Today, with the rapid development of science and technology, the birth of every new technology heralds a leap in human society.3d printingtechnology, as an outstanding representative in the field of additive manufacturing, is leading profound changes in the manufacturing industry and even the entire society with its unique charm and unlimited potential. So, what exactly is 3D printing? Why is it so compelling? This article will take you to find out.

What is 3D Printing?

3D printing, the full name of three-dimensional printing or additive manufacturing technology, is a technology that builds three-dimensional entities by accumulating materials layer by layer. Different from traditional subtractive manufacturing (such as cutting) or equal material manufacturing (such as casting, forging),3dprintingstarts directly from the digital model and uses precision equipment under computer control to stack materials into the required form. Shape and size. This process requires no molds or tools, greatly increasing design freedom and manufacturing flexibility.

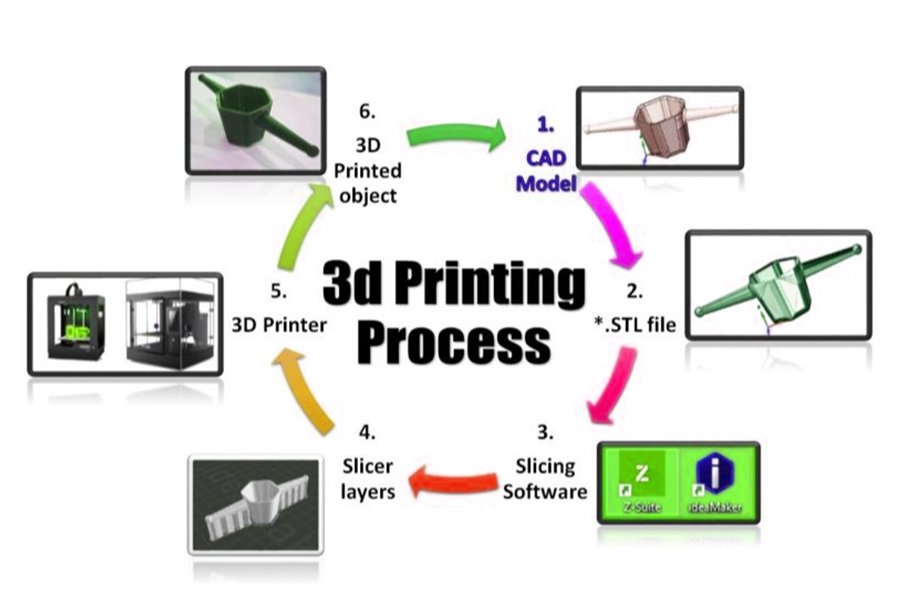

How Does 3D Printing Work?

1.Digital modeling

First, a digital3d models printingneeds to be created using computer-aided design (CAD) software or other 3D modeling software. These software enable users to design complex geometric shapes and create structures. After completion, users can export the3d printing modelsto 3D file formats such as STL and OBJ to facilitate subsequent processing in 3D printing software.

2.Data processing

Import the 3D model file into the 3D printing software, and the software will generate a series of slice information based on the model data. This slice information describes the shape and position of each layer in detail, providing guidance for the subsequent printing process. According to specific printing needs, users need to adjust printing parameters, such as layer height, printing speed, material temperature, etc., to ensure that the printed items meet the design requirements.

3.Printing process

Place the selected printing material (such as plastic, metal, ceramic, etc.) into the 3D printer. These materials are usually in powder, liquid or filament form and can be pre- or cured as desired. The 3D printer will heat,ink jet printingor extrude the material layer by layer based on the slice information, and display them together accurately. The process is similar to manual machining in traditional manufacturing, but 3D printing enables more complex structures and shapes. During the printing process, the 3D printer will control the temperature of the material according to default parameters to ensure printing quality and stability.

4.Post-processing

For some complex structures that require support, 3D printers will add additional brackets during the printing process. After printing, these brackets need to be removed. Since there may be some imperfections during the printing process, such as rough surfaces, gaps between layers, etc., the printed objects need to be trimmed and polished to improve their appearance and performance.

What are the advantages of 3D printing?

Compared to CNC machining, which uses subtractive manufacturing, additive manufacturing adds material in layers until the product is complete. There are many benefits to using 3D printers for both large businesses and individuals.

1.Manufacturing complex items does not increase costs

As far as traditional manufacturing is concerned, the more complex the shape of the object, the higher the manufacturing cost. With3d printing service, the cost of manufacturing complex-shaped items does not increase, and creating a gorgeous complex-shaped item takes no more time, skill, or cost than printing a simple square. Making complex items without increasing costs will upend traditional pricing models and change the way we calculate manufacturing costs.

2. Product diversification without increasing costs

3D printing can print a variety of shapes, making items of different shapes like a craftsman every time. Traditional manufacturing equipment has fewer features and is limited in the variety of shapes it can produce. Instead of training machinists or buying new equipment, 3D printing requires different digital design blueprints and a new batch of raw materials.

3.Zero-skill manufacturing

Traditional craftsmen require several years of apprenticeship to acquire the skills they need. Mass production and computer-controlled manufacturing machines have reduced skill requirements, but traditional manufacturing machines still require skilled professionals for machine adjustments and calibration. 3D printing takes various instructions from a design file and requires less operating skills than an injection molding machine to make the same complex object. Unskilled manufacturing opens up new business models and provides new ways for people to produce in remote environments or extreme situations.

4.No assembly required

3D printing has the characteristic of one-piece molding, which is very helpful in reducing labor and transportation costs. Traditional mass production is based on industrial chains and assembly lines. In modern factories, machines produce the same parts and are then assembled by workers. The more components a product has, the longer the supply chain and product line stretch, and the more time and cost it takes to assemble and ship. 3D printing integrates molding functions and eliminates the need for reassembly, thereby shortening the supply chain and saving labor and transportation costs.

5. Zero-time delivery

3D printing enablesprinting serviceon demand. Just-in-time production reduces a company’s physical inventory, and companies can use3D printingto manufacture customized parts based on customer orders to meet customer needs, so new business models will be possible. Zero-hour production can minimize the cost of long-distance shipping if the goods people need are produced nearby on demand.

6.Unlimited design space

Traditional manufacturing techniques and craftsmen create products into limited shapes, and the ability to create shapes is limited by the tools used. For example, a traditional wooden lathe can only make round items, a rolling mill can only process parts assembled with a milling cutter, and a forming machine can only make formed shapes. 3D printing can break through these limitations, opening up vast design spaces and even creating shapes that may currently only exist in nature.

7. Unlimited material combinations

Today's manufacturing machines have difficulty combining different raw materials into one product because traditional manufacturing machines cannot easily combine multiple raw materials during the cutting or molding process. With the development of multi-material3D printing technology, we have the ability to fuse different raw materials together. Previously unmixable raw materials will be blended to form new materials that come in a variety of shades and offer unique properties or functions.

8.No space, portable manufacturing

In terms of unit production space, the manufacturing capacity of 3D printing is stronger than that of traditional manufacturing machines. For example, an injection molding machine can only make items much smaller than itself, in contrast to a3D printerthat can make items as large as its printing table. After the 3D printer is adjusted, the printing equipment can move freely, and the printer can make items larger than itself. The high production capacity per unit of space makes 3D printers suitable for home or office use because of the small physical space they require.

9.Accurate physical replication

Digital music files can be copied endlessly without any degradation in audio quality. In the future, 3D printing will extend digital precision to the physical world. Scanning technology and 3D printing technology will work together to increase the resolution of morphological transformations between the physical and digital worlds, allowing us to scan, edit and copy physical objects to create exact copies or optimize originals.

What are the Different Types of 3D Printing Technologies?

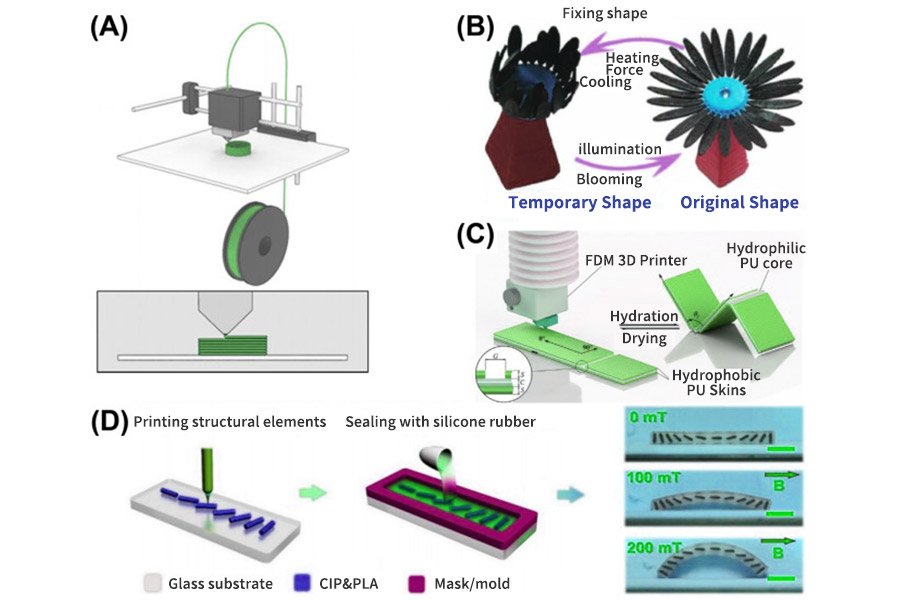

1.FDM

1.1Overview of the technology

FDM(Fused Deposition Modeling), also known as FFF (Fused Filament Fabrication), is the best-known technology, and a part of the Material Extrusion process. It uses thermoplastic materials, typically in the form of spools of filaments. The heated nozzle of the extruder melts the material which is then deposited onto a substrate. There are several advantages of FDM. The printing process is easy to learn, medium-fast and usually doesn’t require a lot of space. The majority of printers are desktop-sized which makes them ideal for the office. But on the other hand, FDMs are also used as big industrial machines, to support manufacturing processes. In such cases, pellet form of the build material can be used rather than a filament.

1.2Materials

FDM allows the use of a wide variety of thermoplastic materials, such as ABS, PLA, PETG, and TPU as the most common, and more complex materials like composites with carbon fiber, glass fiber, or even graphene for conductivity. These materials offer various mechanical, thermal, and chemical properties, allowing you to choose the most suitable material according to the specific needs of the project.

1.3Advantages of FDM

- Non-toxic, but some filaments like ABS produce toxic fumes. Usually it is environmentally safe process.

- Wide range of colorful printing materials, not so expensive, and with high utilisation.

- Low or moderate costs of equipment.

- Low or moderate post-processing costs (support removal and surface finishing).

- Best for medium-sized elements.

- The porosity of the components is virtually zero.

- High structural stability, chemical, water and temperature resistance properties of materials.

- Rather big build volume comparing to other desktop technologies: 600 x 600 x 500 mm.

1.4 Disadvantages of FDM

- Limited design options. Can’t produce thin walls, acute angles, sharp edges in vertical plane.

- Printed models are the weakest in vertical build direction because of the anisotropy in material properties due to additive layer method.

- Supports are needed.

- Not very accurate, with the tolerance between 0.10 to 0.25 mm.

- Tensile strength is approximately two-thirds of the same material that has been injection-moulded.

- Difficult to control build chamber temperature, which is crucial for best results.

- Problem of “stair-stepping” in vertical build plane.

1.5 Applications

- Functional prototyping

- Short-run, bridge, or custom manufacturing

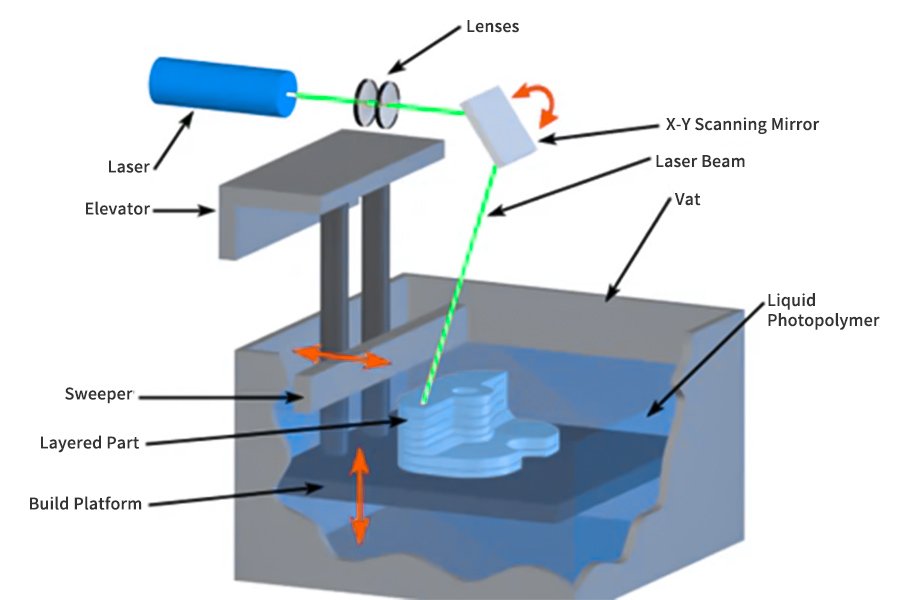

2.SLA

2.1 Overview of the technology

A technique known as photopolymerization is used by stereolithography (SLA), a3D printing method, to produce three-dimensional objects. It was among the earliest methods for additive manufacturing to be created, and it’s still in use today. SLA is commonly used in applications that require high-resolution prototypes, detailed models, jewelry, dental applications, and other industries where accuracy and fine details are crucial.

2.2 Materials

SLA uses photosensitive liquid resins as printing material. These resins are available in a variety of properties, such as stiffness, flexibility, heat resistance, and chemical resistance. Some resins are also designed to mimic specific materials, like ABS, polypropylene (PP), and rubber.

2.3 Advantages of SLA

- Excellent surface finish with layer thickness between 0.05 – 0.15 mm.

- Finished parts can be painted.

- Moderately fast.

- Economical for low production (1-20) parts.

2.4 Disadvantages of SLA

- Expensive materials.

- Post-processing is not only required but also multithreaded, messy process. After the print is done, the resin needs to be washed in an ultrasonic bath or by dunking a part in IPA (isopropyl alcohol), then the supports must be removed and after that, the printouts needed to be cured with UV light.

- The resin alone is toxic, but mixed with IPA is even more dangerous. The liquid should be secured and sent for disposal to a specialized company.

- Waste material is not recyclable and is hard to manage

- Supports are needed

- Printouts are the weakest in vertical build direction due to anisotropy in material properties because of the additive layer method.

- Laser needs to be calibrated periodically

- The layer-thickness may vary in different resins

- Photopolymers are toxic, as well as the fumes that are escaping during the process.

2.5 Applications

- Functional prototyping

- Patterns, molds, and tooling

- Dental applications

- Jewelry prototyping and casting

- Modelmaking

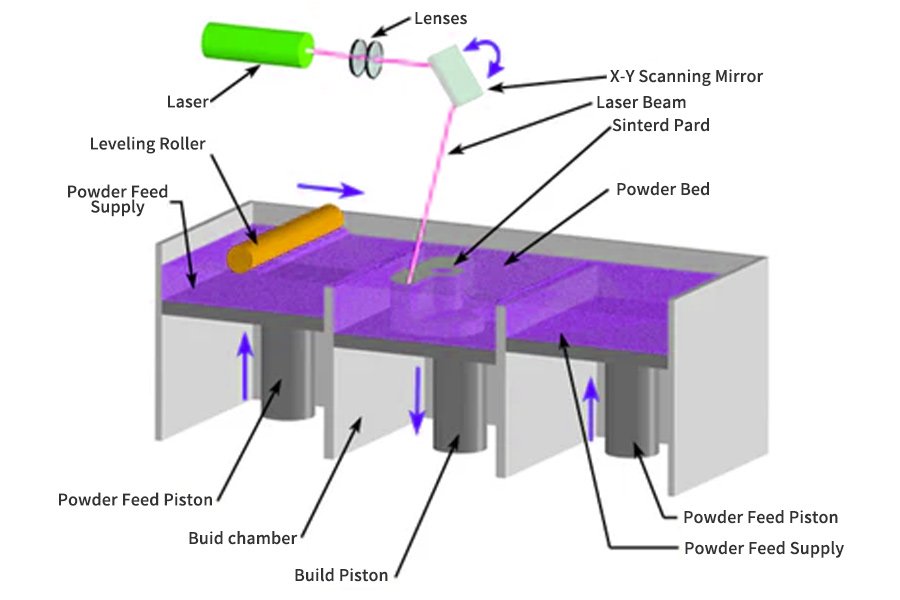

3.SLS

3.1 Overview of the technology

SLS is a 3D printing technology based on the selective fusion of thermoplastic powders using a high-power laser. The machine spreads a thin layer of powder on the build platform, and the laser traces the layer pattern on the powder surface. As the powder fuses, the build platform descends, and the process is repeated for the next layer. SLS is particularly suitable for the production of functional parts and durable prototypes.

3.2Materials

SLS uses thermoplastic powders, such as nylon (PA), polyamide (PA), polystyrene (PS), and thermoplastic polyurethane (TPU). These materials offer strong mechanical and thermal properties, making them ideal for functional and high-performance applications.

3.3Advantages of SLS

- No support structures needed.

- Movable parts with complicated inner geometry.

- Smooth surfaces – it is hard to notice the layer.

- Sustainable printouts.

- Powder is reusable after printing.

- Low to moderate material costs, while using the full working area.

- Desktop SLS 3D printers are inexpensive compared to industrial machines.

- Skilled labour is not required (only desktop SLS 3D printers).

3.4 Disadvantages of SLS

- Industrial machines are expensive.

- Long lead time.

- Cleaning of the machine must be done precisely when changing material to avoid contamination.

- Long printing time (for larger objects).

- For a powder management during post-processing a vacuum cleaner and compressed air is recommended as it can get dusty.

3.5 Applications

- Functional prototyping

- Short-run, bridge, or custom manufacturing

Comparison of the advantages and disadvantages of 3D printing technology

| Parameter | FDM | SLA | SLS |

| Advantages | Low-cost consumer machines and materials Fast and easy for simple, small parts | Great value High accuracy Smooth surface finish Fast printing speeds Range of functional applications |

Strong functional parts Design freedom No need for support structures |

| Disadvantages | Low accuracy Low details Limited design compatibility |

Sensitive to long exposure to UV light | Rough surface finish Limited material options |

What are the applications of 3D printing?

Manufacturing:Used for prototyping, product design and direct manufacturing, and can quickly produce parts with complex structures.

Medical field:In dentistry, orthopedics and other fields, 3D printing technology can produce personalized medical devices and implants, such as dental braces, joint replacements, etc.

Aerospace:used to manufacture complex and precise parts, reduce weight and improve performance.

Construction field:Building materials and even entire building components can be printed through 3D printing technology to achieve innovation in the construction industry.

Educational field:3D printing technology can be used in the educational field to help students understand the structure and shape of objects more intuitively and improve teaching effects.

Food processing:3D printing technology can produce personalized food, such as chocolates, candies, etc., to meet the diverse needs of consumers. In addition, 3D printing technology can also be used to manufacture food packaging and tableware.

What is the History of 3D Printing?

Synonymous with innovation and creativity, 3D printing is not a recent phenomenon. Its origins are much older than you might think.

1940s to 1970s: Imaginative Beginnings

In the 1940s, 3D printing technology was not born in a laboratory but appeared in science fiction novels. Murray Leinster's 1945 short story "Things Pass By" envisions a device that closely resembles a modern 3D printer. Leinster writes that one maker used "magnetoelectronic plastic" to create objects from scanned drawings, a process that mirrors modern computer-automated manufacturing processes.

Likewise, in 1950, Raymond F. Jones introduced the idea of using a "molecular spray" to create objects in his short story "Tools of the Trade," published in Astonishing Science Fiction magazine.

In the 1970s, Johannes F Gottwald patented a liquid metal recorder, an important step towards 3D printing. U.S. Patent 3,596,285A, granted in 1971, describes a continuous inkjet technology using metal powder that enables the shaping and remelting of metal products. This innovation was a forerunner of today's additive technology, which creates three-dimensional objects by depositing layers of material.

The 1980s: A decade of innovation in 3D printing

The 1980s were a dynamic period in the history of 3D printing, as the technology moved from theoretical concepts to tangible breakthrough developments. Significant advances in additive manufacturing technology have led to the filing of key patents, laying the foundation for the 3D printing revolution.

1990s to 2010s:Mature technology and widely used

The 2010s: 3D printing technology has been more widely used and developed. It not only plays an important role in manufacturing, but also shows great potential in many fields such as medical care, architecture, and art.

recent developments

In recent years, with the continuous progress in fields such as materials science, computer science and precision machinery, 3D printing technology has also continued to innovate and develop. New printing materials, printing processes and printing equipment are constantly emerging, making 3D printing technology more widely used, and printing accuracy and efficiency have also been significantly improved. The development of 3D printing technology is a long-term and complex process. It has gone through many stages from early concept exploration to technology germination, preliminary development, key technology and commercialization, technology maturity and widespread application. Today, 3D printing technology has become an important manufacturing technology and plays an important role in various fields.

What is 3D Printing Software?

3D printing software refers to computer programs that can process 3D model files, convert them into instructions that the 3D printer can recognize, and control the printer to complete the printing task.

1.3D printing software features

| Features | Elaboration |

| Modeling and editing | Some 3D printing software provides modeling tools, allowing users to create 3D models from scratch, or edit and modify existing models. |

| Model repair | Before printing, the software can automatically detect and repair errors and defects in the model to ensure smooth printing. |

| Slicing processing | cutting a 3D model into a series of thin slices (slices) for printing layer by layer by a 3D printer. During the slicing process, the software will optimize the printing path and speed based on the shape of the model and the performance of the printer, reducing printing time and material waste. |

| Printing control | Send the sliced data to the 3D printer and control the printer’s printing process, including the adjustment of parameters such as temperature, speed, and extrusion volume. |

2.Common types of 3D printing software

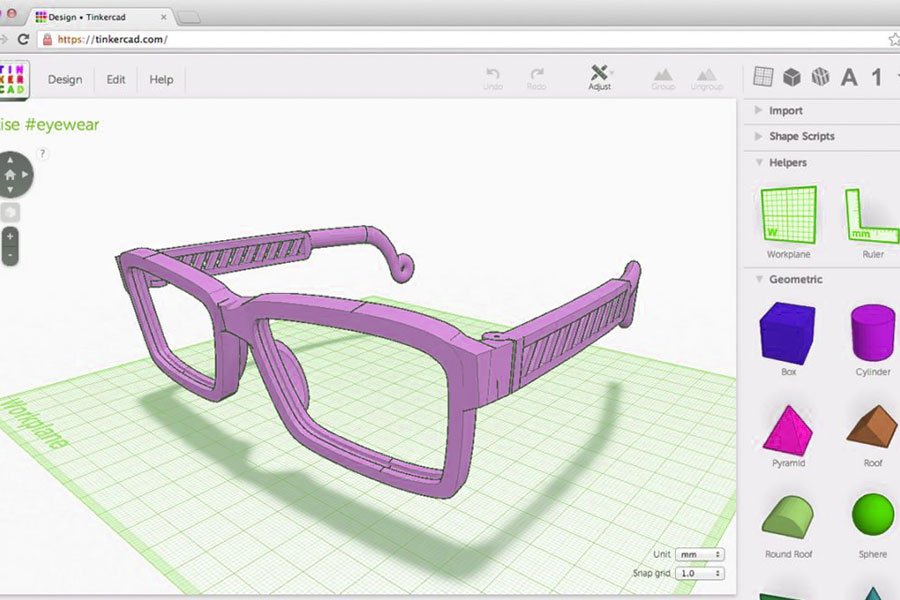

Modeling software: such as Blender, SketchUp, Tinkercad, etc., mainly used to create and edit 3D models. These software usually provide rich modeling tools and material libraries, allowing users to customize model shapes and materials.

Slicing software: such as Cura, Simplify3D, Meshmixer, etc., is mainly responsible for slicing 3D models into a format that can be recognized by 3D printers. The slicing software considers factors such as printer performance, material type, and model complexity to optimize the print path and speed.

Print management software: such as OctoPrint, etc., used to manage and control the printing tasks of 3D printers. These software usually provide functions such as remote monitoring, file transfer, and print queue management, allowing users to keep track of printing progress and status at any time.

How to choose the right 3D printing software?

When choosing 3D printing software, users need to consider it based on their own needs and actual situation. Here are some suggestions:

Functional requirements:Clarify what functions you need, such as modeling, slicing, printing control, etc., so that you can choose software that meets your needs.

Ease of use:For beginners, it is more important to choose software with a friendly interface and easy operation. Some software provides rich tutorials and online support to help users get started quickly.

Compatibility:Make sure the selected software is compatible with your 3D printer and can recognize and control various parameters and functions of the printer.

Cost:Different software has different pricing strategies, including free and paid versions. Users can choose the appropriate software version according to their budget.

In short, 3D printing software is an integral part of 3D printing technology. They provide users with a one-stop solution from design to printing. By choosing the right software, users can complete 3D printing tasks more efficiently and conveniently.

LS: Your partner in 3D printing services

- Multi Material Machining:We have the ability to handle multiple materials, and we can provide professional solutions no matter what material of parts you need to process.

- Competitive Pricing:We provide competitive prices and cost-effective solutions to ensure that customers gain the greatest advantage in cost control.

- Customized Services:Provide customized solutions based on customer design requirements and specifications to ensure that parts meet their unique needs.

- Rapid Delivery:We have efficient production processes and flexible production plans, which enable us to timely deliver customer orders and meet urgent project needs.

FAQs

1.What is 3D technology?

3D technology is the abbreviation of three-dimensional digital technology. 3D means three-dimensional. It refers to a space system composed of a direction vector added to the plane two-dimensional system. This space system consists of three axes: X, Y, and Z. It has long, It has three dimensions: width and height, so it is three-dimensional. 3D technology is a technology system based on the interdisciplinary integration of modern computer graphics, computer vision, sensor technology, human-computer interaction technology and other disciplines.

2.What is the use of 3D printing?

The application fields of 3D printing technology are very wide, covering many aspects such as manufacturing, aerospace, healthcare, architectural design, food processing, education,printing shopengaged in the art and creative industries. With the continuous advancement of technology and the continuous expansion of application fields, I believe that 3D printing technology will bring more surprises and conveniences to mankind in the future.

3.How does 3D printing work?

3D printing is a production technology that converts digital models into physical objects. Its working principle is relatively intuitive and complex.

First, a digital 3D model needs to be created using computer-aided design (CAD) software or other3D modeling software. After creation, users can export the3D modelto 3D file formats such as STL and OBJ. Then, import the 3D model file into the 3D printing software, and the software will generate a series of thin slice information based on the model data. Place the selected printing material into the 3D printer. Finally, the printed model is post-processed.

4.What is 3D printing in simple words?

3D printing is a technology that uses adhesive materials such as powdered metal or plastic to construct objects by printing layer by layer based on digital model files. It is implemented using a digital technology material printer, which is similar to a traditional printer, but the printing object changes from paper to various physical materials.

Summary

With the continuous advancement of technology and the continuous innovation of materials, the future development prospects of 3D printing are infinitely broad. We can foresee that in the near future, 3D printing will become more popular and convenient, costs will be further reduced, and accuracy and speed will continue to improve. At the same time, with the integration and application of artificial intelligence, Internet of Things and other technologies, 3D printing is expected to achieve more intelligent and personalized production and service models, bringing more surprises and changes to human society.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

This article was written by multiple LS contributors. LS is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.