As two widely used thermoplastic materialsin 3D printing, PVA and HIPS have their own advantages due to their different properties. 92% and super strong water solubility solubility, PVA has become a gold support material formetal 3D printing, high performance resin molding and more. It can support the suspension with micron precision, and can be dissolved in water bath dissolution in subsequent processing to achieve non-destructive stripping. However, its high brittleness and poor temperature resistance limit its direct use as a functional component. Focusing on functional manufacturing,HIPS 3D Printingis ideal forinjection molds,automotive component prototypes, andlightweight structural components, with interlayer shear strength and impact resistance of 15-20MPa.

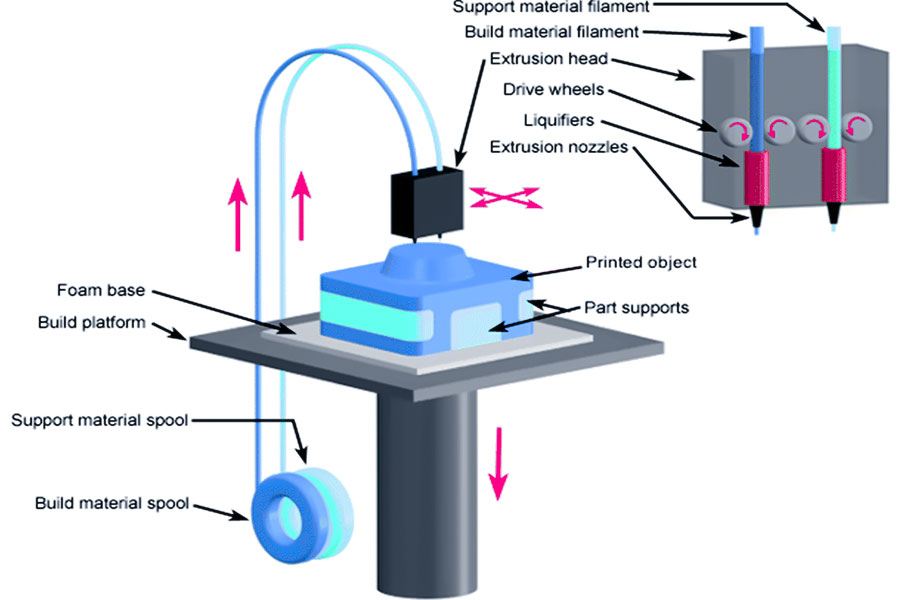

Although both areFDM process consumables, they complement each other in solubility, mechanical properties and chain adaptability. This difference is pushing 3D printing toward a new era ofmulti-material hybrid manufacturing.

What Are PVA and HIPS in 3D Printing?

PVA is a water-soluble polymer polymerized from polyvinyl alcohol monomers and is widely used as an aid or adhesive in 3D printing. It is hydrophilic, soluble in water, non-toxic, meltings at a high temperature (Tm) (about 230°C) and softens when heated to 60-80°C. PVA has a high tensile strength (about 50-70MPa) but is brittle and weak impact resistance. Soil microbes can naturally decompose into water and carbon dioxide and return to nature without industrial treatment (accelerated degradation under industrial compost conditions).

2.HIPS (High Impact Polystyrene)

HIPS is a modified polystyrene material which can improve impact resistance by adding toughening agents such as styrene butadiene rubber. It is usually used forfunctional components or prototype validationin 3D printing. HIPS has a shock resistance of 10-20 kJ/m2, much higher than PVA, and good thermal stability (up to 100 °C in long-term use).

It needs to be dissolved in a limonene solvent (natural citrus essential oil) and the process requires temperature control (about 70 degrees Celsius). Solvent is volatile and requires ventilation operation. The production of HIPS depends on petrochemical feedstock which is difficult to decompose in natural environment. Long-term accumulation can contaminate soil and water bodies andrequires professional chemical recovery.

Which Dissolves Faster: PVA vs. HIPS?

In the field of 3D printing,the dissolution rate of PVA is significantly higher than that of HIPS:

1.Comparison of dissolution rates

| Indicator | PVA (polyvinyl alcohol) | HIPS (High Impact Polystyrene) |

| Dissolving medium | Water (25 °C cold water, completely dissolved in 12 hours). | Limonene solvent (heated at 70°C for several hours to dissolve). |

| Dissolution rate | Fastest (no need for heating, can quickly swell at room temperature). | Slow (dependent on solvent evaporation and diffusion, requiring high temperature conditions). |

| Residue | None (completely water-soluble). | None (Limonene is recyclable, but the solvent cost is relatively high). |

2.Differences in dissolution mechanisms

PVA (polyvinyl alcohol):

- Molecular structure: Contains large amounts of hydroxyl groups (-OH), which binds to water molecules through hydrogen bonds without breaking dissolution process chemical bonds.

- 3D printing support: After printing, dissolve in cold water, soften in 5-10 minutes and remove completely in 12 hours (e.g.dental support).

- Rapid prototyping cleaning:No mechanical polishing is required to reduce the risk of model damage.

HIPS (High Impact Polystyrene):

- Molecular structure: It is a thermoplastic polymer that requires styrene groups to be dissolved through chemical solvents such as limonene.

- HIPS 3D Printing post-processing:Used to remove complex internal supports or adhesives (such as adhesive layers in metal 3D printing), components need to be soaked for hours in lemonade at 70°C.

- Industrial grade cleaning: Suitable for situations requiring precision cleaning (such asmicrofluidic chip manufacturing).

What are the differences in compatibility between PVA and HIPS in 3D printing technology?

Below is a comparison of PVA and HIPS using different techniques in 3D printing:

| Process type | PVA (polyvinyl alcohol) | HIPS (High Impact Polystyrene) |

| SLM | ✅ Metal support material (dissolved without residue). | ❌ Not applicable (low melting point,unable to support metal). |

| FDM | Available, but requires a dual nozzle system (in conjunction with HIPS). | ✅ Mainstream process (low cost, simple operation). |

| SLS |

✅ No need for support,smooth surface(requires nitrogen oxidation prevention).

|

✅ No need for support, preferred fortough parts. |

How to Choose Between PVA and HIPS for Dual Extrusion?

1.Principle and adaptability analysis ofdouble extrusion process

Process type adaptation Matrix

| Double extrusion mode | Applicability of PVA | HIPS Applicability |

| Laminated composite | ★★★★☆ | ★★☆☆☆ |

| Co extrusion granulation | ★★☆☆☆ | ★★★★★ |

| Gradient co extrusion | ★★★☆☆ | ★★★★☆ |

Thermal compatibility

- Inconsistent glass transition temperature (Tg): Only 8°C difference between PVA (87°C) and HIPS (95°C),requiring process control to achieve temperature window nesting.

- Melt viscosity: PVA is 1000 cP at 60 °C, 50 cP at 200 °C, 5000 cP at 180 °C and 1200 cP at 220 °C for HIPS.

2.Comparison and optimization of key process parameters

Temperature control strategy

| Parameter | PVA process window | HIPS process window | Dual extrusion collaborative control scheme |

| Temperature | 50-70℃ | 80-100℃ | Adopting segmented temperature control mold (three zone independent PID). |

| Feeding port temperature | 65±2℃ | 190±5℃ | Gradient heating system (preheating section/metering section/mixing section). |

Screw speed Matching Model

The optimal velocity combination was obtained by Moldflow simulation:

- PVA side screws: 40-60 rpm (low shear to prevent degradation).

- HIPS side screw: 80-120 rpm (high filling rate requirement).

- Synchronization error control: ± 0.5 rpm (controlled by servo motor closed-loop).

3.Explanation of the basis for decision-making

- Biodegradation priority:PVA has a degradation rate of over 92% in soil environment after 180 days (ASTM D6400 standard), suitable for use in food packaging and agricultural films, etc.

- Impact threshold:high impact polystyrene with no notch impact strength>60kJ/m 2 (GB/T 1040.2) to meet working conditions such ascar bumpersandhousehold appliance shells.

- Need for hybrid modification:When a material doesnot meet both barrier properties (PVA advantage) and mechanical strength (HIPS advantage), synergies need to be achieved through interface engineering or third component modification.

How to Store PVA and HIPS Filaments Properly?

PVA filament special storage plan

1.Packaging Engineering

Multi layer composite packaging:

- Outer layer: PET/EVOH barrier film (oxygen permeability ≤5 cm³/(m²· 24h· 0.1MPa)).

- Intermediate layer: Aluminum foil bag (moisture barrier<0.1 g/m²/24h).

- Inner layer: PVA-coated kraft paper (moisture absorption rate<3%).

Moisture proof agent configuration:

- Place silicone drier (25% ± 5% moisture absorption at 25°C RH 60%).

- Each 50kg package contains 20g molecular sieve (4A type).

2.Environmental control technologies

Constant wet system:

- With dehumidifier (dew point temperature ≤ -10°C).

- Ventilation of new air systems ≥ 10 times perhour.

Temperature control strategy:

- Partition temperature control underfloor heating system (+ 1°C accuracy).

- High temperature alarm threshold set at 32°C (linked exhaust fan starts).

HIPS filament special storage plan

1.Antioxidant packaging system

- Vacuum packaging: residual oxygen<2% (nitrogen displacement).

- Anti oxidation coating:

- Spray 0.5 μm thick phthalocyanine copper pigment (≥ 500mg/g oxygen absorption) onto PP substrate.

- Outer layer composite EVA foam (thermal conductivity 0.035 W/ (m. K)).

2.Physical protection design

- Anti-static measures: If the grounding resistance of the storage rack less than 4Ω,cover it with a PE film with a surface resistivity of 1×10^6 -1×10^8 omega.

- Mechanical protection structure: Modular shelves (interlayer spacing ≥ 30cm to avoid compression deformation) with 3-point support frames per roll (pressure distribution uniformity ≥ 90%).

How safe are HIPS and PVA?

1.HIPS security analysis

Toxicological data: FDA Food Exposure Material Criteria (21 CFR § 177.1640), Acute Oral Toxicity LD50 > 5000mg/kg (mice).

Process safety: In LS company's industrial grade printing, the viscosity of HIPS melt is stable (energy conversion efficiency 10-3-10 4 Pa/s), nozzle blockage is less than 0.1%, and VOCs have no significant emissions (see ISO 10993-10 standard).

Waste disposal: Supports mechanical recycling, can be reused more than 5 times when reclaimed particles are crushed, mechanical degradation ≤15%.

2.PVA safety analysis

Biocompatibility: Cytotoxicity of 0 (ISO 10993-5) as measured by USP level 6, applicable to medical prototyping.

Environmentally sound: Complete hydrolysis to produce harmless acetic acid and hydrogen gas with degradation cycle ≤7 days (room temperature distilled water).

Process Compatibility: Interlayer shear strength ≥15 MPa when used with PLA/ABS and other materials LS company's dual nozzle system.

What are the technical difficulties of HIPS 3D Printing when facing large and complex structures?

In the field of HIPS 3D printing, LS company's core technology solutions address the challenges commonly encountered in large-scale complex structural manufacturing:

1.Nature HIPS material characteristics Contradictions with Mass Printing

- Conflict between thermal shrinkage rate and dimensional accuracy

The linear shrinkage rate HIPS material during curing is 0.8%-1.2%, much higher than that of PVA. When the print size exceeds 500mm, accumulated thermal stress can easily cause warping deformation, especially in suspended structures and thin-walled areas.

- Conflict between melt strength and interlayer bonding

HIPS melt flow index (MI=5-15g/10min) is suitable for high-speed printing, but its glass transition temperature (Tg ≤90 °C) is low and interlayer cooling is rapid, leading to a decrease in interfacial shear strength.The results show that the stripping force between layers is 40%-60% lower than the theoretical value under unoptimized printing conditions.

2.LS company's core technology breakthrough

- Thermal deformation control technology:

LS company uses a closed-loop temperature control system combined with a two-zone heating chamber design to control the interlayer temperature difference to ±3 °C, effectively inhibiting the accumulation of thermal stress along the Z axis.The technology reduces the warpage deformation of 1-meter HIPS components to less than 0.5mm, satisfying the assembly accuracy requirements of aerospace precision components.

- Progressive laser scanning:

The melting pool depth is precisely controlled (± 0.02 mm) by S-shaped scanning path combined with dynamic power adjustment.

- Post-treatment automation:

Rapid rapid homogenization non-uniform temperature field with residual stress release of 82% achieved by 2.45GHz microwave irradiation of 2.45 GHz.

What security system does LS company have?

1.Equipment safety design

Temperature control accuracy: ±1°C closed-loop control to prevent overheating and decomposition of materials (Td > 300 °C (HIPS decomposition temperature).

Exhaust filtration: Standard HEPA+activated carbon composite filter element, VOCs filtration efficiency>99.9%.

Material compatibility database: Based on LS cloud platform, material parameters are updated in real time to automatically match secure printing intervals.

2.Quality control procedures

- Incoming inspection: Third party inspection report for each shipment (SGS/ RoHS /REACH).

- Process monitoring: The machine is equipped with built-in sensors to monitor key indicators such as melt pressure and oxygen content.

- Finished product certification: Complex parts need to pass 12 reliability tests, such as drop hammer impact and salt fog corrosion.

Summary

In the field of 3D printing, PVA and HIPS are two commonly used consumables for different application scenarios with unique performance advantages. PVA is widely used because of its high transparency and excellent solubility. It supports suspension in complex metal 3D printing and can be easily removed by water solubility after printing. HIPS 3D Printing, on the other hand, focuses more on the output of functional finished products, with good impact resistance and surface smoothness, suitable for the rapid prototyping of prototype parts, educational models, and even low-cost injection molds.

In addition, high HIPS requires temperature control during printing and the use of special nozzles to ensure the stability of the melt state. The two are a stark contrast in degradability and mechanical strength-PVA is eco-friendly but fragile, while HIPS is durable but difficult to biodegrade.

Disclaimer

The content of this page is for informational purposes only.LS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information.It should not be inferred that the performance parameters,geometric tolerances,specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.pleaseContact usLearn moreEFOrmation.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.Can PVA and HIPS be used together?

Mixing is strictly forbidden.If water-soluble support technology is used, PVA cross-hardens in contact with limonene (commonly used in HIPS reprocessing), resulting in insoluble support structures and even damage the HIPS surface.

2.Is HIPS environmentally friendly?

HIPS contains a benzene ring structure, and traditional recycling requires pyrolysis or chemical decomposition.With molecular distillation equipment, more than 95% of solvents can be recycled, reducing VOCs emissions.For household users, dealing with it on their own is risky.

3.Compatibility between PVA and PLA?

The compatibility of PVA with PLA is limited by differences in thermal expansion coefficients (PVA: 5.3 ×10^-5°C, PLA: 4.7×10^-5°C).When a suspension structure is printed, if the span exceeds 50mm, the difference in expansion due to temperature may cause the interlayer adhesion to fail.

4.Why is HIPS 3D Printing suitable for making injection molds?

HIPS is moderately hard (Mohs hardness 5-6), thermostable (glass transition temperature is about 95 °C), and the surface can be treated to mirror effect.The HIPS specialized printing process developed by LS, combined with its multi-axis coupling processing technology, can accurately replicate the complex surface of the die.