In the realm of modern manufacturing, CNC turning programming plays a pivotal role in the production of high-precision components. This sophisticated method of machining involves the use of computer-controlled devices to create intricate parts and pieces, ensuring meticulous accuracy and consistency. As CNC turning program continues to evolve, it has become increasingly critical for a wide range of manufacturing sectors, significantly contributing to the efficiency and quality of the end products.

The power of CNC turning programming can be appreciated in the production of CNC turning parts, where the precise removal of material from a workpiece is achieved through a turning process. This is fundamental in the creation of items that demand strict tolerances and rounds off any industrial requirement needing exact specifications. Whether it's through a CNC turning center or a more personalized CNC turning service, these machines deliver exceptional results in replicating designs to the minutest detail, allowing businesses to execute projects swiftly and effectively.

Moreover, CNC turning & milling expands the capabilities even further by integrating additional processes to handle more complex designs. This adaptability makes it possible to produce intricate components that require multiple machining techniques. The synergy between CNC turning and milling allows manufacturers to cover a wide range of machining needs and applications, making it indispensable in automotive, aerospace, and medical equipment industries, where precision engineering is non-negotiable.

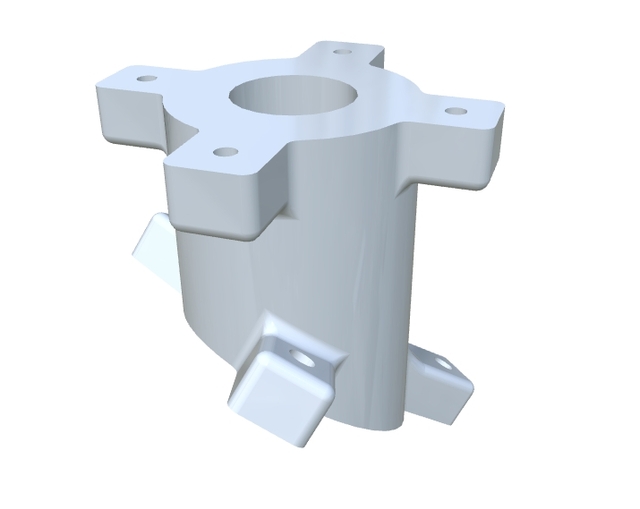

Amidst the ever-progressive landscape of CNC machining, products like the Advanced Precision Tube have come to the fore. With its precision-engineered design, this state-of-the-art product exemplifies the finest in CNC turning integration. Made with the latest materials for unmatched durability, the Advanced Precision Tube is not only robust but also versatile—a perfect fit for diverse industrial applications. Its sleek, modern appearance complements its practical functionality, setting a standard for reliability in high-performance environments. As industries continue to thrive on innovative solutions, components like the Advanced Precision Tube highlight the critical role of CNC turning in meeting these evolving demands.

CNC Turning Programming: Essential for Modern Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Custom CNC Turning Services for Precision Manufacturing

CNC Custom Machining: Precision Solutions for Industries

Top CNC Machining Parts Manufacturer for Precision Needs

Achieve Precision with Custom CNC Turning Services

Transforming Industries with Custom CNC Turning Services

CNC Turning Services: Precision Crafting for the Future

CNC Machining: Precision in Industrial Components

CNC Turning Machines: Revolutionizing Precision Manufacturing

CNC Turning Services: Innovative Solutions for Precision Engineering

CNC Turning Programming: Essential for Modern Manufacturing