experience and handling.

2. Aerospace

High-precision gear component manufacturing: Pinion applications in aerospace require extremely high precision and reliability. They are widely used in key parts such as satellite antenna pointing, solar panel rotation, aircraft landing gear transmission, and engine fuel injection systems.

Special environmental adaptability: In the aerospace field, pinion gears need to withstand the test of special environments such as high temperature, high pressure, and high corrosiveness. Therefore, there are extremely high requirements for material selection, processing technology and surface treatment technology.

3. Industrial machinery

- Automated machinery:In automated production lines, pinions are widely used in various transmission mechanisms and actuators to ensure precise operation and efficient production of mechanical equipment.

- Heavy machinery:In the fields of heavy machinery such as metallurgy and mining, pinions also play an important role. They are used to drive various large-scale equipment and mechanisms to achieve heavy-load and high-speed transmission.

4. Robotics

- Transmission mechanism:In robotics, pinions are used to drive various joints and actuators of robots to achieve flexible movement and precise operation of the robot.

- Manipulator:In automated production lines and robotic workstations, manipulators usually require small gears to transmit power and achieve precise control.

FAQs

1.What is the purpose of a pinion?

The role of gears is crucial in the field of mechanical engineering and technology, mainly in transmitting power and rotational motion. Through two or more gears meshing with each other, the power and motion of one gear can be transmitted to another gear. Thus driving the work of the entire mechanical system. Through the combination of gears of different sizes, the rotation speed can be increased or decreased and the torque can be transformed. By designing the tooth shape and installation method of the gear, the direction of rotation can be changed. Gear transmission can achieve remote transmission of power through a combination of an intermediate shaft and multiple gears. Gear transmission has high transmission accuracy and can achieve precise speed ratio and position control. Through complex gear combinations and mechanism designs, a variety of complex motion forms can be realized, such as indexing motion, intermittent motion, etc.

2.What is a pinion in mechanical engineering?

In mechanical engineering, a gear is a widely used transmission element, consisting of two or more gear teeth meshing with each other. Each gear has a central axis, and the meshing between the gears is performed between the two central axes. of. There are many types of gears, including face gears, bevel gears, worm gears, spur gears, involute gears, arc gears, etc. Each gear has its specific application scenarios, advantages and disadvantages.

3.What is pinion in technology?

In the technical field, gears are equally used in a wide range of applications. Whether it is the transmission mechanism on the automated production line or the control system in precision machine tools, they are inseparable from the precise transmission of gears. In addition, with the development of science and technology, gear processing technology and materials are constantly updated to meet the needs of higher precision, higher efficiency and higher reliability.

4.What is the difference between a rack and pinion?

The difference between rack and pinion is mainly reflected in ①Application scenarios: Rack: usually used to convert rotational motion into linear motion, or vice versa. Since it is practically impossible to have an infinitely long rack, the rack and pinion are not used to transmit continuous motion, but are used to transmit reciprocating motion. For example, converting the rotation of a car steering wheel into lateral movement of the wheels. ②Meshing mode: The meshing between the rack and the pinion is line-surface meshing, that is, the tooth surface of the rack and the teeth of the pinion contact each other on a straight line. The meshing between pinions is face-to-face meshing, that is, the teeth of the two gears mesh with each other on the planes that contact each other.

Summary

Pinion machining is a highly technical and demanding process that requires craftsmen to have extensive professional knowledge and practical experience, as well as a deep understanding of material properties, processing technology and precision control. Through precise processing and strict quality control, high-quality, high-performance pinions can be produced, providing a strong guarantee for the stable operation of mechanical equipment.

Disclaimer

The content on this page is for reference only.Longshengdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

This article was written by multiple Longsheng contributors. Longsheng is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.