Rapid prototyping design requires appropriate planning to avoid cost and time issues. In contrast, designers and suppliers face design issues, confusing supplier prices, and delayed supply delivery, making it harder to proceed with the projects. It is highly essential to mitigate such issues to obtain successful products.

The reason for this can be traced to the absence of a design guide and supplier evaluation process. Experience-based quotations, if they do not incorporate the manufacturability analysis and the optimization of costs, may lead to a sub-optimal solution. In this document, a design guide and scientific approach to quotations will be presented in order to generate improvements.

Rapid Prototyping Design: Complete Cheat Sheet

| Section | Key Focus | Core Principles & Actions |

| Design | Design for Manufacturability | Optimize geometry. Standardize the wall thickness. Design the material. Optimize the tolerance. Add draft angles. |

| Process | Technology selection | DFM for rough function. SLA for fine details. SLS for complex parts. CNC for high precision. |

| Quotation | How to control cost & timeline | Provide complete 3D files specify all requirements. Request itemized quotes. Compare multiple vendors. Explain timeline & revisions. |

| Partner | Factors for partners in Projects | Check technical support. Study quality systems. Check communication. Establish IP terminology. Strategy for post-processing requirements. |

Rapid prototyping must happen through an organized process. If one takes into consideration the principles of design for manufacturability, the prototyping technique to be pursued, and then follows an organized method for quotation acquisition and review, there will be no issue with the cost and time involved in prototyping. Through this, the prototyping stage becomes predictable, and the end product will inevitably progress to the next level of triumph.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

As related to rapid prototyping design, we at the team at LS Manufacturing are definitely at the leading edge and not operating out of a lab. The physical part with such high-strength alloys and geometries has been occurring every day in the real world. Take every single bit of advice contained here—each has directly emerged out of this struggle to ensure that every bit of information here can be applied directly.

Our expertise is gained through delivering over 50,000 precisely CNC machined parts for high-demanding industries. In the prototype development stage, for example, within the aerospace industry, or within the development of an implant, one error could be potentially life-threatening. The knowledge of quality that we have gained, within a strict model such as ISO 13485 for Medical Devices and IATF16949, implies that we are inspired by an unending quest for reliability and exactness when we offer design improvement suggestions.

This trust, therefore, is that the resource is distilling war zone expertise that spans over a decade. This is not textbook learning that would help with the creation of prototypes and any process but one that is developed by machine coolant and metal shavings and whatnot and has to withstand testing. Our aim, therefore, is to make sure that you don’t go down the expensive path but start on the path of prototype success that our most hardened customers have access to.

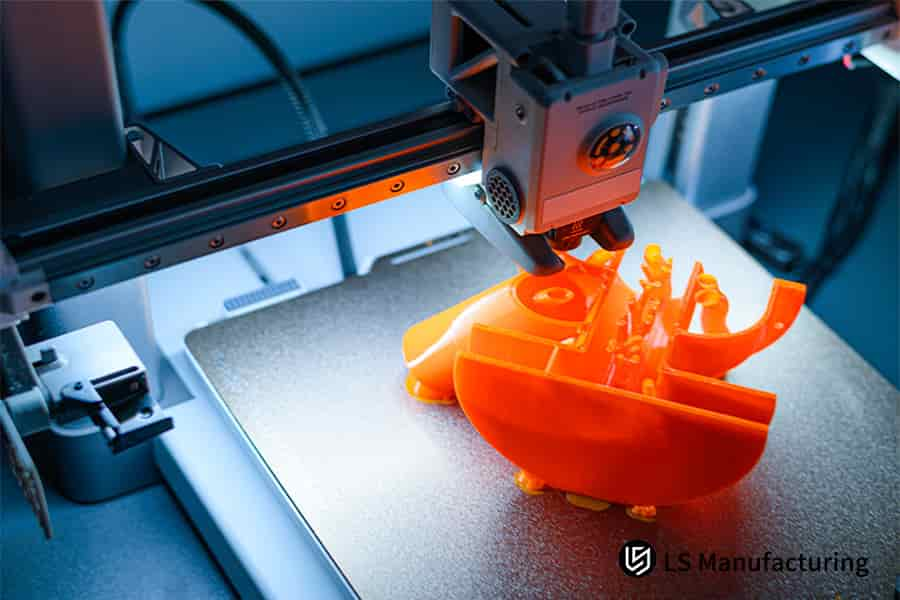

Figure 1: Budget-friendly guide to custom CNC prototyping and production by LS Manufacturing

How To Obtain The Most Accurate Rapid Prototyping Quote Through Design Optimization?

A clear understanding of the cost drivers during the design phase enables the locking-down of a price that is transparent as well as competitive. Indeed, the only accurate pricing is the one offered by the solution resulting from intellectual engineering and efficient production combined.

- Material and Process Selection: The key to an appropriate rapid prototyping quote has something to do with material selection based on functionality for which the part will be used. Each process, whether it be SLA or CNC machining, has a completely different cost factor associated with it. Our team of engineers will be able to guide us on the same.

- Simplifying Geometry to Improve manufacturability: This is because when you have complex geometries like deep cavities, thin walls, and/or tiny inner structures, machining gets processed slowly with more wastage. Therefore, when you simplify your geometry to facilitate easy manufacturing, by definition, you obtain a accurate pricing result.

- Using Smart Tolerances and Finishes: When high tolerance values and high finishes are specified for surfaces that are non-functional, the cost of the production process can rise exponentially. Your design will be checked to make sure that it only specifies precision when precision is required, and your will remain lean and mean.

- Professional DFM Analysis: The most direct path to an accurate pricing estimate is a formal Design for Manufacturability (DFM) check. This is offered for free by LS Manufacturing, where our professionals analyze the three-dimensional files of the product to provide modifications for reduced costs before the products are manufactured.

That is, optimal proactive design will provide you with a rapid prototyping quote for your design optimization. That is, full cost control and visibility can be attained when professionals like ourselves are integrated right from material design refinement, simplifying designs, and setting rational demands to ensure your design is on schedule right from the beginning.

What Are The Core Technical Points That A Complete Rapid Prototyping Guide Should Include?

Effectively, a rapid prototyping design guide is essentially a guideline that acts as a map to develop a concept into a part that can be manufactured. It functions as a connecting medium which bridges the divide from the world of computer-aided design to the physical world through its technical specifications that include notions of best practices for its application.

| Category | Key Considerations |

| Material Selection | Identify material strengths such as strength, heat resistance, and flexibility, and relate them to the purpose of the prototype and the proposed methods of production. |

| Geometric Design | Must comply with requirements on uniform thickness of walls, draft angles, and geometric shapes. |

| Tolerances & Finishes | Use functional tolerances on only essential sizes, and specify necessary surface finishes. |

| File Preparation | 3D files must be clean and closed, as well as oriented and key-sized, for the purpose of quoting. |

Therefore, to conclude, an efficient rapid prototyping design guide must incorporate the preceding highly interconnected technical specifications. If these best practices can be followed, it would facilitate the design team to empower themselves with skills to overcome costly changes, speed up the iterative cycle, and improve the success chances of the first prototype.

How To Optimize The Cost Of Rapid Prototyping While Ensuring Quality?

The rapid prototyping design for cost means reaching the goal through effective engineering and is not at all about compromising or reducing the costs; it's all about cost optimization and aligned quality assurance where every penny spent should make a specific contribution to reach the prototype design and testing goals.

Strategic Material and Process Selection

The first thing that adds to making cost optimization method is the material and processes involved. Our engineers can also tell whether there will be a balance requirement of your cost inputs to determine whether you are using the best suitable material or a cheaper one that could fulfill your requirement of quality assurance through a production process such as urethane casting.

Implementing Design for Manufacturability (DFM)

The most impactful design improvement for cost is simplifying geometry. This involves eliminating redundant complex features, reducing varieties of complex features, and reducing hole varieties. Such kurz changes explained above directly reduce costs and, in many instances, improve the reliability of the components.

Applying Smart Tolerances and Finishes

A description of the rapid prototyping design for cost must be given by the enablement of design, indicating the specification of the definition of the detail tolerances and surface finish in a brilliant way only in those areas of importance, that is, areas of prime function. A targeted approach is a key design improvement for maintaining budget.

Iterative & Modular Design

Use of the design method capable of expressing the design in a modular way for the projects that will implement a few design cycles may be effective for the cost optimization in the context of the research. The concept of design of the family of components on the base component may help to use the similar solution and material that will bring down the costs to a significant extent in the design of the prototype.

Finally, cost optimization in rapid prototyping is about much more than collaboration. Then there is the need to integrate the realities of performance and production through insights from design improvement. Cost optimization for your bottom line is achieved by implementation of key material selections, manufacturability, methodologies, and specification.

Figure 2: Choosing suppliers for rapid CNC machining services by LS Manufacturing

How Can Customized Rapid Prototyping Services Meet Specific Needs?

For instance, it might be specialized when it comes to materials, environment, and geometry. In most cases, when it involves this kind of project, it might not be feasible to rely on a personalized solutions. This service serves as an excellent custom rapid prototyping technique when solutions for such special requirements had already been there.

Handling Properties of Materials

If a custom rapid prototyping service accepting challenging material handling tasks is considered, it will prove to be most effective. These materials may include high temperature alloys, bio-polymers, or maybe some type of composites. The key to success here is profound knowledge of material science, combined with optimized machining settings to address special requirements.

Complex Geometry or Assemblies

In those instances when the work has complex geometry, for example, when passage through an interior region or assembly of multiple parts needs to be performed, then a customized or personalized solution can and must be implemented to ensure the requirements for the final product with respect to form, function, or fit.

It needs to pass on strict certification and testing standards

Those prototype models to be utilised for the final testing purposes in domains such as the airline industry, automotive industry, and medical industry should meet the industry compliance standards. They shall ensure proper personalized solutions in order for the prototype to reach a pass criteria for the compliance purpose of the document.

Integration of secondary operations and finishes

Special requirements are very often accomplished outside the primary fabrication. It should be able to integrate easily with necessary secondary operations, like specialized surface finishes, heat treatment, or bonding, in an overall good custom rapid prototyping solution with the end goal of producing an assembled module that matches the intended environment.

In other words, a valid custom rapid prototyping partnership is much more than just a part-made fabrication service. This is simply because it is a collaborative type of engineering that calls for comprehension of special project objectives coupled with the formulation of personalized solutions that seek to meet unique technical challenges. This ensures the final prototype is more than a model but a solution that has been validated against your most demanding special requirements.

What Key Capabilities Should Be Considered When Selecting A Rapid Prototyping Supplier?

To ensure the right partner insofar as the selection of the rapid prototyping supplier selection process itself could be an important and decisive step, which could involve considerable impacts in several aspects, such as cost alone, success, and time. A full capability assessment, in fact, has to be much more than the price offered by the supplier to his/her capabilities regarding your project.

| Dimension | Key Considerations |

| Technical & Equipment | Check the quality, precision, and material capability, and also DFM. Good for your design demands? |

| Process & Quality | Observe documents on quality systems, processes, or procedures such as the industry quality standard. |

| Expertise & Communication | Analyze the nature of engineering expertise and the nature of communication required in order to work together during the solution of the problem. |

| Reliability & Scalability | Review history for issues of on-time delivery, variability of volumes, or project management/IP processes. |

An efficient supplier selection must blend objective assessment and subjective evaluation. Ultimately, it is those suppliers who are best suited to your needs with regard to project success and an ethic of collaboration that will be the most suitable solution when performing a rapid prototyping supplier selection.

Figure 3: Desktop CNC prototyping with digital design and fabrication by LS Manufacturing

What Are The Key Points Of Quality Control In The Rapid Prototyping Manufacturing Process?

There must be excellence in the rapid prototyping quality control process that is proactive and multi-staged. During this process, the whole production of rapid prototypes manufacturing will be modified to a verified system at the reliability stage to ensure that the rapid prototypes meet the reliability assurance.

- Material Qualification and Traceability: The foundation of reliability assurance begins with verifying the integrity of all incoming raw materials. Rigorous quality control involves material certification checks, lot tracking, and storage condition monitoring to prevent defects from entering the manufacturing process.

- In-Process Monitoring and Verification: The importance of in-process monitoring during the rapid prototyping manufacturing industry can never be emphasized enough. This will include the stages of parameter verification, tool wear measurement verification, as well as dimensional verification. By implementing a system such as SPC (Statistical Process Control) at this point, it will allow for compensations if there is any deviation.

- Comprehensive post-processing and final inspection: Basically, the entire quality control process involves verification even after the part has been manufactured. In general, secondary process validation may include such activities as heat treatment and surface finishing. Advanced CMMs, surface testers, and functional gauges are employed in the final inspection process against each specified criterion to confirm that it meets the requirements.

- Documentation and Feedback for Improvement: A robust manufacturing process includes meticulous record-keeping for every job. This ensures traceability and forms a very critical input or feedback that helps the improvement of the processes of the subsequent jobs. This ensures that reliability assurance is done in a closed loop, converting production history into lasting improvements.

Finally, quality control shall be established in every step of this rapid prototyping manufacturing. This shall cover every step of the manufacturing process, including the receipt of the materials through the dispatch of the same out, within a control and verification program emphasizing the concept of reliability.

How Do Tolerance Design In Rapid Prototyping Affect Manufacturing Costs And Quality?

Tolerance design is one of the key elements in smart precision engineering, whose goal is to address the existing gap between design and reality. A very efficient instrument in rapid prototyping tolerances is related to the application of the type of tolerance, which helps to create balance in the quality and cost control.

- The Direct Link Between Tolerance and Machining Effort: Rapid prototyping tolerances Machines increase the need for lower machining rates, special tools, and layered machining. This takes an exponential turn when your production level increases each digit of accuracy, directly correlating between your cost control.

- Inspection Complexity and Quality Assurance Costs: As tolerances tighten, the precision engineering required for verification intensifies. Meeting a ±0.025mm spec versus a ±0.1mm spec may necessitate advanced CMMs and significantly more inspection time, adding substantial overhead to the quality control portion of your budget.

- Achieving Functional Fit via Tolerance Stack-Up Analysis: The goal of precise design is to focus on what is most important—in contact surfaces, in aligning elements, or in motion. Thus, tight tolerance is only specified in these regions, and the tolerance for the entire system relaxes to achieve functional success. This strategic approach is a hallmark of efficient precision engineering.

- Limitations of Material Processing to Achieve Tolerances: Not all materials and processes will be able to produce the same tolerance. Increasing the level of tolerances beyond the capabilities of your process will result in scrap, rework, and out-of-control expenses. The capability of your precision machining process may be exceeded by the tolerance during an DFM process.

In conclusion, mastering tolerance design is about applying the right level of precision for the right reason. This is because properly considered rapid prototyping tolerances, which stipulates that a level of accuracy should be obtained depending on their function, method, and type, can be highly effective when it comes to costs as well as end quality.

How To Select The Appropriate Rapid Prototyping Material Based On The Application Scenario?

This is one of the effective strategies and may be taken into account while rapid prototyping material selection. The process requires a deep analysis of the application scenarios and a clear understanding of the specific performance requirements the part must fulfill in the real world.

Assessment of Mechanics and Functional Specifications

The initial step in material selection is defining core performance requirements like tensile strength, impact resistance, or flexibility. In a carrying bracket prototype, the requirement could be for high strength in Nylon, and for a flexible gasket, rubber plastics might be required.

The Real-world Implementation Consideration

The real-world application scenarios dictate material behavior. Some materials might degrade in the presence of the UV lights, chemicals, high temperatures, and/or water. Selecting the right materials that will resist the mentioned stresses in the environment will make sure that the prototype will serve its intended functionality for a longer period.

Compatibility of Process vs. Aesthetic Preferences

The chosen process would result in limitations for the material choice. Additionally, the environment under which the material will be used might require a specific surface texture, color, or level of translucency. Since it is a consumer product, the final product prototype must therefore be of a smooth surface. It might therefore rather choose a material suitable for the SLA or PolyJet process rather than the DFM process.

Material Cost Scalability Based on Project Mileage and Budget

Rapid prototyping material selection and decisions have always been the domain where the role of material cost plays an extremely important turning point. One always has the option to select cost-efficient materials to prototype. But when it comes to nearing functionality testing, material cost encompassing the cost that would go to the final material will have a prevailing influence.

Essentially, rapid prototyping material selection process involves a matter of personal judgment, hence not a default procedure. Materials used are a compromise between the mechanical aspect, levels of difficulty, budget, and levels of factors of beauty of a given project. This implies that there will be a judgment of value that will make a well-informed choice based on an aspect that will make a prototype test of design for the value of that design.

Figure 4: Streamlining custom CNC prototyping tolerances, materials, and production flow by LS Manufacturing

LS Manufacturing: Surgical Robot Precision Components Prototyping

This particular instance demonstrates that customized manufacturing solutions actually possess a direct ability to tackle problematic issues. Moreover, establishing a partnership with a developer of a medical device demonstrates that prototyping services with high-tech expertise constitute an imperative component of productive development for an advanced medical solution.

Client Challenge

The customer was asked to design very complex manipulator arms for a new surgical robotic system. This brought about various challenges. The design is highly complex, considering it contains geometries difficult to machine. They had a tolerance of 0.01 mm. Finally, there were very strict biocompatibility stipulations for the contacting components with patients.

LS Manufacturing Solution

A multi-process approach was used. Critical structural features in tight tolerance had been CNC machined. The engineering design had developed supports and paths for the same to meet requirements without compromising the fragile complex shape. Detail housing designs had been produced in high resolution SLA, high-quality surface finish.

Results and Value:

The prototypes developed were of a medical nature. This ensured that functionality testing was undertaken. The strategy adopted the lifecycle stages. It ensured that the time it takes to market decreases by 50%. This ensured that the cost of prototyping a project decreases by 30% for the client. This is what initiated the long-term relationship.

From the project described above, the argument regarding the advantage of personalized prototyping services has been supported. The unique combination of processes and skills enables us to address the challenging requirements concerning high precision and compatibility, as well as efficiently demonstrate the possibility of rapid innovation for the complex medical device.

Want to improve the prototype quality of precision medical components? Click to get a customized solution.

How To Establish An Efficient Collaborative Process For Rapid Prototyping And Manufacturing?

Such integration with design and production functions will lead only to peak efficiency improvement in prototyping. Collaborative process to be more than mere handoffs between functions; this should allow for the creation of an ongoing dialogue space in virtual collaboration.

- Establish milestones and communicate in channels: The most important principle in a successful collaborative process is defined roles, formats of communications, and milestones of communication. Such structuring of the communication system with milestones is allowed to efficiency improvement before they become costly mistakes.

- Implement Centralized Digital Platforms for Real-Time Sharing: A robust digital solution, such as a cloud-based product lifecycle management (PLM) portal, is essential. It provides a single source of truth for 3D models, drawings, and revisions. This ensures all stakeholders access the latest data instantly, eliminating version control errors and accelerating decision-making.

- Incorporate Proactive DFM Feedback Loops: Collaboration as a process involves collaboration as a team, and the need to incorporate the knowledge of the manufacturing team as early as possible is required. The need to incorporate the feedback of the manufacturability of the design is required for the part of the manufacturing engineers. This iterative dialogue, supported by the right digital solution, prevents downstream delays.

- Utilize Digital Tools for Project Tracking and Issue Resolution: An effective collaborative process requires visibility. A shared platform for tracking project status, flagging potential delays, and documenting solutions turns isolated incidents into institutional knowledge. This system provides the clarity needed for continuous efficiency improvement.

Of course, there must exist an optimal rapid prototyping collaborative process that should then be planned for and not happen by default. The optimal collaborative process will utilize effective communication channels, strategic integration of DFM, and an digital solution to the management issue. With the collaborative process available, there will be no friction and optimal iteration cycle speeds will be attained to ensure rapid prototyping.

FAQs

1. How much does the rapid prototyping quote cost?

Price quote is made up of material charges, processing charges, post-processing charges, and charges for tests. It is the most transparent form of price quote because in this nothing is charging in a concealed manner.

2. How is the quote adjusted after design changes?

Next, we assess how changes, if any, that could occur within this 2 hour period will affect us and adjust accordingly our quoting system.

3. How is the cost for rapid prototyping impacted by the type of material used?

The cost of material will work out to be between 30% to 50% of the final price tag. We will supply the form of material that is most optimal for use, as may be desired by you.

4. How do you guarantee the design quality of rapid prototypes?

The level of service we offer includes the analysis of the double factorial matrix, as well as the analysis of the engineering design performed by engineers.

5. What is the minimum order quantity for rapid prototyping?

We support anything from 1 unit to mass production, depending on the needs of product development with the client.

6. Are rapid prototype testing results available?

We provide complete testing reports and material certifications to ensure traceable quality.

7. How do you handle urgent prototype production requests?

We also provide an expedited channel, taking just 3 days, and giving priority access to production capacity.

8. What are the processes you would follow to protect design-related intellectual property rights on behalf of the client?

We do ensure that a continuous stream of leak-proof performance for the past 20 years is recorded due to proper document management practices and the enforcement of good confidentiality terms.

Summary

If the companies follow the guidelines presented in rapid prototyping, it will be possible to get the maximum benefits from the product development process. The experts from LS Manufacturing would be of immense help to the clients right from designing to the manufacturing process.

You can contact the prototyping experts of LS Manufacturing today to arrange for your free design consultation and quote. We will definitely provide you with the best solutions for your project.

Address delivery delay challenges and rapidly achieve high-precision prototyping. Choose a professional rapid prototyping solution to ensure your product development is on full speed ahead.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.