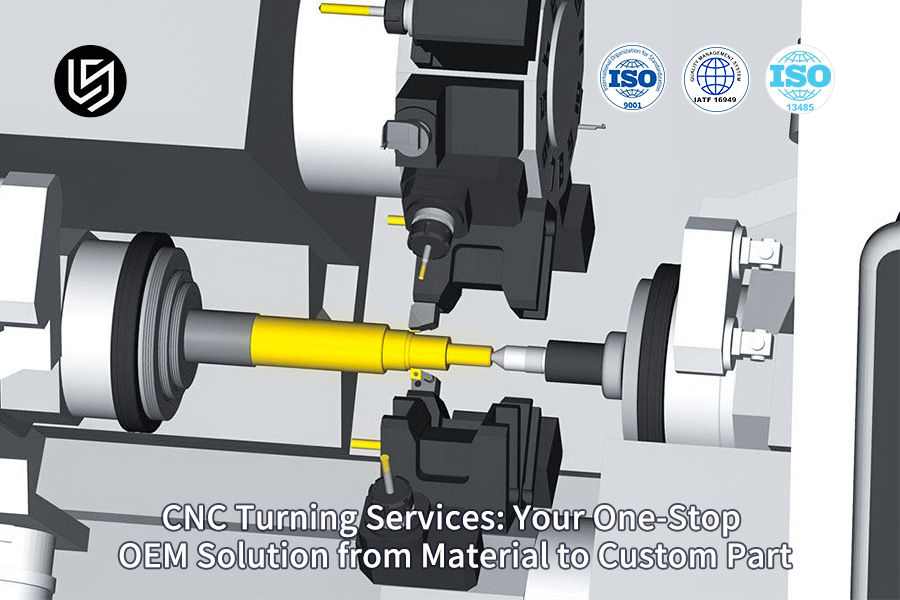

CNC turning services are an essential requirement in the manufacturing industry, but, as has been witnessed, it has been difficult to find a trustworthy supplier for the same at times. The engineers of OEMs, or the purchasing manager, as the case may be, have at times found themselves in a situation where they are confronted with challenges as regards flexibility, delivery, and cost of such services. At times, the situation even becomes tougher, particularly in low volume production, as flexibility is required, which at times is not possible.

In general, problems such as informed above, which also get generated in CNC turning service, would prove to have their roots in some points such as the unavailability of suppliers in offering required knowledge in terms of technology, quality, and flexibility in supply chain terms. There seems to be some sort of communication mismatch in this regard, which, at times, forms some sort of misinterpretation aspect, which seems to crop up at times in terms of specifications. quality, and be customer-centric in having a streamlined process right from design to manufacturing.

CNC Turning Services: Quick Reference Guide

| Section | Key Points | What It Means for You |

| Pain Points | Quality is not stable. There is a delivery delay. The item being quoted is not clear. There is a challenge in accepting small order tasks. | These are all indirect effects on time, cost, and productivity. |

| Root Causes | Limited technology capabilities, lack of effective systems, inflexible supply chain management, communications problems. | It enables poor communication, rework, and hidden costs. |

| Solution Framework | The use of advanced technology and quality control procedures in combination with the provision of a service-oriented and fully integrated managerial concept. | The hardist ensures a reliable and safe. |

| Tech & Capabilities | Multi-axis CNC lathes equipped with live tooling, automation, and experienced programmers/operators. | Capable of producing complex, accurate parts. |

| Quality Assurance | Certification, process inspection, SPC process, quality report. | It has to be ensured that the quality of all parts has met exact specifications. |

| Service & Support | Feedback for DFM, response to quote is quick, communication skills are good. | It brings the supplier into the project as a participant or a partner. |

The presence of a turning partner would also be a major consideration in this regard. The CNC turning partner would mean a partner that has very high technical capabilities, along with a very high-quality system, in addition to their approach in partnering with their services. The presence of this partner would eliminate many pain points in this sector, not only in aspect of part fulfillment but also success in your projects.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

CNC turning services allows the expertise, which can only be had in the factory, and not based on theoretical understanding. It is the entire staff of LS Manufacturing that has the understanding of what the situation is in the factory regarding machining of the high strength alloys for the past 15+ years. This is what we are doing. This knowledge allows our success.

Our methodology comprises a rigorous standards-based methodology. Our methodology includes the following standards on Additive Manufacturing (AM) of hybrid parts as per the following guidelines provided by prominent organizations such as the Metal Powder Industry Federation (MPIF) guidelines. This is the cumulative effect of the experience that we have acquired from the supply of more than 20,000 parts based on our experience in related fields such as the tool paths of hard materials to the standards of flawless threaded parts in the critical sectors of erospace and medical applications.

All of the recommendations contained in this manual have come from this successful experience. The knowledge in this book is not the kind of knowledge you would read in an academic text, but the teachings of experience tempered by the fire of gain and the never-ending pursuit of excellence. This, in my opinion, can only be accredited to our success in condensing a better point out of the confusion in order to achieve full success in CNC turning, with a partner who has been instrumental in transforming innumerable turning points into high performance works, as CNC machinists.

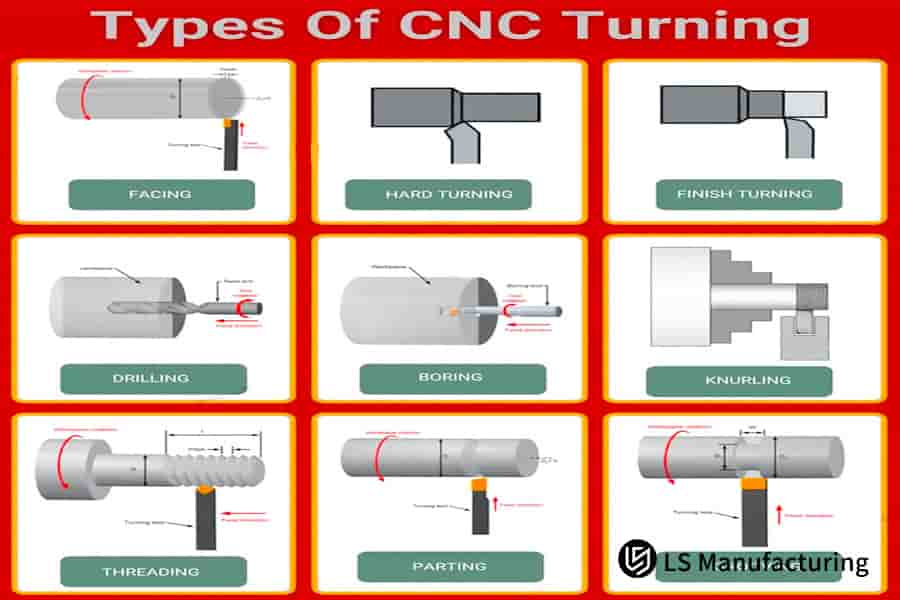

Figure 1: CNC turning reference chart: Operations and material compatibility by LS Manufacturing

How To Choose A Reliable Precision CNC Turning Service Provider?

Selecting a contract manufacturer is one of the more serious business commitments. In this article, we provide you with a quick checklist of some easy-to-follow tips to help you make the right decision. It is important to note that in order to have a good contract manufacturer, you should not look at their cost, rather their total skill set for success. Here follow the right considerations:

Technical and Processing Scope

The foundation lies in verified capabilities. Scrutinize the supplier's equipment portfolio, including the number of axes, machine brands, and condition. A true partner should offer a range of services, demonstrating they are capable CNC turning service providers for both simple and complex parts, with transparently stated standard and achievable tolerances.

Quality Management Systems

Quality uniformity is highly necessary. You have to ask for their presence in their certifications like ISO 9001. These indicate process approaches. More important, though, would be to investigate what happens in their floors. If they have First Article Inspections (FAI) and/or In-Process Inspections? A reliable CNC turning manufacturer would be equipped to have procedures in place to do both and have equipment to support your claim they provide extremely good quality work.

Expertise and Proven Track Record

You have to identify how many years they have actually worked in their businesses. In order to find information regarding what skills capabilities they have in their services, you have to take information regarding their experiences in their previous projects done. These would help to determine their problem-solving capabilities and ensure they can claim themselves to be specialists in their area-of-choice expertise rather than being mere average machine shops.

Communication and Service Responsiveness

Service responsiveness communication would be the root foundations for ultimate effectiveness in potential partnerships. Their responsiveness to their services would be tested within their quotation procedures. Their responsiveness to their services and assistance within their analyzes in their Design for Manufacturerability would have to be tested too. Those in partnerships for suppliers would be none other than those proactive ones in their needs and have good knowledge and comprehension in their requirements.

In summary, how to choose a CNC turning manufacturer involves a holistic assessment. The ideal provider excels not just in machine capabilities but integrates them with robust quality control, proven expertise, and responsive communication. By meticulously evaluating these areas, you can select a partner who ensures project success from the first prototype through to full production, turning potential risks into reliable results.

What Key Materials Can CNC Turning Services Handle?

The performance of a machined component will inevitably be inextricably tied to the material from which it has been machined. Although the importance of CNC turning materials has never been diminished, it is how a given service machines those materials that distinguishes a superior service. The forthcoming section will focus on the nature of the materials, the difficulties in machining them, as well as the distinct processes in both cases to achieve optimal performance in industrial applications.

| Material Category | Key Materials | Common Applications | Processing Considerations / Expertise |

| Common Metals | Aluminum Alloys, Mild Steel | Automotive, Consumer Electronics, General Fabrication | High-Speed Machining, Fine Finishes, Anti-galling. While aluminum alloy turning, it is required that the cutting tool be sharp and also facilitate effective chip removal. |

| Engineering Metals | Stainless Steels (e.g., 303, 304, 316), Alloy Steels | Medical Devices, Food & Beverage, Marine Hardware | Managing work hardening and heat. Stainless steel precision turning demands rigid setups, stable parameters, and sharp cutting edges. |

| High-Performance Metals | Titanium Alloys, Inconel, Tool Steels | Aerospace, Defense, High-Performance Automotive | Extensive tool wear, cooling issues, and stress. Turning services for difficult-to-machine materials require specialty tools with high pressure coolant and custom speed/feed. |

| Engineering Plastics | PEEK, Ultem, Delrin, Nylon | Medical Implants, Semiconductor, Electrical Insulators | Control heating without melting the object and firm tolerance and finished on identified one. |

In summary, a top partner for CNC turning has a diversified material skill set. It’s not about the ability to process a material but rather about process knowhow to tackle the challenges of each material, no matter what they are - heat management in titanium or delivering a sublime finish to a medical plastic.

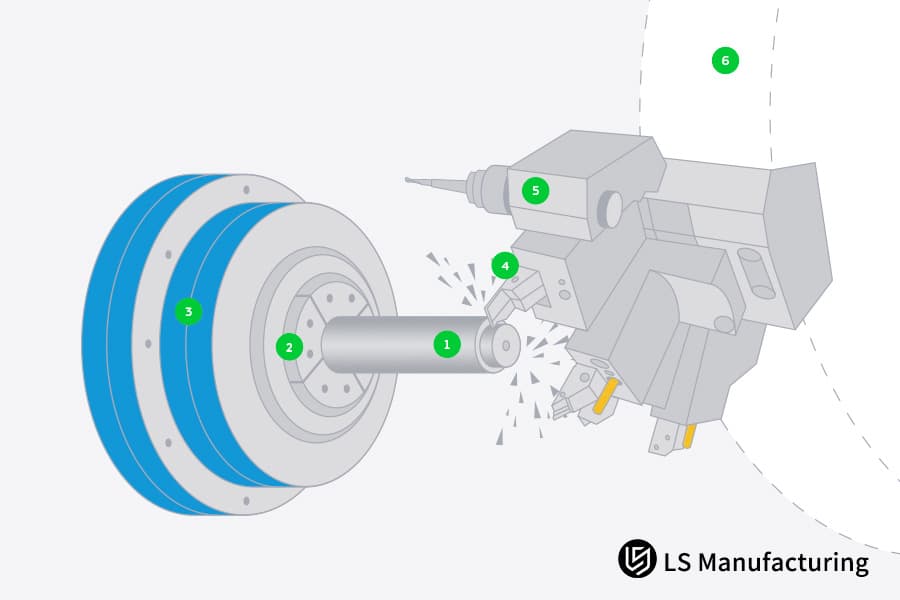

Figure 2: Precision CNC turning for high-volume metal production by LS Manufacturing

How Do You Achieve High Precision And Tight Tolerances For Your Custom Parts Through CNC Turning?

For precision CNC turning processes to attain high precision, it requires the perfect combination that comes with technology, precision, and knowledge. This process is a complete one where all sorts of components, from the stability of the machine right up to the feedback process in the machine, ought to be combined for the perfect result.

| Factor | Role in Precision | Implementation/Capability |

| Machine Tool & Rigidity | Foundation of stability & accuracy. | Highly accurate multi-axis turning machines and mill-turn machines without vibration or thermal distortions. |

| Tooling & Compensation | Exclusive for direct definition of cutting geometry and wear compensation. | Use of quality coated tools, with compensation for the wear of the edges during the cuts. |

| Process & Parameter Optimization | Optimization of cutting force, temperature, and generation of chips. | The development of scientifically optimal cutting speed, feed, and depth of cut for various materials through experimentation and improvement in CNC turning technology. |

| Measurement & Metrology | Enables closed loop control and verification. | In-process probing and dimensional verification on CMMs and optical comparators. SPC process information and CpK values. |

In concluding, tight tolerance turning is not a process; it is an environment. The integrated process that follows logically attests to custom parts machining accuracy when the world CNC turning technology is applied diligently to your tolerances that are not only focused upon, but also meet for each part

How Is The Price Of CNC Turning Calculated For Mass OEM Production And Small-Batch Customization?

To effectively budget, it’s imperative to understand what gives value to the price quote. CNC turning service quotes is not an arbitrary number. It’s the other way around. It’s the total cost of the concrete elements. For production and prototyping purposes in general, the actual cost is the visible application of knowledge for your project. The recipe for success consists of the following main ingredients:

Material and Programming Costs

Every process involves material and programming. A cost basis of cost of qualified metal or plastics stock material is available. Furthermore, engineering manpower effort would be involved in CAM programming & designs related to fixtures, which would provide optimum result. This initial, fixed cost is amortized over the total production volume, significantly impacting the unit price for small batch customization costs versus large runs.

Machine Setup and Cycle Time:

The machine's operational time is a key cost driver. This includes the fixed setup time for calibrating tools and workholding, and the variable cycle time per part. While setup is a one-time charge, OEM bulk processing quotes benefit immensely from spreading this fixed cost over thousands of parts, dramatically reducing the per-unit expense.

Secondary Operations and Quality Assurance

Now, most of the components undergo secondary operations to complete the value chain after the raw machining process has been completed and finished. Activities connected to deburring, surface finishing, anodizing & plating in CNC machining facilities, as well as activities connected to heat treatment, have very costly natures. More specifically, activities connected to quality assurance, beginning with an analysis on the first production part to SPC activities, are included in the overall cost structure provided in an extensive CNC turning service quotes.

In summary, evaluating CNC turning prices requires a holistic view. While bulk orders achieve economy of scale, a proficient partner like LS Manufacturing also optimizes small batch customization costs through efficient workflows and expert process planning. The goal is a fair CNC turning OEM price that accurately reflects the quality, precision, and reliability engineered into every part, regardless of order size.

Figure 3: Precision custom CNC parts with rapid delivery by LS Manufacturing

Aerospace Field: Precision Turning Of High-Temperature Alloy Turbine Housings

In a real-world situation, in the LS Manufacturing case, the ability of our company to provide substantial value in challenging circumstances can be proven. Taking into consideration the challenging demands in aerospace parts machining, the members of our company have demonstrated the application of our knowledge to provide exceptional performance in the part.

Client Challenge

An aerospace manufacturer encountered a critical bottleneck in a new engine program. The challenge was the custom CNC turning of Inconel 718 turbine housings, where the previous supplier's processes led to a 70% yield due to uncontrolled distortion and micro-cracks. This high failure rate critically endangered project timelines, highlighting the extreme difficulty of achieving reliable high temperature alloy turning solutions.

LS Manufacturing Solution

Our system-level solution was developed by the team of engineers at LS Manufacturing solution. We implemented a patented approach wherein the machining path was integrated with a special high pressurized coolant for handling thermal stress. A special fixture was incorporated for increased rigidity, along with in-process probing for adjusting the tool in real time for achieving accuracy for the entire machining process.

Results and Value

The rate at which the final part was being developed saw an improvement at an incredible rate of 98.5 percent, and the percentage increase in the reduction in the time for delivery shot up by an incredible 30% to totally nullify the time for delivery. Add to that the savings on costs on account of this solution, which was in excess of 15% in itself, to totally affirm their confidence in LS Manufacturing being their technical partner in enabling them to solve an “unsolvable” problem in the form of providing them with an improved part.

This particular LS Manufacturing case illustrates the point we are making about our leadership position in the industry related to aerospace parts machining. Our goal of utilizing our special knowledge and process controls in a specific way is made possible by the success we have in high temperature alloy turning solutions. This particular case study illustrates the point we are making about our continued search for excellence in custom CNC turning.

Are you ready to achieve your exact part designs? By clicking on this link, you will get your own turning solution.

In Addition To Turning, Do Your Parts Require Other Machining Services?

In most of the complex areas, many key features cannot be produced by the fabrication of a turning process. Several processes, for exemplifying benefits, can be carried out. These are the situations where milling and turning machining services matter.

- Enhanced Precision and Efficiency: Combining operations on a single platform, such as a multi-axis mill-turn center, significantly boosts precision. It eliminates the cumulative errors from multiple setups and handling between different machines. This integrated process is a cornerstone of advanced multi-axis machining solutions, ensuring all features are machined in a single, controlled coordinate system for optimal part integrity.

- Accelerated Lead Times and Simplified Workflow: An integrated approach dramatically compresses the production timeline. By performing turning, milling, drilling, and tapping in one continuous operation, we remove the queue times and logistical delays associated with moving parts between separate workstations. This streamlined workflow is a key benefit offered by a true one-stop CNC machining manufacturer.

- Superior Design Freedom and Part Complexity: There is the opportunity to achieve even complex designs when undergoing the centering process for turning and milling operations. Such designs can take the form of off-center parts, crosses, or even complex designs for turn parts that have always been impossible to achieve in reality.

- Supply Chain Simplification and Cost Control: When you rely on only one supplier for your machining needs, you automatically remove the cost of administering an agreement and the variables associated with quality are reduced to a significantly large extent. When you partner with an expert one-stop CNC machining manufacturer, you automatically derive the advantages of both supply chain simplification and cost management.

In conclusion, the trend in the provision of milling and turning machining services is in relation to a significantly newer concept in the world of manufacturing. The benefit derived in this context consists of the attainment of not only the product but the entire service involved, which communicates better accuracy, faster completion, and enhanced flexibility in terms of designs. Using the services brought by the provision of the newest multi-axis machining solutions discussed above, you would be able to benefit from the advantage in your own context as well.

What Is The CNC Turning Service Process Of LS Manufacturing From Inquiry To Delivery?

A full manufacturing collaboration to create a successful product requires complete transparency and cooperation. With time, LS Manufacturing has developed a proper step-by-step procedure CNC turning service process, which provides accuracy and dependability in effectively communicating with their clients from the concept to completion.

- Requirement Analysis & DFM Feedback: It all begins with the detailed study of your designs or 3D files. Our engineers discuss openly to understand your intended use, material selection, and performance requirements. Apart from that, we would like to make our Design for Manufacturability comments available to you without cost as part of our strategy to help your part achieve optimal performance, quality, and value.

- Transparent Quoting & Order Confirmation: Clearly present the quote and confirm the order: This is the last step of the technical review, whereby the client is issued with a completed transparent quote. It shall be a clearly broken-down document for the breakdown of costs and timelines. The moment this is realized, then the order is confirmed, and your project goes into our production schedule, thus the commencement of the formal customized machining steps.

- First Article Inspection & Production: The precision process has now begun. In this step, we will be producing a first article sample, which then undergoes a very detailed inspection. The results will be presented to you in a detailed report, just for confirmation, before going to produce a whole batch according to your order, also to be continuously monitored all through with in-process quality checks.

- Final Quality Assurance & On-Time Delivery: Once the products have been produced, they are further tested for quality according to your specifications. When this is done, the products are then carefully packed so that they are not damaged during transit. This ensures the products are delivered on schedule. This marks the end of the professional CNC turning service process.

In other words, LS Manufacturing customized cooperation process involves and benefit from clarity in collaboration with tough quality gates. A process such as this, to customized machining steps, organized, and dynamic, can rule out risks: misinterpretations will not occur, and you will know each step of the way what is happening to ensure everything is just right, from sketch to the final finished part in your possession.

Figure 4: Specializing in custom CNC turning for precision OEM components by LS Manufacturing

How To Get Started On Your Custom Project? Get A Free DFM Analysis And Quote Now!

Getting a project for custom precision parts started should be straightforward and clear. The best possible way this could start would be a professional review of your project. This, in fact, is where the free expert service we provide brings immense value to the table.

- Share Your Design for Expert Review: It is easy to get started. You can upload your 3D model or technical drawing through our secure portal. This starts the dialogue and allows our engineering team to initiate the review. At this point, there is no cost. It is simply the opportunity for an expert review. The easiest way to get a free quote is to share your vision with us.

- Receive Actionable DFM Feedback: We provide a review of your part designs by our engineers for manufacturability, tolerance analysis, and material selection. We will provide you with feedback about how optimization will increase the part's reliability by giving you insight into possible improvements based on reduced production risks. Our free DFM analysis is one of the cornerstones of our entire service, with opportunity optimizations that provide direct savings in improved performance.

- Get a Transparent, Detailed Quotation: Based on the reviewed and optimized design, you will receive a comprehensive and transparent quotation. It will clearly outline costs, lead times, and any recommendations. This document is your roadmap, providing full clarity before you commit. To move forward with confidence, simply inquire now to begin this detailed quoting process.

- Collaborate and Launch Your Order: Once the proposal is accepted, we iron out all the details of the proposal with you. At this stage, your project has now been officially scheduled, and we assign you a team of experts who will be your single point of contact. This is where the process of working with a trusted collaborator start customizing, making the process smooth right from conception to production.

First, making your own project has just been made simple. By booking the decision to inquire now, you have also unlocked a free DFM analysis. This will try and provide you with all the information that you need to make an educated decision and start customizing with a partner that cares about your success from the very beginning.

FAQs

1. What is the minimum tolerance for CNC turning?

Normally, for the standard CNC precision turning process, we can provide the value of the tolerance control as ±0.01mm. In some other products that require an extra need in precision tools, with the optimization of the cutting process, we could provide the ultra-precision machining value as ±0.005mm in order to reach temperature compensation for precision machining tools.

2. Are there any prototyping or small production runs possible? What are the minimums?

We would also like to draw your attention to the fact that R&D services related to innovation are involved in the sense that the services can be availed right from prototyping to small batch manufacturing. Further, technical consulting services are also provided on the 'zero MOQ' process in the sense that the valued clientele can make use of professional levels related to the technical consulting services apart from the production-related services from the 'proof of concept and functional testing' to the 'trial production' phase.

3. What is a quotation? How long will be required for responding to a quotation?

A document for the quote request, together with a file containing either the 3D file STEP/IGES/X_T or the doubly annotated 2D related to the engineering drawing, would be perfect for an exact quote. It may take around 1-2 hours of business time for conducting the said analysis.

4. How can I ensure the security of my design drawings and IP information?

To make certain that we are able to provide an effective mechanism for ensuring that we have a strong IP protection mechanism in place, we developed a full-proof IP protection mechanism wherein we go into a binding NDA agreement as soon as the inception level of our very own project, and our technical info is kept in a different IP-protected server with multi-layered encryption.

5. What about possible surface treatments & post-treatment?

For all these surface finishes, we also have the capability to deliver, according to the process of anodizing, hard anodizing process, and all other surface finish process, whether it is nickel or chrome plating or even electroless nickel plating, sand blasting of varied grit size, passivation, laser engraving, and all other such surface finishing techniques. For each one of these surface finishes, there is a distinct process that is different from one another because of its varied characteristics concerning environment, aesthetics, and many more.

6. Can I have some information on average production cycles?

It will require 7 to 15 working days for completion of a cycle of the production process based on the level of difficulty of the work depending on the product. In respect of the matter in hand, an individual channel of the process will require an earlier turnaround time of 50 percent.

7. Are full inspection reports and certifications of the material available?

Currently, our firm is under a tough traceability process with regard to quality. In this case, all the consignment shipments for the products will carry all the necessary documents for the quality of the products in a package such that the documents would be composed of the FAI, Final Dimensional Inspection, Material Quality Certificate MTC, heat treatment report card, where necessary, and surface treatment inspection, among others.

8. If defective components are discovered within the acceptance process?

Commitment to overall quality assurance. Within the acceptance process, should difficulties arise owing to quality assurance difficulties entailed within our own manufacturing processes, a problem response procedure shall be initiated within 24 hours for providing urgent rework options or complete refunding, as well as technical compensatory alternatives. A specified quality engineer shall be allocated for the complete follow-up procedure for ensuring the complaint is resolved.

Summary

It is important to choose the CNC turning services supplier in order for the project to be successful. It is noteworthy that over these past years, with advanced technological know-how and quality in the sector and even with our experience in aerospace: precision turning of high-temperature alloy turbine housings, we have managed to come out as one of the key partners for the OEMs.

Your project deserves better and more efficient manufacturing-related support. Simply click on the "Get a Free Quote" link to upload your designs, and our application engineers will send you, in 24 hours or less, your personalized report about the results of our DFM analysis, together with your price quote.

Get a personalized quote now and unlock the manufacturing potential of your products. Click to contact us!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.