CNC machining is more than just a manufacturing technique, as it is actually a crucial technology for bringing designs into reality. However, many people struggle with designs that keep experiencing changes based on machining variations, with extra costs from prototyping cutting into their bottom line due to lost opportunities resulting from their late designs. Actually, sometimes, the technology might not be the challenge but finding a person with a clear insight into this technology.

These are the typical pains in the industry rooted in the limited understanding of the capabilities available to the industry, and the solution quality to the exact problem, when selecting a technically profound supplier. This handbook is here to turn the paradigm around, to provide more than just the technological understanding, but the whole methodology for partnership by example in the area of the aerospace industry with the 40 percent shorter production time and the 30 percent cost savings.

CNC Machining Full Text Quick Reference Table

| Module | Core Theme | Content |

| Technical Fundamentals-Concepts and Basic | Benefits The method of instructive methodology in a digital way is explained | how the Computer Numerical Control-CNC directly controls the movement of machine tools, and how automation, precision, and reliability go further than conventional ones in machining. |

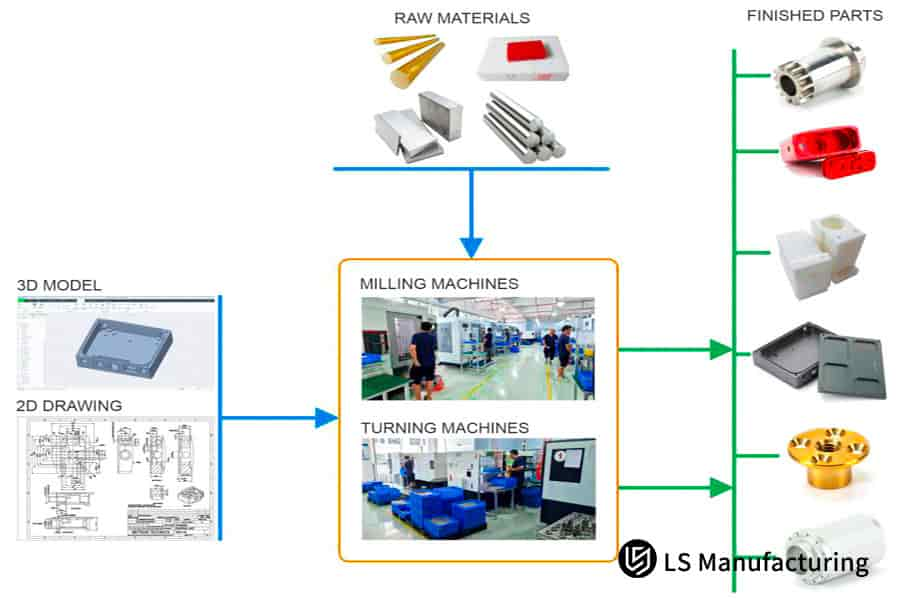

| Major steps to complete the work flow | Key Steps from Drawings to Parts | The standardized chain has been broken down, starting from 3D model designing and programming, then setting up, machining, post-processing, and quality inspection, through which one can see a birth of high-quality parts. |

| Key to Success | Pre-design collaboration | The focus is on how DFM (Design for Manufacturability) analysis can optimize part features in advance to significantly reduce manufacturing difficulty and cost while increasing success rate. |

| Advanced Processes | Revolutionary Solutions for Complex Parts |

The next section debates the analysis of how 5-axis simultaneous machining manages to process complex geometries with a number of facets in just one setup, reducing errors and saving costs while outperforming design limitations. |

| Selection and Service | How to Match High-Quality Partners |

The section below shall provide a critical rundown of assessing the technical capabilities, the list of equipment the machining providers have, their quality systems, and the lines of communication so that seamless project delivery is guaranteed. |

It systematically analyzes how modern CNC machining is transformed from a passive "drawing-based processing" service to the front-end collaborative partner in driving product success. The core value consists of guaranteeing the baseline production by process standardization, seeking leaps in quality and efficiency and freedom in design due to technological advancement: the very idea of "Design for Manufacturability" and 5-axis machining.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Actually, our workshop is a battlefield fighting against those tough-to-machine titanium alloys and high-temperature alloys for the manufacturing of parts in key fields: aerospace, medical treatment, and automotive powertrains. Every single thread and each surface tolerance will relate directly to flight safety, patient health, or ultimate performance. What we share with you is practical experience distilled from the successful delivery of tens of thousands of complex parts.

Material properties and process parameters discussed in this guide are based on hard evidence; most of the content closely refers to and follows the authoritative industrial standard from Metal Powder Industry Federation (MPIF). Advanced standards and best practices in areas like Additive Manufacturing (AM) are extended to integrated advanced manufacturing technologies that have been drawn upon. To this extent, this guide ensures its recommendations not only come tested by oil and chips from our workshop but also withstand technical scrutiny.

What you are reading here, therefore, is anything but superficial theory. Every insight, from tap selection strategies down to clamping solutions for complex thin-walled parts, comes from costs paid and successes finally obtained. We have written down these experiences in such a form as to give you a sure map from the front lines when one faces precision manufacturing challenges-one that will get it right the first time.

How Does CNC Machining Achieve Precision Manufacturing Through Digital Control?

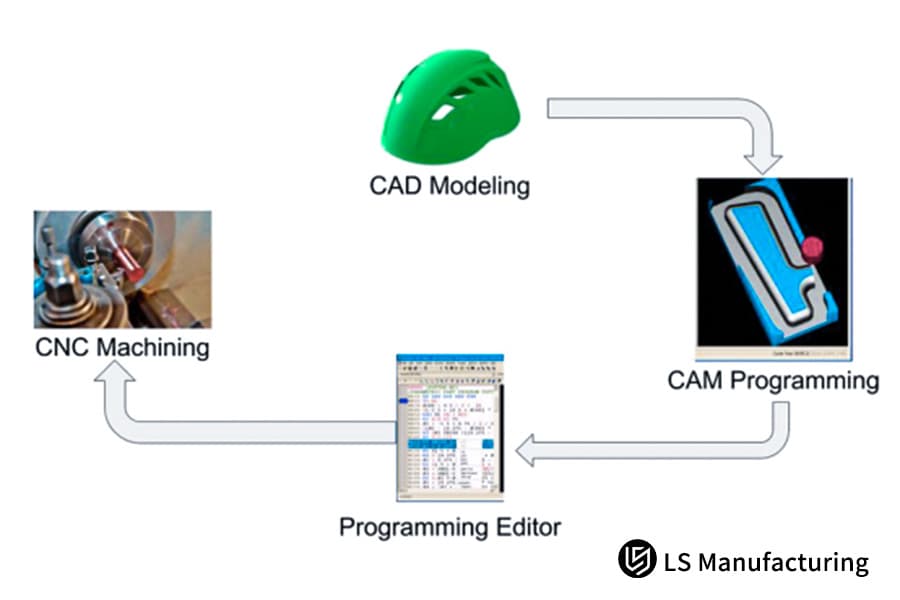

A precise manufacturing process via CNC machining work is accomplished through digitized control, whereby a computer guides factory equipment according to set manufacturing instructions. It begins with a digital blueprint that enables a seamless transition from design to a perfect finished product. It ensures there is high accuracy and precision achieved. The digital imperative is essential for a precise CNC machining process and quote.

- Digital Circuit to Machine Commands: This involves a process right from a CAD file, which must be converted to a CAM file into G-code. G-code can be considered instructions that relate to level, speed, and rate of feeding and can be a blueprint of the intended product on its own. The end result of this process affects the scope of your CNC services and quote.

- Precision in Motion: The control unit of the CNC can thus provide precision in motion, as it interprets commands issued by the programmer through G-code and then generates control signals that regulate the functioning of the servo motors involved in the axes motion. It is for this reason that a precision CNC machining factory in its motions.

- Closed Loop Precision: The models also involve the use of the closed loop feedback systems. The sensors also make efforts to ensure that they follow the current position of the tooling head. The sensors relate this to the definition of the actual movement. In a moment, the sensors also remove the deviation. The system also has an accuracy of +/- 0.01mm.

- Material and Tooling Synergy: The process optimizes the interplay between machine, cutting tool, and material. Parameters like spindle speed and depth of cut are calculated to minimize vibration and tool wear, which is essential for maintaining precision in high-volume or complex CNC machining jobs.

Therefore, the blending of the digitized translation services, motion control services, and corrective actions in the real-time environment is, henceforth, the cornerstone that has to be abode for the achievement of precision. On this particular issue, the collaboration of a capable partner for the CNC services and quote and a capable precision CNC machining factory is absolutely required for the achievement of a satisfying result.

What Special Needs Can Customized CNC Machining Services Meet?

These custom CNC machining services are for engineering problems, which can't be solved in conventional manufacturing operations. There's no need for mass production or problem-solving in specialization in custom CNC machining services. Mass production, as the name suggests, involves producing products in larger quantities, while problem-solving in specialization would require solving problems in specializing in a particular job. The most crucial areas where the advantages of custom CNC machining services can be listed are:

| Capability | Description |

| Complex Geometries | Machining of complex surfaces with deep cavities. Machining of thin-walled sections, which cannot be machined by conventional machining. |

| Specialized Materials | Materials such as Titanium or Inconel, or PEEK or Composites. Machining of Exotic Metals |

| Small-Batch Flexibility" | Rapid and affordable manufacturing from prototypes through small batch production without incurring tooling costs. |

| Integrated Solutions | It refers to the value-added solutions related to manufacturability, finishing solutions, as well as the various forms of value-added solutions related to the assembly of products based on total solutions. |

In a nutshell, the point that the cooperation with the CNC parts manufacturer with specific competencies is helpful in converting unique challenges into reliable and high-performance results, in so far as the custom parts machining is concerned, proves, as it were, the true value of the cooperation.

Figure 1: Integration of automatic robotic arm in modern CNC turning by LS Manufacturing

How To Choose A Reliable CNC Machining Service Provider?

Your choice of the qualified CNC machining supplier services may be assessed through the process with regards to the choice of the item, the item delivery, along with profitability. In case of a situation where the qualified supplier refers not only to a parts supplier but also to a solutions, mitigations, and peace of mind provider, the boundaries of the qualified supplier assessment refer to a whole wide range of factors, whereby in essence, the process actually includes more with regards to the cost assessment process.

| Evaluation Dimension | Key Considerations & Questions to Ask |

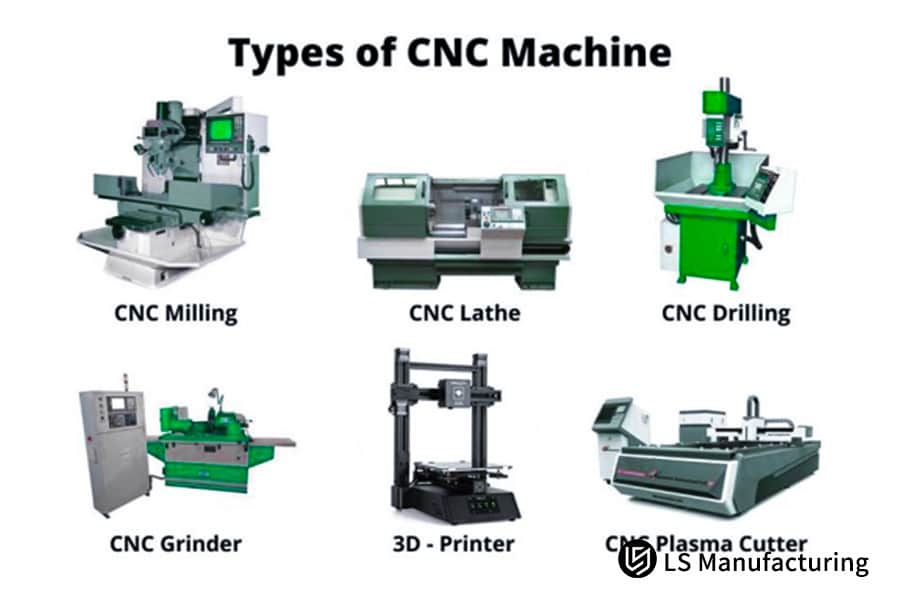

| Technical & Equipment Capability | Do they have the type of equipment (multiaxis machining, Swiss-style machines) that matched the complexity of the parts we were manufacturing? A precision CNC machining factory that is on the cutting edge of the industry will be equipped with the latest equipment that is commensurate with the parts you are manufacturing. |

| Quality Assurance Systems | What type of certification do they have (ISO 9001, AS 9100 certified, etc.)? What are their process inspection tools (CMM, optical comparator) and available document resources (FAIR, PPAP)? |

| Engineering Expertise & Service | How active is the company regarding Design For Manufacturability (DFM) input into designs? Assess the response and project management style, which needs to be an extension of yours. |

| Reliability & Business Stability | Can they deliver the lead times they quote in a reliable manner? Evaluate their production capacity, their supply chain, business stability. Can they deliver a good service to you, their CNC parts manufacturer. |

Therefore, a professional CNC machining supplier has to find a balance between technology use, quality, engineering collaboration, and reliable performance. In this manner, this aspect shall become a competitive advantage within your company because difficulties in manufacturing will be transformed into success.

What Are The Main Factors Affecting The Cost Of CNC Machining?

It is always essential that you have the understanding and knowledge regarding the factors that are primarily involved in the calculation for the CNC machining cost, for which you will be effective in the area related to budgeting and the optimization of cost. Even this entire process for calculating the cost can be accomplished by taking into consideration all the factors, ranging from the stages related to material cost to reaching the last stage for the inspection procedure. By virtue of the factors, you would be effective in the area related to optimization for your respective work.

- Material Selection and Utilization: Material Selection and Utilization: Natural Cost may vary depending upon the type, quality, and size of material being utilized. The Exotic Alloys are going to be costly compared to other aluminum alloys. Furthermore, efficient nesting and machining strategies that minimize waste directly lower material expenses, a key consideration in any CNC machining process and quote.

- Part Complexity and Machining Time: The higher level of complexity in the parts with respect to geometry, tolerance levels, pockets, and thin walls makes the programming level complex. The levels at which machining speed has to be reduced are also higher. Machining time is also increased with higher costs. Here is where simplifying geometry has become economically viable.

- Labor, Programming, and Setup: While highly automated, CNC machining still requires skilled labor for programming, setup, and supervision. Complex first-part programming and fixture design add to initial costs. However, for larger volumes, this cost is amortized, improving the overall value proposition of the CNC services and quote.

- Secondary Process & Finishing: The cost would be higher than the milling cost and turning cost. There could be some secondary processes like deburring, heat treatment, anodizing, and plating that could increase the overall cost. It would be ensured that there are no secondary processes if satisfactory specifications are achieved.

In summary, optimizing CNC machining cost is a collaborative exercise between design efficiency, material choice, and process planning. An accurate and transparent CNC machining process and quote should detail these factors, enabling you to identify areas for trade-offs. Partnering with a supplier who provides clear CNC services and quote breakdowns and proactive DFM advice is the most effective strategy for achieving high-quality parts within budget.

What Key Technological Capabilities Are Required For The Manufacturing Of Precision Parts?

Where high precision components are being manufactured, it requires more than machine skills. It is evident that for the manufacture of precision components, there is a certain environment that mandates the use of cutting-edge technology, precision, and a lot of technical know-how. It can make the difference, and an average machine shop may become different from a precision partner.

Advanced Machining Platforms and Control Systems

In the case given, it can safely be assumed that the background or basis technology provided by the likes of multi-axis machining platforms requiring control will be available. This machining platform will require the likes of thermal correction technology, vibro-damping technology, and robust machining technology for it to work effectively. A precision CNC machining factory will require such technology for it to provide a machining facility with micron-level precision.

Metrology and In-Process Verification

Precision is meaningless without verification. Advanced metrology tools—like Coordinate Measuring Machines (CMMs), optical comparators, and surface profilometers—are essential. Implementing in-process measurement and Statistical Process Control (SPC) allows for real-time corrections, ensuring every custom parts machining order meets stringent specifications from first part to last.

Process Engineering and Optimization

Technical mastery involves developing and refining stable machining processes. This includes expertise in cutting tool selection, optimal fixturing solutions, tailored machining parameters, and effective chip management. An experienced CNC parts manufacturer leverages this knowledge to optimize cycle times, enhance surface finish, and guarantee part reliability.

Material Science and Environmental Control

It is also important to appreciate the characteristics of CNC machining materials as far as stress relaxation, expansion, and machinability are concerned. There may also be a need to control factors such as temperature, humidity, and cleanliness during manufacturing, in order to ensure that there are no other variables which may affect the size of the manufactured part.

It is a versatile enterprise that requires a need for sophisticated equipment, scientific measurement, process knowledge, and understanding of the environment. Towards the end, the most important consideration for projects that can’t afford failure will be the search for a capable and qualified precision CNC machining factory that embodies such qualities in the role of a good CNC parts manufacturer.

Figure 2: Key CNC equipment enabling high-precision manufacturing by LS Manufacturing

Case Study Of LS Manufacturing's 5-Axis Machining Of Aerospace Titanium Alloy Structural Components

The LS Manufacturing was presented with a critical problem statement in the area of manufacturing, which was being encountered by the most renowned aerospace company. The client needed to manufacture a huge and complex structural component made up of titanium alloys. However, their existing method for machining was not sufficient to some extent. The gigantic challenges were: there was no repeatability in precision, a long time required for production, and a substantial rise in cost factors; all these threatened this task to a tremendous extent.

Client Challenge

There were several setup steps required in the production process of the client using traditional manufacturing. Moreover, the present misalignment is not within the required tolerance standards. The production was taking a long time for machining. There was very fast wear and tear of the tooling machine due to machining of the titanium component. Therefore, there was inefficiency related to production. As a result, there was a need to apply innovation during the production process.

LS Manufacturing Solution

Our engineering experts have also designed a strategy that has been created with innovative custom CNC machining services. The strategy employed the use of a machine with high torque and 5 axes to completely machine one piece at a time. The strategy aimed to get rid of any problem created by the positioning error. On the other hand, the strategy for optimizing machined paths, speed, and cooling with titanium machining eliminated the machining time and the lifetime of the machine. The strategies employed with the use of CNC machining are linked with those employed by an expert precision CNC machining factory.

Results and Value

The outcome of this solution is nothing less than revolutionary. The output generated by the manufactured parts was much better than what the customer required, which is at perfection levels concerning repeatability. It is quite astonishing to know how, despite achieving a net improvement in machine efficiency by 40% in machining using a single set-up technique with 5-axis, there has been a decrease in production cost by 30% through optimized process parameters.

It is through the leverage of the benefits found in the capabilities as a precision CNC machining factory where we can transform a bottleneck found within the manufacturing process itself into a source where the output provides a significant advantage to the aerospace customer, which finds the capabilities through the leverage of the benefits which we possess within the capabilities for the custom CNC machining services.

Are you looking to improve your CNC manufacturing solutions? Click on the link below for a customized quote.

How To Ensure Consistent Quality In Small-Batch Processing?

Small production by lots requires a quality control task which cannot be adequately accomplished except with a robust and adaptable quality control procedure. It is a task which requires extensive process control and is a verification process which has to be strictly adhered to, from commencement at the end to completion to ensure that all products meet and fulfill the same standards. The task of quality control is one which truly tests a manufacturer’s metal.

- Standardized Process and First Article Inspection: When the concept of a locked-down process is contemplated, it requires having a documented process initially. First article inspection is an integral process wherein the utilization of CMM is required for the inspection of the first article with the specification described in the drawing. This is used for the machining of the custom parts machining job.

- In Process Monitoring and Control: Unlike high-volume processing, the skill level of the operator plays a crucial role in the monitoring and control of the in-process for small batches rather than completely depending on automation. Process control involves the observation of key characteristics, tool wear, and the stability of the machine within a predefined time interval. For a credible CNC parts manufacturer, a process point where the observation of any deviation in the process has to be accomplished instantly to avoid the production line deviating.

- Documentation and Traceability: Traceability is required for every lot or for every component in many cases. The type of documentation that is supposed to be submitted is the certification of the material itself, the results of the inspection process, and the machine records. The traceability in a lot is very important. It is a strong quality that is possessed by the CNC machining supplier.

- Closed-Loop Feedback for Continuous Control: The outcome of the final inspection is not archivable, as it is further diverted to other production and related engineering sections. The only way that control over production can be maintained is through taking proactive steps based on size-related data of a production process that is short in nature.

In a nutshell, quality in small lots is a function of a quality process characterized by rigorous start-up validation and a culture of formal documentation and continuous feedback. For companies seeking a quality parts machining experience with custom parts CNC machining, engaging a quality CNC parts manufacturer that operates as a CNC machining supplier assures those companies seeking quality custom parts machining services.

Figure 3: An overview of the fundamentals of CNC and automation by LS Manufacturing

What Are The Complete Steps In The CNC Machining Service Process?

Success in CNC machining will be facilitated by transparency in the whole process. At LS Manufacturing, we have a well-organized process that will turn your concept into the part you want. Because of risk reduction reasons, the organized process is project-oriented. Understanding this process is important for attaining the smooth relationship needed.

- Initial Consultation and Feasibility Analysis: Once the in-depth project review has started, we will examine your 3D designs to discuss concerns regarding manufacturability, alternative materials, and problems that may be confronted during manufacturing. This iterative step sets the basis for an elaborate and accurate CNC machining process and quote.

- Process Planning & Digital Prototyping: The subsequent phase is the creation of the whole production process once the project or design idea has been accepted. This involves the selection of the best routes to machinable areas using the best CAM available. Moreover, the creation of the digital prototype can include the simulation of collisions. This is very essential in the context of the delivery of the best custom CNC machining services.

- Precision Production and In Process Monitoring: Now that the plan is finally prepared, the process goes further on the shop floor. The component goes further to get machined on highly specialized equipment of the CNC category. That step is the implementation of the plan with specifications where the designed product goes into the physical world.

- Final Quality Assurance/Post-Processing: This is the last step where the final quality check of the machined product is completed using CMMs. Other secondary specifications, deburrs, and other processes such as heat treatment or finishing may have to be met. At this stage, the product can be shipped and thus complete the agreement on the use of a CNC service and quote.

In conclusion, briefly, with regards to CNC machining services, it can aptly be said that, in line with consultation, digital planning, product development, verification, right from the initial CNC machining process and quote to the point of shipment, our end-to-end approach fully encompasses this. In thus starting off in such a structured and full way, we can be sure that predictability and traceability, together with peace of mind, will be guaranteed with custom CNC machining services.

Figure 4: End-to-end flowchart of the CNC precision machining journey by LS Manufacturing

How To Obtain An Accurate CNC Machining Quote?

It is effective project management to begin with the attainment of the right and appropriate CNC machining cost estimation. Right cost estimation means appropriate understanding on the side of the supplier about the details. Cost estimation can be either the beginning or most pivotal step in formulating an efficient partnership relationship in the matter of suppliers. Aside from proper cost estimation, other steps that offer easy ways a client may attain an appropriate quote include:

Enable Complete and Accurate Design Data Submission

The key to an accurate quote is complete information. This includes full drawings with geometric dimensions and tolerance information in 2D form as well as the source 3D CAD file. In order for your request for CNC services and quote to avoid misunderstandings and costly reworks down the line, do not forget to add material characteristics, surface finish, and any additional post-processes.

Identify Quantity and Lead Time Requirements

Volume and schedule are major costing considerations. It is necessary clearly to specify just how much is required, be it prototyping, low-volume, or production quantities, as this applies to economies of scale. The required lead time will influence CNC machining process and quote since faster turn-around may necessitate exclusive use of the machine.

Partnership for Design for Manufacturability

Consult the supplier's engineering team prior to finalizing the quote to perform DFM analysis. Sometimes, even for a seasoned manufacturer, a contractor can identify a few straightforward, non-critical changes in the design that ensure much easier machining, shorter cycle times, and less scrap material, which eventually goes a long way in having a great effect on the final CNC machining cost.

Choose a Transparent and Reputable Partner

A trustworthy manufacturer will provide a detailed quote breakdown, not just a bottom-line price. Look for a supplier that outlines cost components such as material, machine time, setup, and secondary operations. This clarity in the CNC machining quote allows you to understand exactly what you are paying for and identify potential areas for value engineering.

In summary, achieving an accurate quote is a collaborative effort. It requires providing complete design data, clear project parameters, and openness to expert DFM feedback. By partnering with a transparent supplier who provides a detailed CNC services and quote analysis, you gain not just a price, but a clear understanding of the CNC machining cost drivers, enabling smarter budgeting and a smoother project execution from the very start.

FAQs

1. What is the largest machining size possible with CNC?

Our largest machined dimensions are 2000 mm, 1000 mm, and 500 mm. Perhaps it might fulfill needs for various large and medium-size structural components. Its mention would be required depending upon the nature of the structure for the component as well as on the machine being used. In heavy components, it needs to be customized.

2. For an average group of complex parts, how is the total production cycle determined?

In the case of relatively complex components, usually, the standard lead time would range between 2 to 4 weeks. Depending upon the level of complication of the component, the level at which machining has been done, as well as at which level production has been carried out for the priority component, we can come back to you with a standard lead time, which may possibly be applicable to your project.

3. What is the minimum order quantity?

While we are catering to their demands, we also allocate for different production outputs depending on their lowest order requirement of 10 units. Of course, it will complement their product developments, prototype creation, and base model production output for their products because it will address their problems related to the output expenditures for product testing and launching.

4. Can you provide quality records of the machining process?

In fact, we can. And also, if required, the following traceable documents for the whole process concerning the quality of the product might be provided: the Inspection Report for the first article, the Inspection Report for the critical process, and the Inspection Report for the whole product.

5. How do you ensure machining accuracy?

The “Equipment-process-inspection” elements are fully implemented in order to have accuracy, with the incorporation of advanced equipment like five-axis machines, followed by the optimization of the process parameters, and finally the process with the use of equipment like coordinate measuring machines.

6. Do you have rush processing?

We can perform flexible rush production. Also, in instances that the customers need an urgent demand, we also can evaluate and restructure the production program so that we may optimize and optimize the lead time into delivery. Specifically, this is subject to evaluation based on the current production capability concerning the possibility of rush production.

7. What documents are required for the new project?

For the goal of efficiency concerning project startup, we suggest, concerning the 3D models of the pieces, that we receive, by example concerning the format of STEP/IGES, aside from the engineering designs. Thence, there is a possibility that a solution within the rush demand concerning the services may be provided.

8.How can I get a detailed quote?

For these, we allow specifications regarding the possibility of specifications described within the format of 3D, technical specifications, and volume, through the agency of our contacts provided within our website or via email. These we then analyze within the time span of 24 hours, then send back a detailed quote.

Summary

All the way through this, the entire guide, we do every attempt to then focus concerning all the process, every process characterizing an obligatory series of steps concerning each process, principal, along with the most appropriate important steps concerning directly linked CNC machining. Truly, concerning this, we classify, concerning then, that Your relationship with a professional and knowledgeable supplier is the foundation of every single process that has implications related to quality, cost, and ultimately, related directly to success within your projects.

If your project involves CNC machining and precision and reliability are of paramount importance, please contact LS Manufacturing immediately. We offer free technical consultation and guarantee a response within 24 hours.

Get a personalized quote now and unlock the manufacturing potential of your products. Click to contact us!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.